P/N 92974, Rev. 1 Page 35

9. Mount the tack weld plates

to the spherical bearing

mounting brackets. If more

clearance is required, weld

1" x 1" x 6" (12 mm x 12

mm x 72 mm) the tack weld

blocks to the tack weld mounting spacer plates.

10. Temporarily clamp the bracket assemblies to the workpiece. Leave enough

room to remove the cones after the brackets are welded in place.

11. Check that the setup cones are still securely in position.

12. Securely weld all standoffs and brackets in place.

13. Remove the temporary clamps.

14. Loosen the set screws in the setup cones.

15. Remove the bar from the brackets and remove the setup cones.

16. Carefully reinstall the bar through the mounting brackets.

If necessary, precisely align the bar

by doing the following:

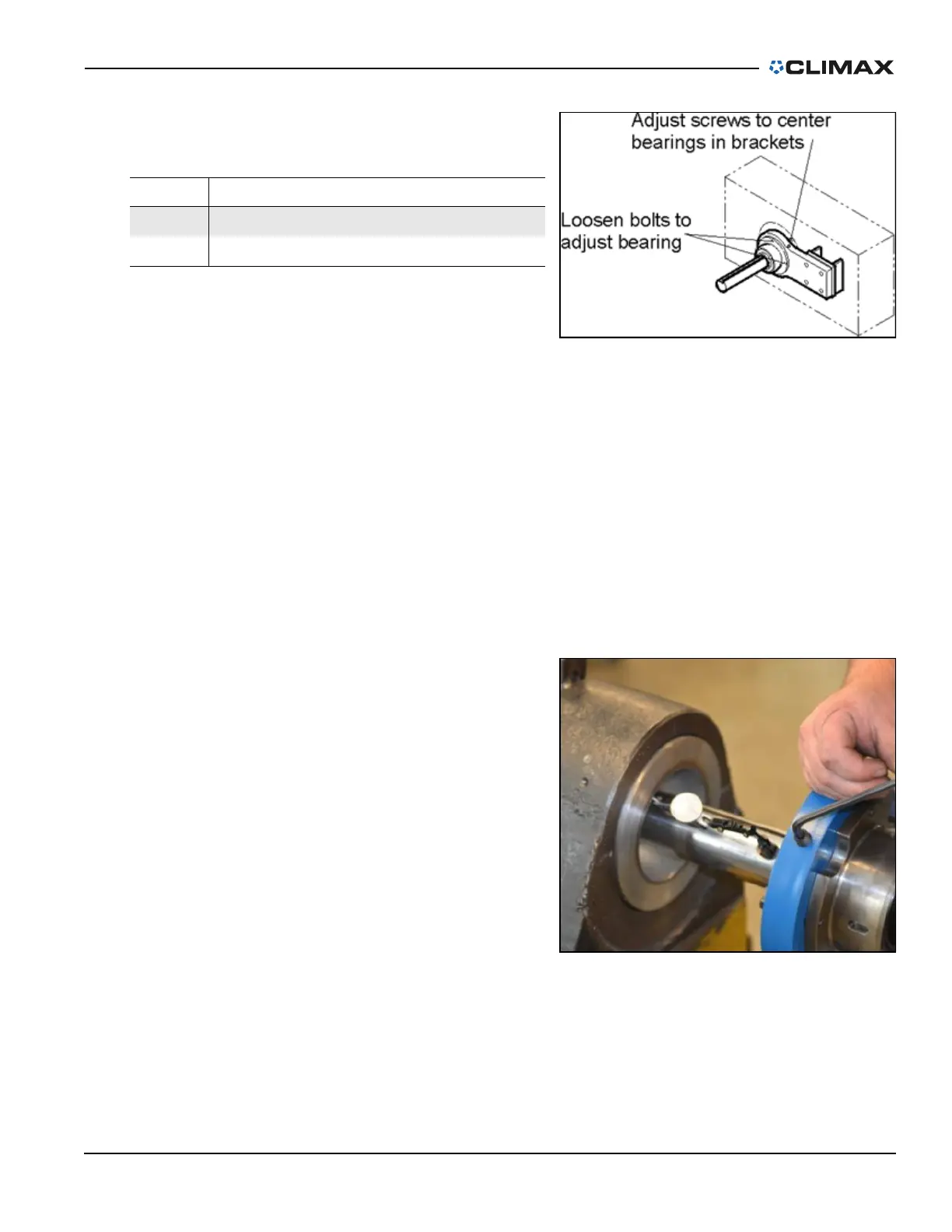

1. Loosen the hex bolts hold-

ing the bearing to the

bracket.

2. Attach a dial indicator to

the bar and touch the stylus

to the workpiece ID.

3. Rotating the bar, adjust the

set screws to center the bar.

4. Tighten the hex bolts to

keep the bearing and the bar

in place.

3.3.2 Tooling and tool head assembly

These machines are designed to cover a wide range of boring applications. The bar

design allows for inserting a tool bit into the bar or clamping a tool head assembly

TABLE 3-3. SPHERICAL BEARING IDENTIFICATION

Number Component

1 Loosen bolts to adjust bearing

2 Adjust screws to center bearings in brackets

FIGURE 3-5. POSITIONING THE SPHERICAL BEARINGS

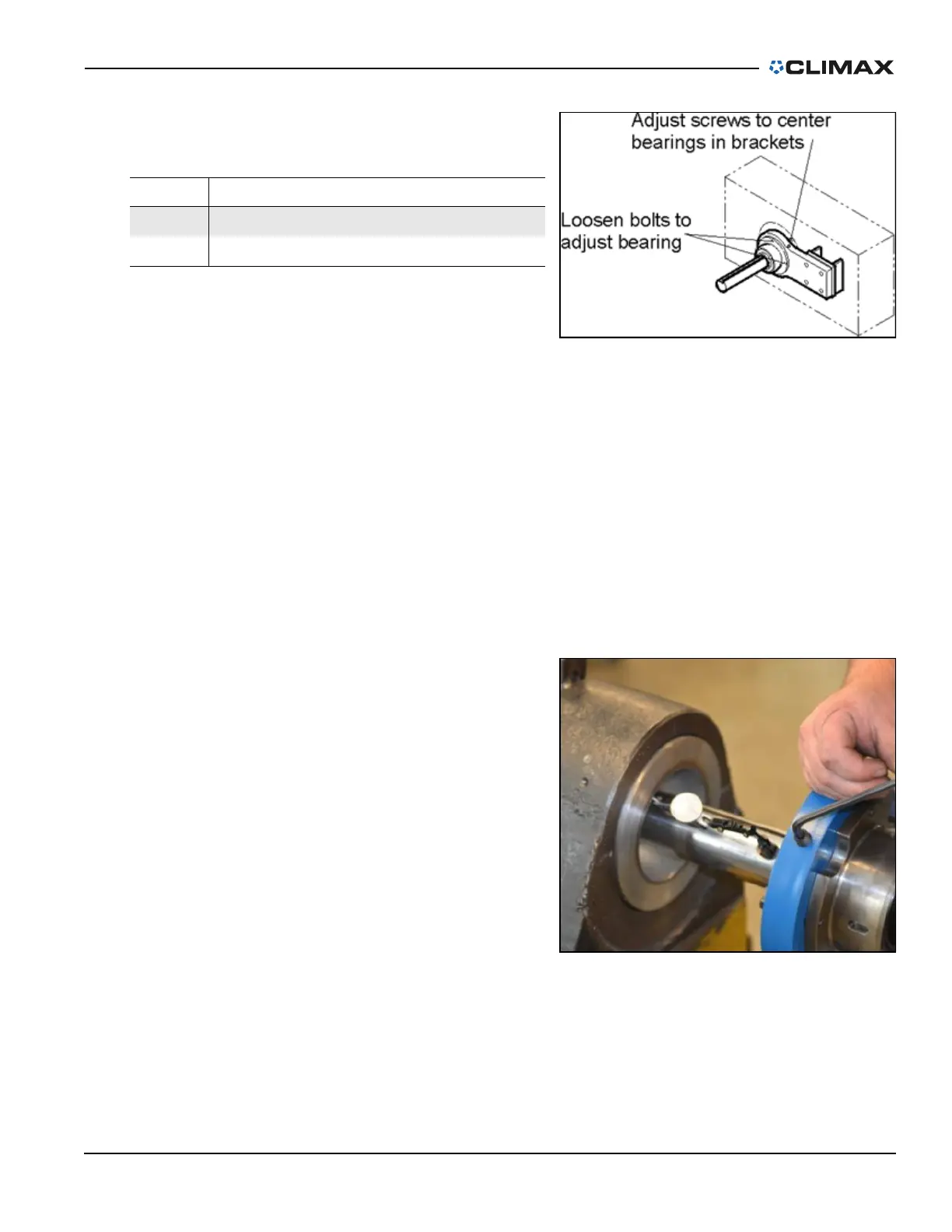

FIGURE 3-6. ALIGNING THE BAR

Loading...

Loading...