P/N 92974, Rev. 1 Page 59

5.3 MAINTENANCE TASKS

Maintenance tasks are described in the following sections.

5.3.1 AFU

Clutch performance may be compromised if the machine has been “crashed,” has

seen over a thousand hours of operation, or is operated in a dirty environment.

If the axial feed fails, check that the shear pins are intact. Extra pins are included

with the assembly. The pins must be in place (notched end out) to engage the feed.

Freezing temperatures may cause the axial feed box to run sluggishly.

5.3.2 Boring bar

Check the bar regularly for nicks, cuts, or abrasions. Dress the bar smooth if neces-

sary. A bar with nicks or gouges can damage the bearing supports and RDU

beyond repair. Wipe the bar clean with solvent to remove dirt and chips.

5.3.3 Hydraulic power system

For information on maintaining the hydraulic power system, see the manufac-

turer’s documentation for your hydraulic system.

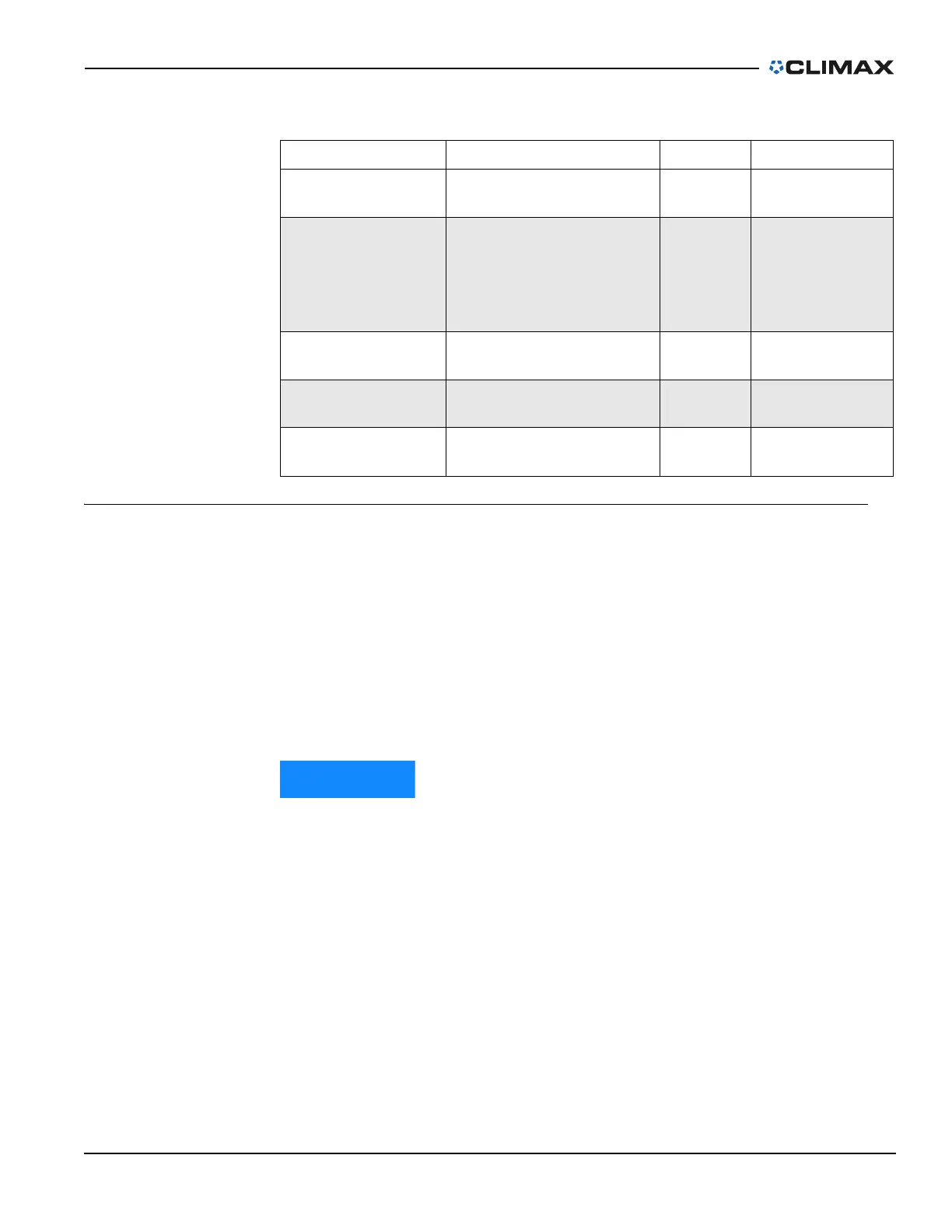

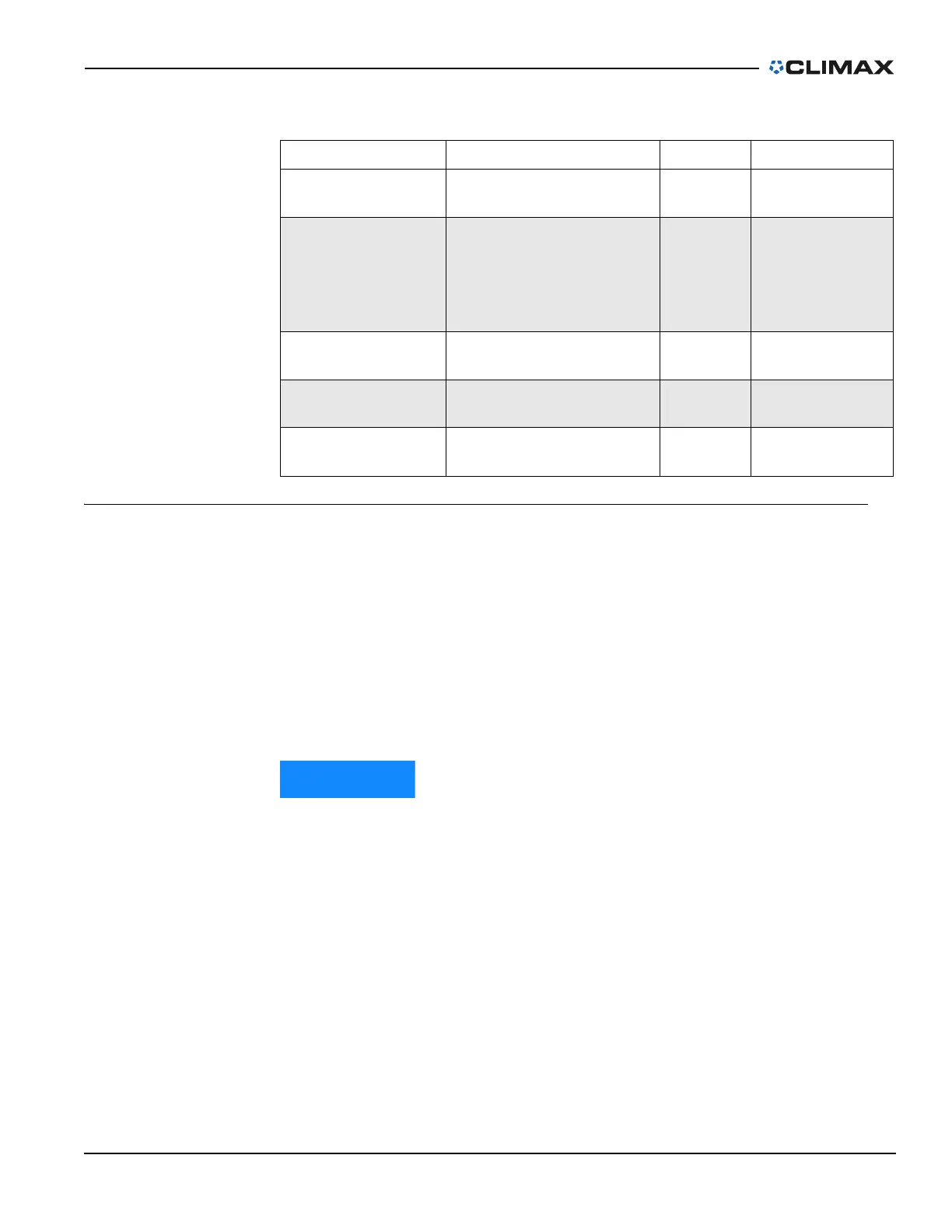

Air motor AW 32 6 oz

Per use through

the lubricator

ACME screw

Boring bar

Tool heads

Unpainted surfaces

WD 40

As

required

Per use by hand

Cutting fluid DoAll AL2000

As

required

As required

Long-term rust pre-

ventative

LPS-3

As

required

For storage more

than 3 months

Tool bits, work piece Koolkut

As

required

Per use by hand

TABLE 5-2. APPROVED LUBRICANTS (CONTINUED)

Application Area Lubricant Quantity Frequency

Loading...

Loading...