4 — PROGRAMMABLE PARAMETERS

Curtis AC F4-A Motor Controller – August 2020 Return to TOC

pg. 114

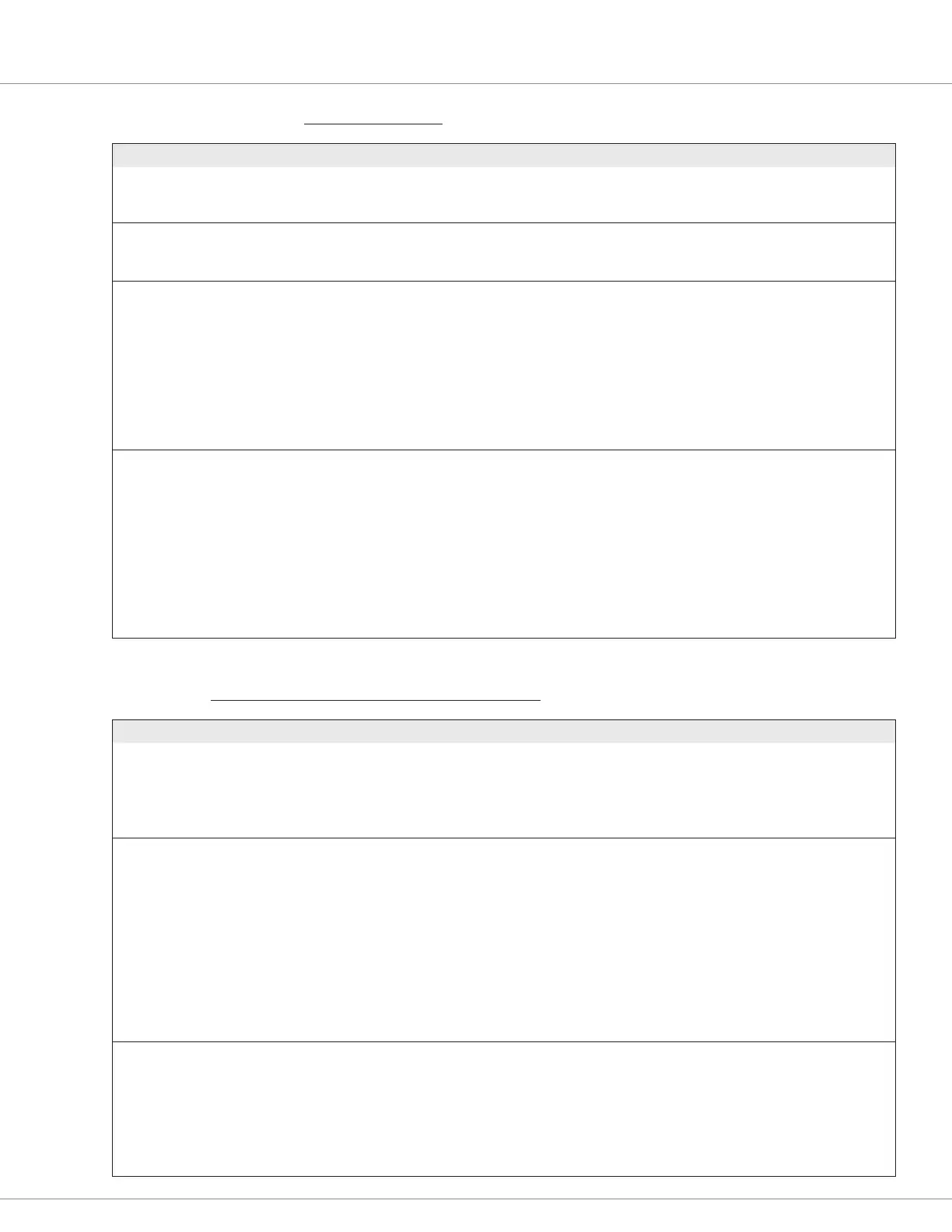

AC MOTOR SETUP — QUADRATURE ENCODER MENU

PARAMETER ALLOWABLE RANGE DEFAULT DESCRIPTION

5V Output Enable

Ext_5V_Output_Enable

0x36A8 0x00

On/Off

On/Off

On Enables the 5V Power Supply Output.

12V Output Enable

Ext_12V_Output_Enable

0x36A7 0x00

On/Off

On/Off

Off Enables the 12V Power Supply Output.

Encoder Steps

Encoder_Steps

0x34E7 0x00

32 – 2500

32 – 2500

64

[PCF]

Sets the number of encoder pulses per revolution. This must be

set to match the encoder; see motor nameplate.

Note: Do not change this parameter while the controller is

powering the motor. Changing this parameter always results in

a Parameter Change Fault (fault code 49). Clear it by cycling the

keyswitch (KSI cycle). The Parameter Change Fault protects the

controller and the operator.

Adjusting this parameter can be hazardous; setting it improperly

may cause vehicle malfunction including un-commanded drive.

Review the Commissioning Chapter when setting this parameter.

Swap Encoder Direction

Swap_Encoder_Direction

0x34EA 0x00

On/Off

On/Off

Off

[PCF]

Changes the motor encoder's effective direction of rotation.

The encoder provides data used to calculate motor position and

speed. This parameter must be set such that when the motor is

turning forward the controller reports a positive motor speed.

Positive motor speed must be in the forward direction in order for

the emergency reverse feature to operate properly.

Changing this parameter always results in a Parameter Change Fault

(fault code 49). Clear it by cycling the keyswitch (KSI cycle). The

Parameter Change Fault protects the controller and the operator.

Adjusting this parameter can be hazardous. Review the

Commissioning Chapter when setting this parameter.

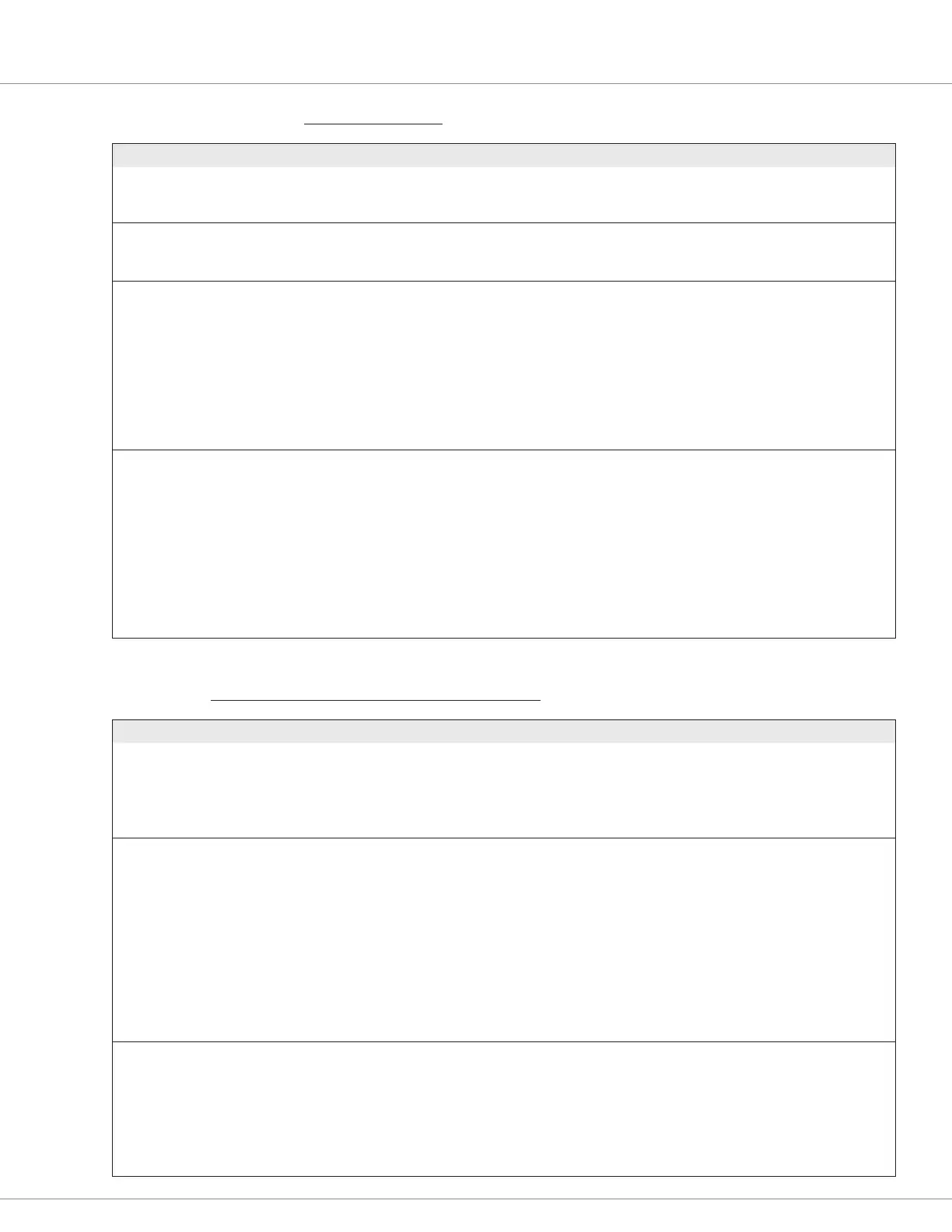

AC MOTOR SETUP/QUADRATURE ENCODER — ENCODER FAULT SETUP MENU

PARAMETER ALLOWABLE RANGE DEFAULT DESCRIPTION

Fault Detection Enable

Encoder_Fault_Detection_

Enable

0x34E3 0x00

On/Off

On/Off

On Setting this parameter to On enables the encoder fault

checking. The three fault conditions checked are:

Encoder Fault (fault code 36).

Stall Detected (fault code 73).

Encoder Pulse Error (fault code 88).

Encoder Pulse Fault Detect

Time

Encoder_Pulse_Fault_Detect_

Time

0x34E5 0x00

0.0 – 30.0 s

0 – 94

0.5 sec Denes the minimum time it takes for the controller, while the

vehicle is in motion, to detect that the encoder and the Encoder

Steps parameter do not match. When the Encoder Steps setup is

incorrect, the motor controller cannot properly calculate the AC

motor eld orientation. The loss of eld orientation can cause the

motor to spin up toward full speed once any throttle is applied.

Applying the throttle and then releasing it, while the drive current

is signicant and the motor is still accelerating, sets this timer.

Note that the motor can spin to high rpms for several seconds

before conditions allow the controller to detect a fault.

The Encoder Pulse Error (fault code 88) is set when this fault occurs.

Setting the parameter to zero will disable this fault detection.

Fault Stall Time

Enc_Fault_Stall_Time

0x34E2 0x00

0 – 10 s

0 – 5000

5 sec When the controller detects no motor encoder movements (no

pulses), it sets this timer. If no motor encoder movement is

detected by the end of this period, with the maximum throttle

applied, it sets the Stall Detected fault (fault code 73).

For example, when driving up a ramp and the vehicle ‘stalls’

because it is under-powered or over loaded (driver applying full

throttle), or if driven into an immovable object, these types of

conditions will set this fault.

Loading...

Loading...