P/N 92974, Rev. 1 Page 37

Do the following for standard setup, referring to Figure 3-8 on page 36:

1. Using the clamping screw, secure the tool head tightly to the boring bar.

2. Select either a HSS or a brazed carbide tool bit.

3. Position the tool head on the bar with the open side of the tool slot toward

the workpiece in the feed direction.

4. Slide the tool bit into the tool head with the cutting face toward the tighten-

ing screws. This will position the cutting face at or slightly below the cen-

terline.

Tool bits are either right-handed or left-handed. This allows for feeding

both directions with the same rotation direction.

5. Use a dial indicator to set the tool bit to achieve the desired depth of cut.

The maximum recommended cutting depth is 0.125" (3 mm). Tighten the

tool bit mounting screws.

CLIMAX offers a bore measuring tool specially built for setting the tool

bit height and checking the actual bore diameter. Contact CLIMAX for

more information on this tool.

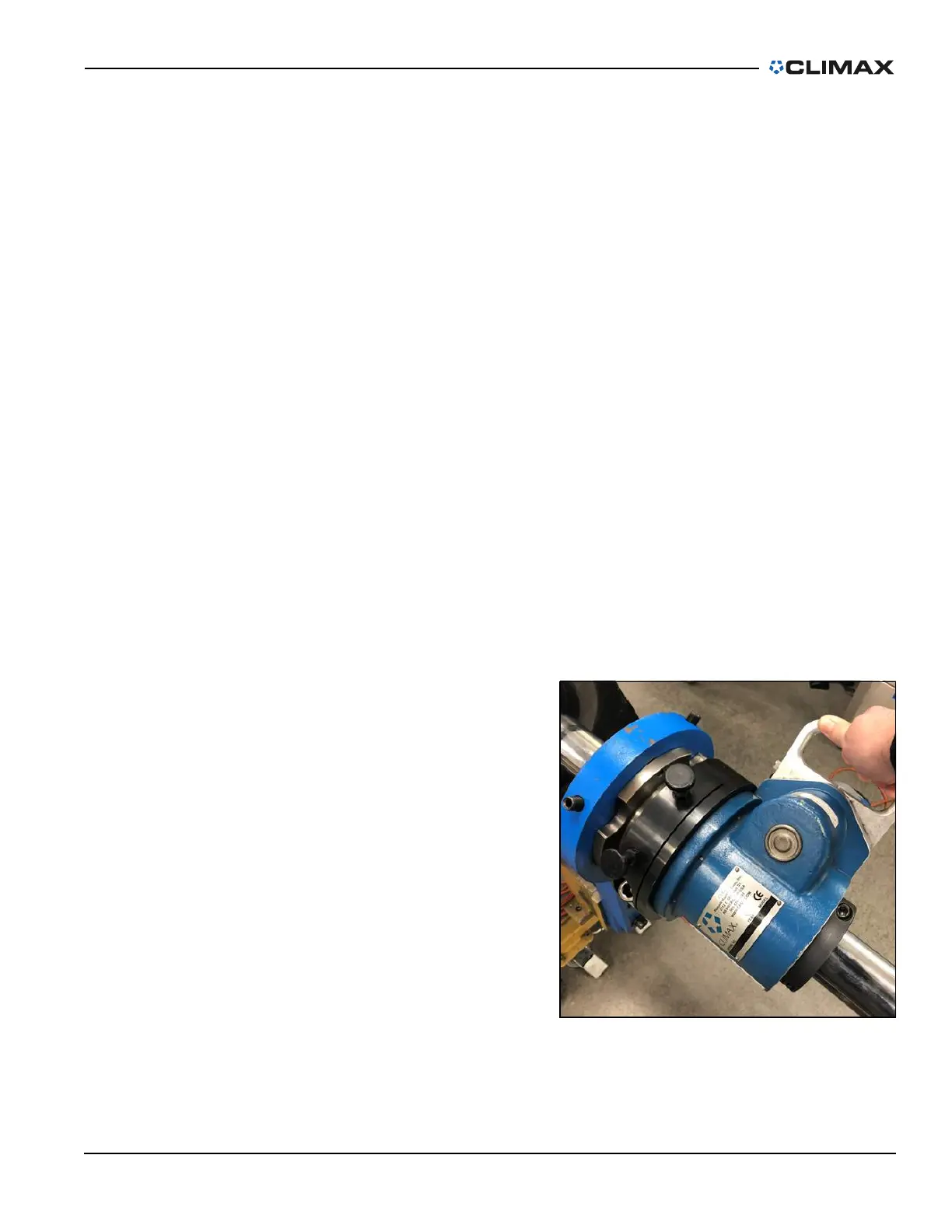

3.3.3 RDU and AFU assembly

The compact RDU may be placed

anywhere along the bar.

Before beginning set-up, plan the

relationship between the RDU,

motor, and axial feed unit (AFU) to

allow for enough space.

FIGURE 3-9. POSITIONING THE RDU

Loading...

Loading...