4 — PROGRAMMABLE PARAMETERS

Curtis AC F4-A Motor Controller – August 2020 Return to TOC

pg. 50

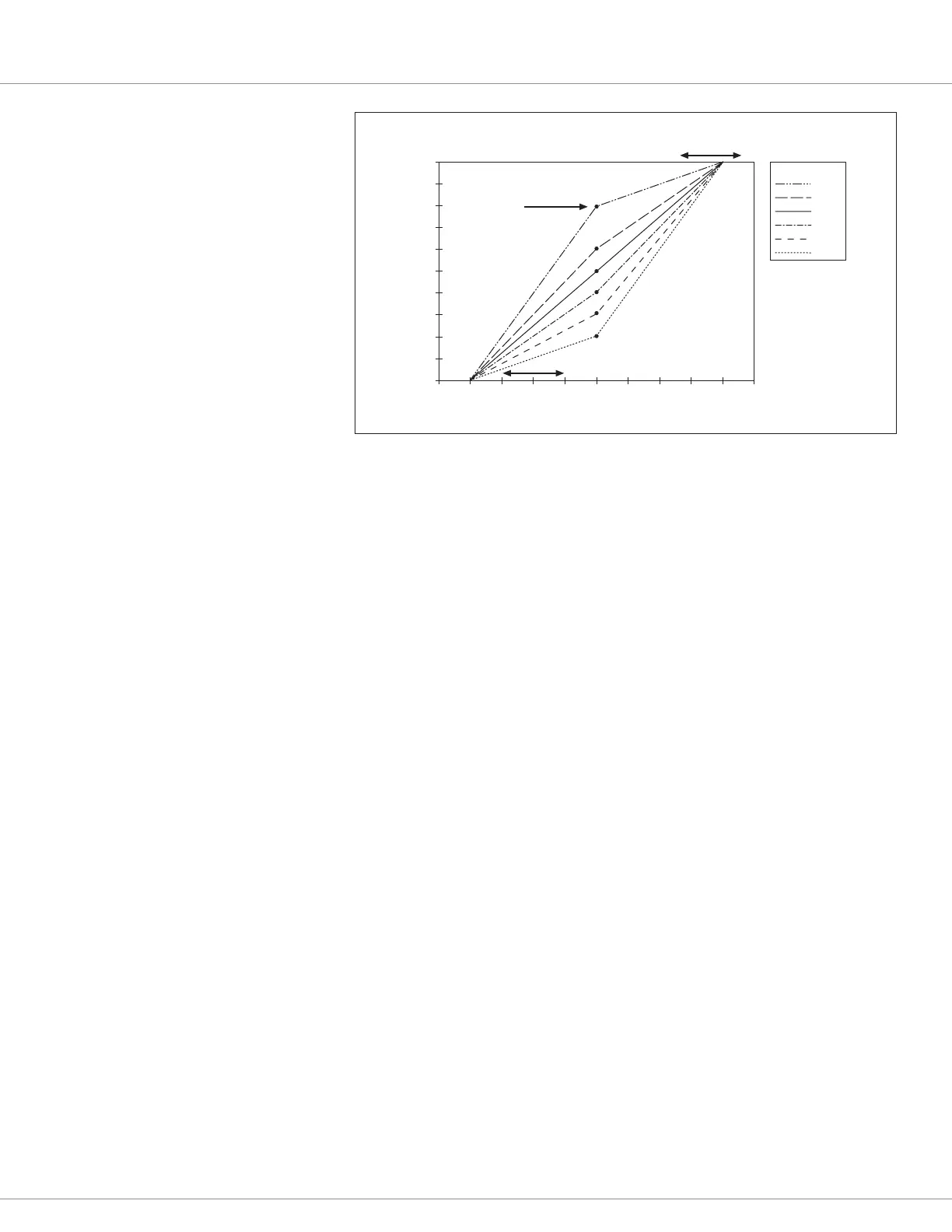

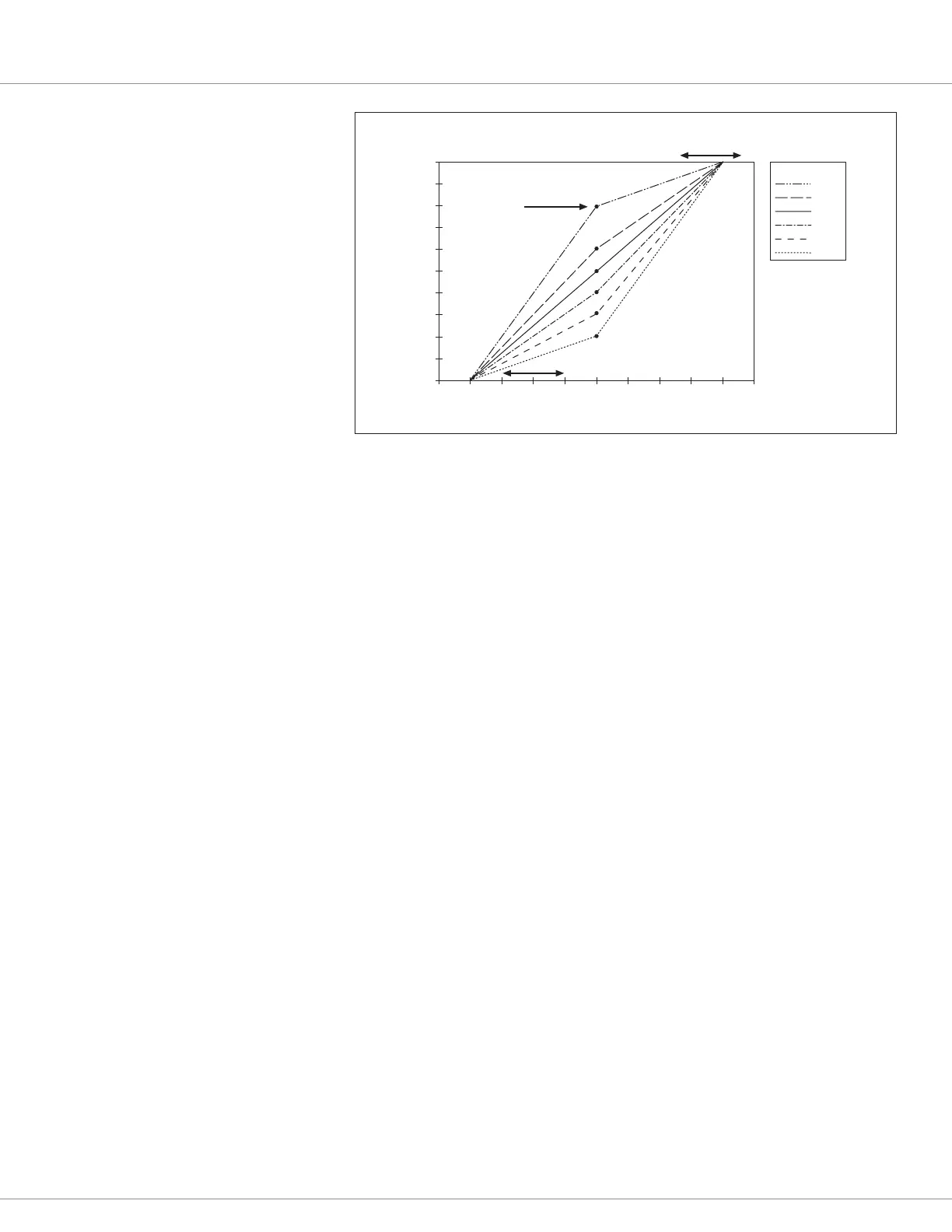

Max Input parameter

adjusts this endpoint.

80%

60%

50%

40%

30%

20%

MAP

THROTTLE INPUT PERCENT (%)

C ONTR OLL E R OUTPU T (percent)

Map Shape parameter determines the “knee”

in the output; this knee is

at an 80% Map Shape setting.

Min Input parameter

adjusts this endpoint (deadband)

10080604020 0

100

90

80

70

60

50

40

30

20

10

0

Figure 10

rottle Adjustments

Diagram

e eect of throttle

adjustment parameters.

Together these parameters

determine the controller’s

response to throttle demand

(in forward or reverse)

and to brake demand, if

applicable.

In the examples shown in

this gure,

Min Input = 10 %

Max Input = 95 %

Map Shape: six examples.

Figure 11 illustrates the throttle’s signal chain where the throttle parameters are applied. In addition to

these throttle-specic parameters, refer to the Controller Setup/Inputs menu (below) for the selection

of the throttle congurations. e default physical-throttle input is via Analog 1 Type (Pot 1 Wiper,

pin 16), which is an entry point for the throttle signal in Figure 11 (signal ow is le to right). See

Figure 6, the default wiring diagram, and Chapter 6, Commissioning, for systematic throttle-option

setup instructions.

Based upon the selection in the Inputs menu (i.e., voltage or potentiometer throttle) the throttle

will use two to three of the controller’s I/Os. For 5-volt voltage throttles, the +5 V supply (pin 26)

and I/O Ground (Pin 7) are used to power the throttle, with the signal connected to Analog 1 (pin

16). Resistive 3-wire potentiometer throttles use the Pot 6 Supply (pin 15) and the I/O Ground

(pin 7) to set up the voltage-supply circuit with the potentiometer’s wiper (working as a voltage

divider) connected to the Pot 1 Wiper (pin 16). When using a 2-wire potentiometer throttle, connect

the potentiometer’s wiper to Pot 1 Wiper (pin 16) and one end to I/O Ground (pin 7). Leave the

other end/lead open, as the brake throttle in Figure 6 is a 2-wire input. When selecting these resistive

throttles, the monitor item Analog 1 (analog_input_volts_1) voltage reading at pin 16 under goes

dynamic cycles verifying the external connections. is coupled to the assigned nominal resistance

value, results in the voltage reading having no relevance to the throttle signal. e motor direction

(Direction_Source) options are via the Forward/Reverse switch inputs or by Wigwag throttle. e

Single Switch option assigns forward as the default direction, with reverse its only input (hence, single

switch). Wigwag throttles are similar to voltage throttles, except their input voltage also determines

the motor direction. In all cases, the rst feedback in the throttle’s signal chain is the rottle_Pot_

Percent variable. Notice that the controller processes these inputs as a percentage, not as a voltage

(as noted above).

VCL can interface and modify the throttle signals at several points, from the voltage or potentiometer

input at pin 16 to the nal motor controller command. Use VCL to create unique throttle commands,

adjust parameters to provide Multimode operation, or modify the throttle command based on

steering angle, mast height, load, etc.

e throttle signal chains within the controller are sophisticated and exible. Before applying VCL

to modify these chains, it is important to understand the ramications of implementing changes.

With the physical throttle’s parameters set, the rottle_Pot_Percent variable passes to the rottle

Mapping block, which re-shapes the throttle signal magnitude and direction based on the various

rottle menu parameters and the directional inputs. When other Analog inputs are used for the

Quick Links:

Fig. 6 p.10

Loading...

Loading...