6 — COMMISSIONING

Curtis AC F4-A Motor Controller – August 2020 Return to TOC

pg. 136

the opposite of these parameters’ default settings. e broken wire protection is by the controller

sensing the current ow from the pot wiper input (pin 16) through the potentiometer and into I/O

Ground (pin 7). If either connection opens, it triggers the rottle Input fault (ash code 4-2).

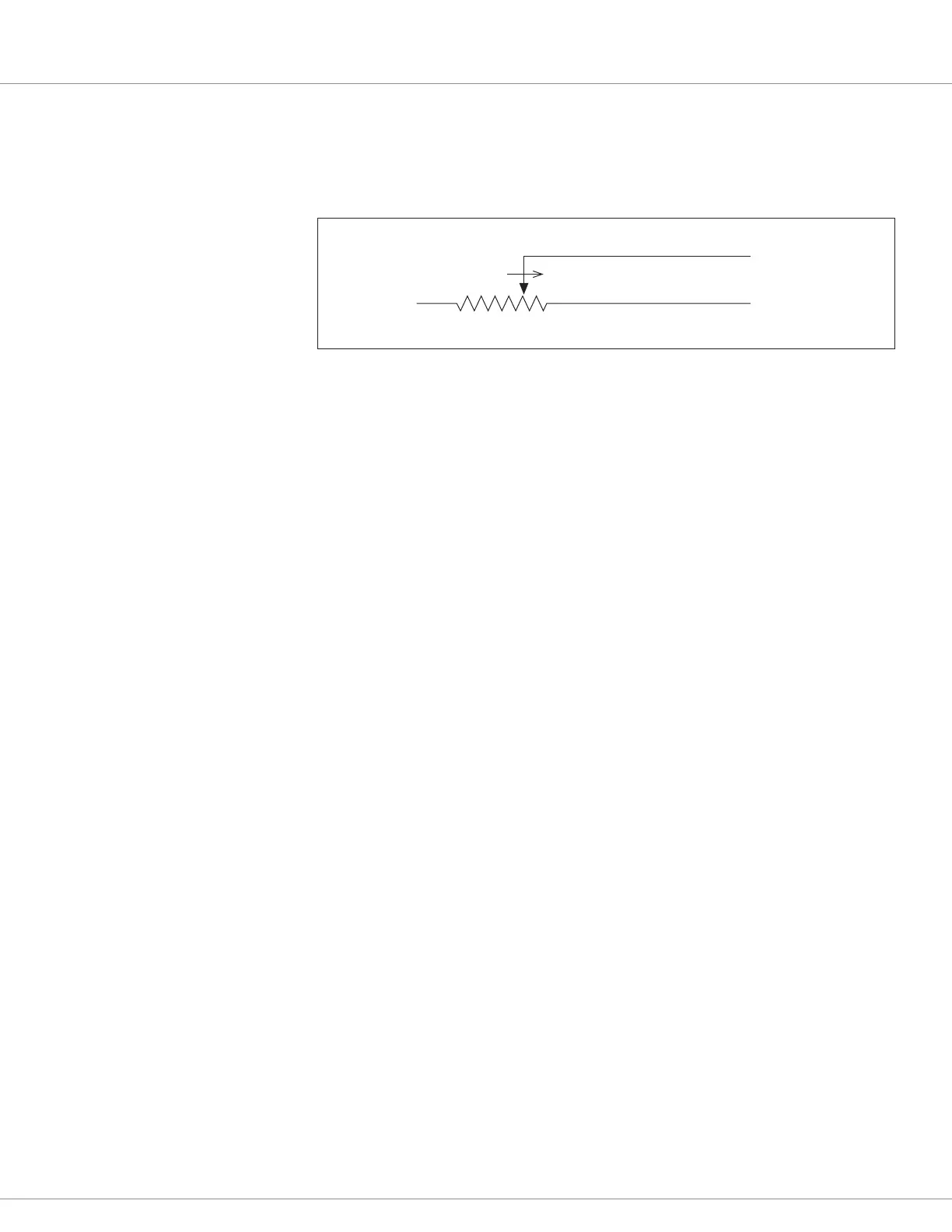

3-Wire or 2-Wire throttle parameter setup

Wire the throttle corresponding by type as illustrated in Figures 6, 25 or 26. For potentiometer

throttles, the potentiometer percentage (rottle Input) variable represents the throttle position as a

percentage of full throttle (100%). For throttle assemblies with validation switches or similar signals,

wire and program the validation signal(s) as per their type using the controller’s available switch or

analog inputs. Reference Figure 6 and Tables 5 and 6 for these available switch and analog inputs.

Be sure to include these additional signals in a VCL program as the means to integrate such throttle

validation signals into the controller application.

Note: when selecting a resistive throttle, the monitor item Analog 1 (analog_input_volts_1) reading at

pin 16 relates to the assigned potentiometer value and resistive validation, and as such, the indicated

voltage has no relevance to the throttle’s setup or diagnostics. e analog voltage monitor value will

cycle with the internal validation. Do not use the analog voltage for control purposes.

Voltage Throttle

When using a voltage source as a throttle, it is the responsibility of the OEM to provide appropriate

throttle fault detection. For ground-referenced 0–5 V throttles, the controller will detect open breaks

(i.e., wire disconnect) in the Analog1 input (analog_input_volts_1), but it cannot provide full throttle

fault (valid throttle signal) protection. For tiller-handles providing a voltage signal, throttle validation

is the responsibility of the vehicle OEM. For tiller-handles providing a CANbus throttle command (i.e.,

VCL_rottle), throttle validation is the responsibility of the vehicle OEM. It is recommended that

throttle validation be handled within the tiller-handle itself (i.e., as throttle assemblies oer).

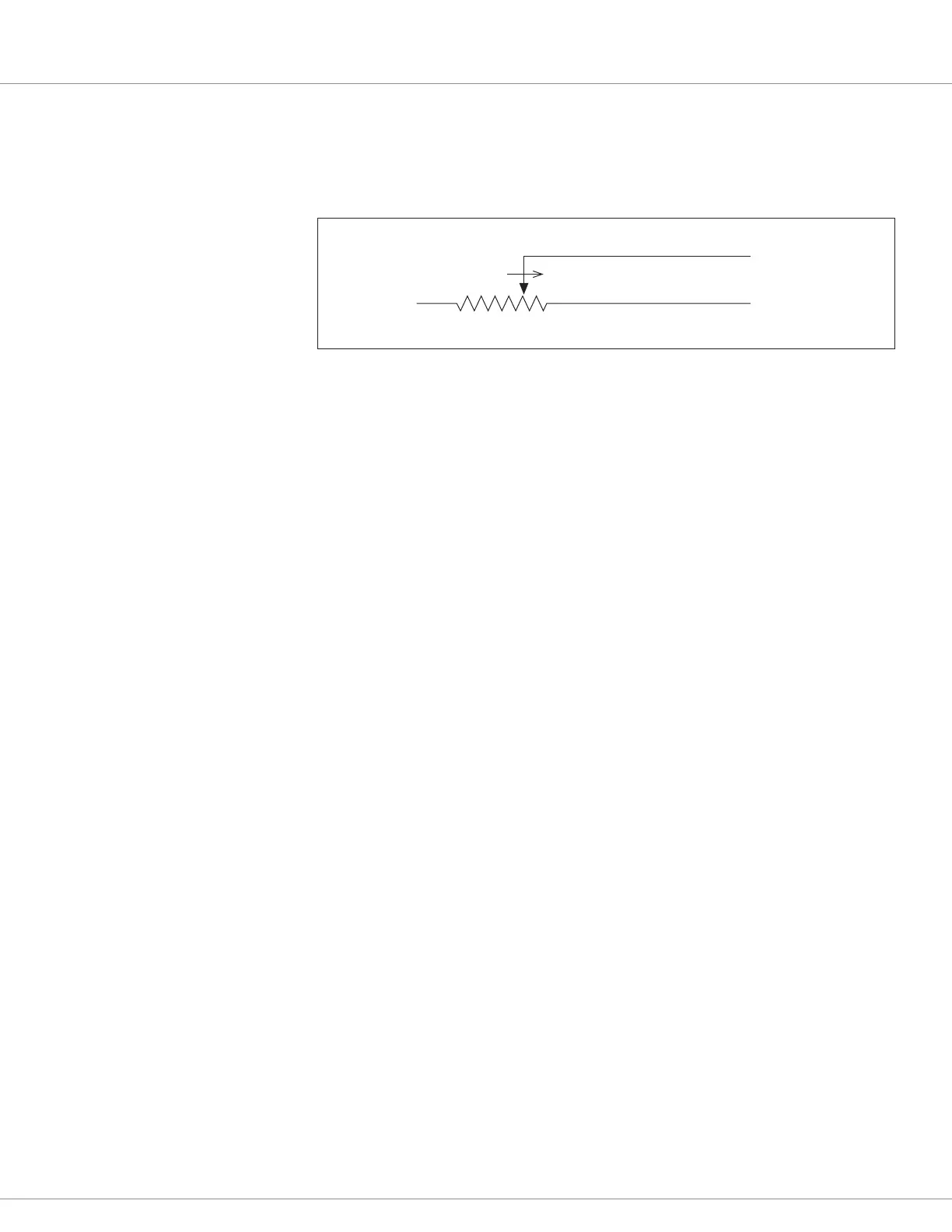

To use a current source as a voltage throttle, add a resistor in parallel to the circuit to convert the

current source value to a voltage. Size the resistor to provide a 0–5 V or 0–10 V signal variation over

the full current range. It is the responsibility of the OEM to provide appropriate throttle fault detection

in these throttles as well. Reference the diagram in Figure 28, below.

I/O Ground (Pin 7)

Pot 1 Wiper input (Pin 16)

5kΩ–0

FASTER

Figure 26

Wiring for 2-Wire

Potentiometer throttles

Loading...

Loading...