11

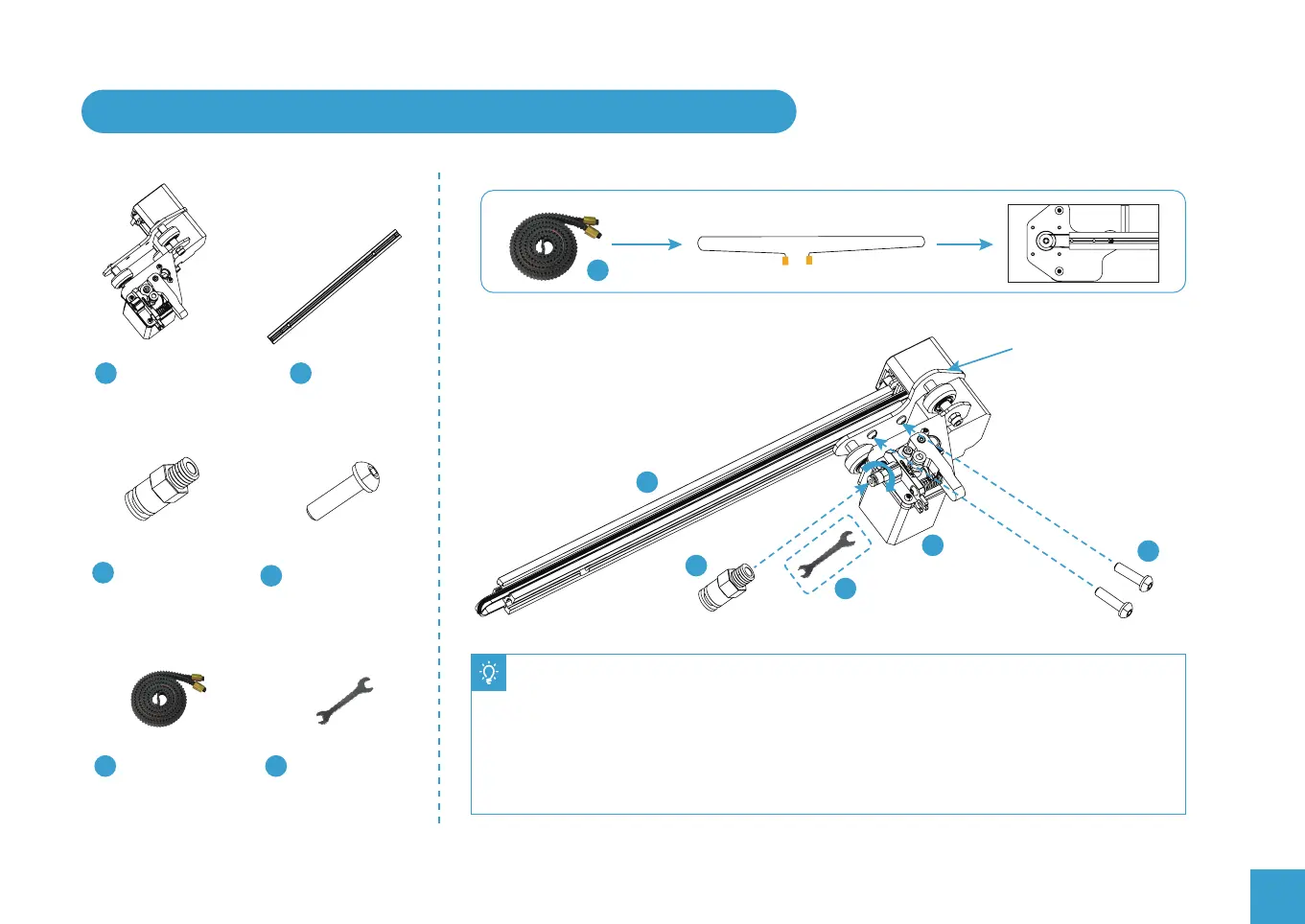

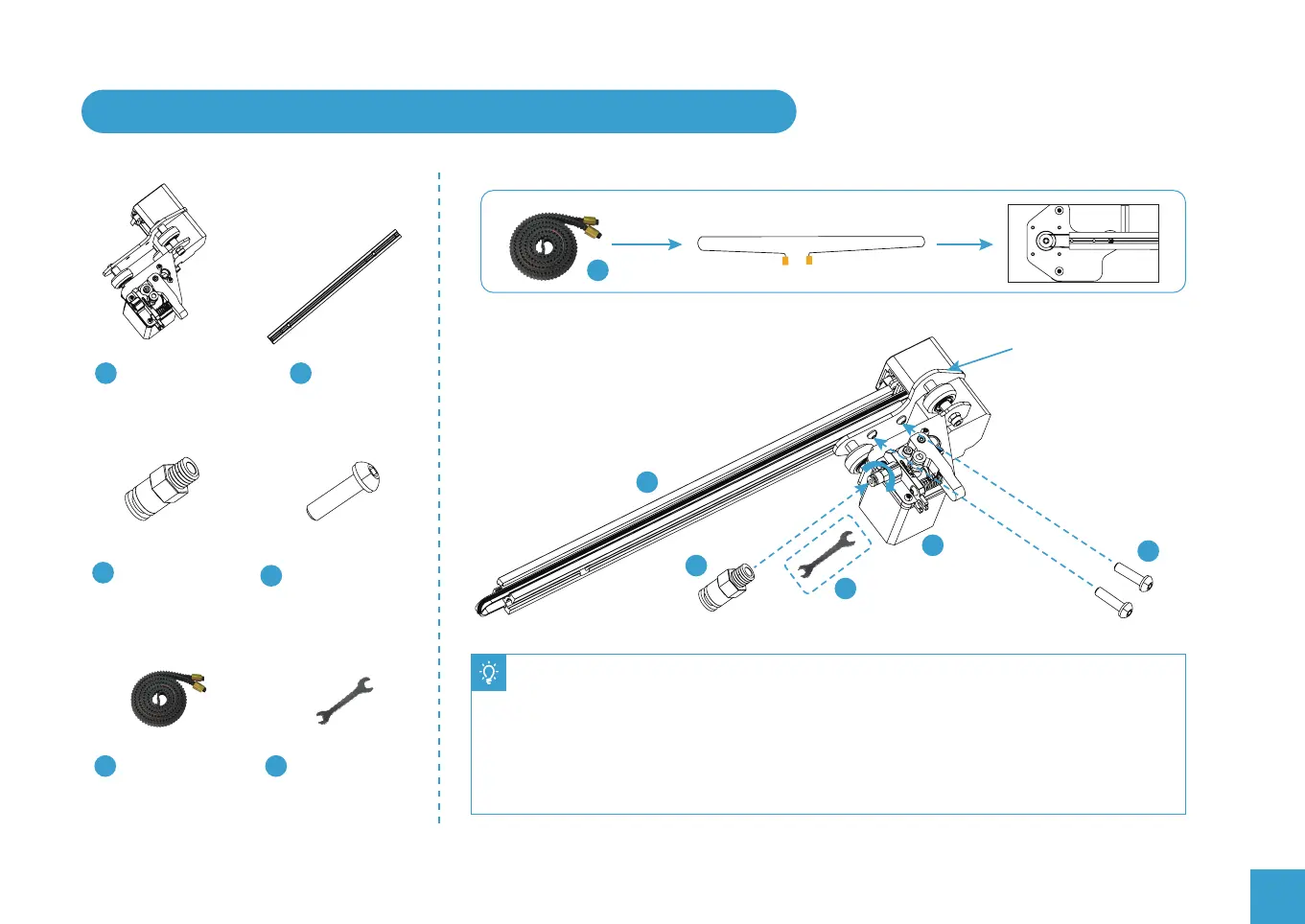

3. Install Pneumatic Joint, XE-axis Assembly and Drive Belt

8

8

12

12

X-axis

Profile x 1

XE-axis

Assembly x 1

Install the drive belt

around the pulley.

23

23

Bowden Tube

Connector x 2

32

32

Hexagon Socket

Flat Round Head

Spring Washer

Combination

17

Drive Belt x 1

25

25

Wrenches and

Screwdrivers x 1

17

● Tighten the Bowden tube connector firmly into the Extruder using an open-end wrench.

● Align the bolt head on the XE-Axis Assembly into the hole on the X Axis profile.

● Secure the XE-axis Assembly to the X-Axis Profile with two M4X16 screws. (Insert the

Allen key through the holes on the outer plate).

● Install the Drive belt round the pulley inside the XE-axis Assembly with the toothed side

round the pulley as shown above.

Loading...

Loading...