13

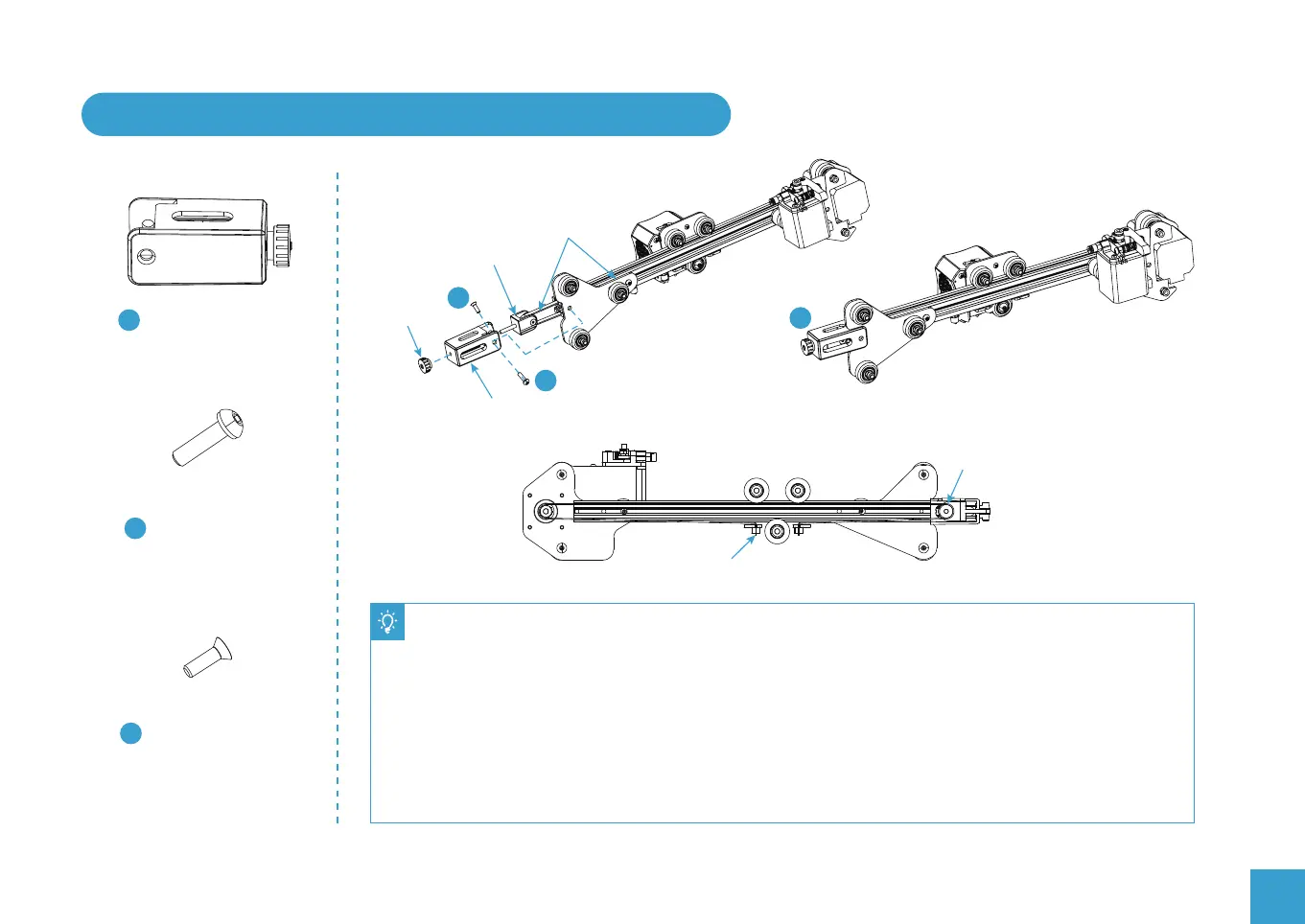

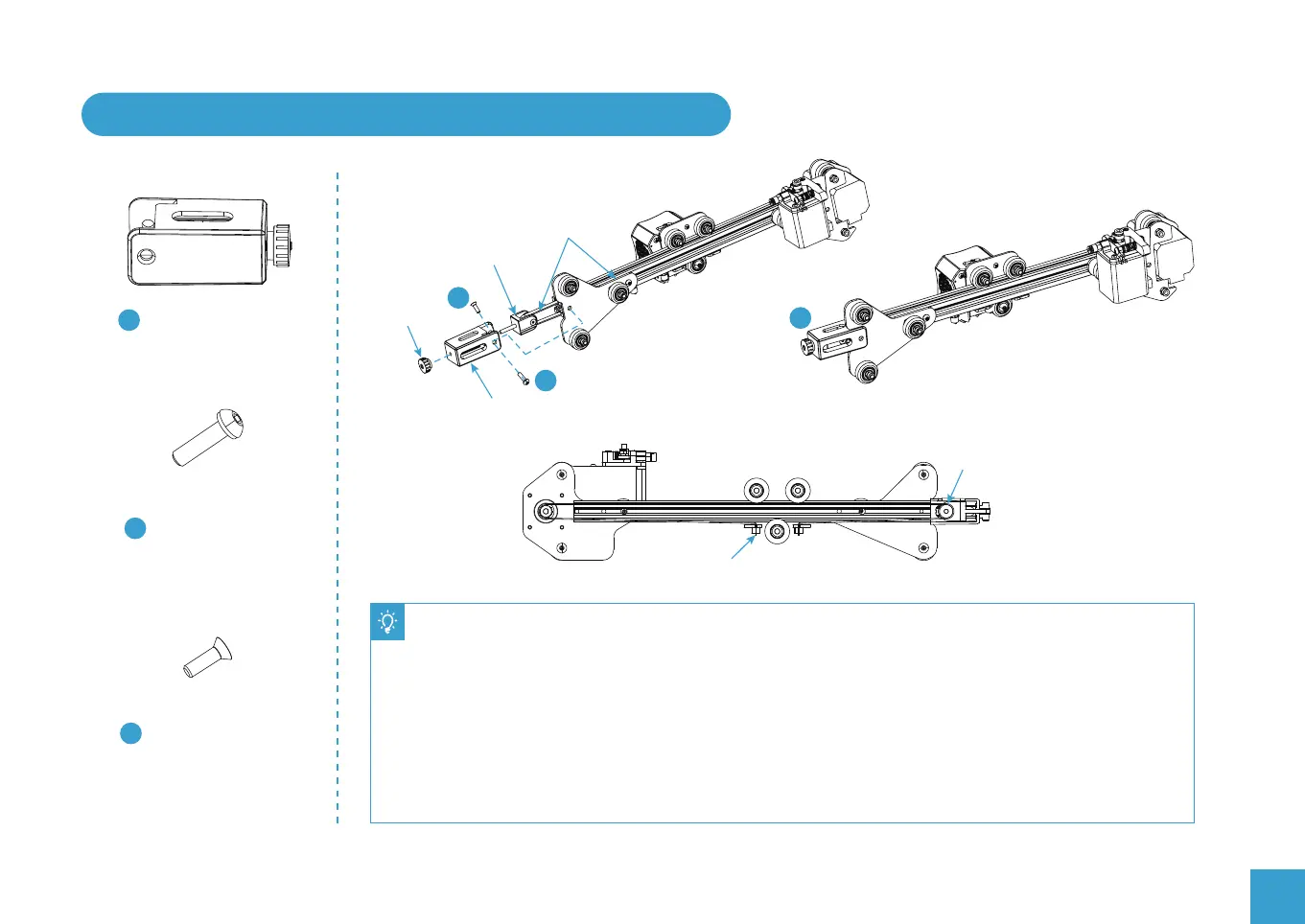

5. Install X-axis Tensioner and Connect the Drive Belt

35

35

Hexagon Socket

Countersunk Head

Screw (black)

M4X14 x 1

32

32

Hexagon Socket

Flat Round Head

Spring Washer

Combination

5

5

X-axis Tensioner x 1

Drive Belt

copper sleeve

Installation Illustration Completed installation

Tensioner

block

Tensioner block

X-axis tensioner base

Tensioning

Knob

Back View

● Undo the tensioning knob and remove the tensioner block.

● Thread the drive belt around the pulley making sure it has not twisted and push the pulley back into the

tensioner base making the alignment is as shown in the picture above.

● Screw the tensioning knob back into place by couple of turns.

● Attach the Tensioner base to the profile Z Axis Roller Bracket assembly with a M4X16 screw on one side

and the countersunk screw (in the Tensioner block bag) on the other, both these screws use the same

threaded hole in the profile.

● Secure the ends of the drive belt by sliding the belt into the slots in the Nozzle assembly as in the picture

above.

Loading...

Loading...