2 — INSTALLATION AND WIRING

Curtis AC F4-A Motor Controller – August 2020 Return to TOC

pg. 10

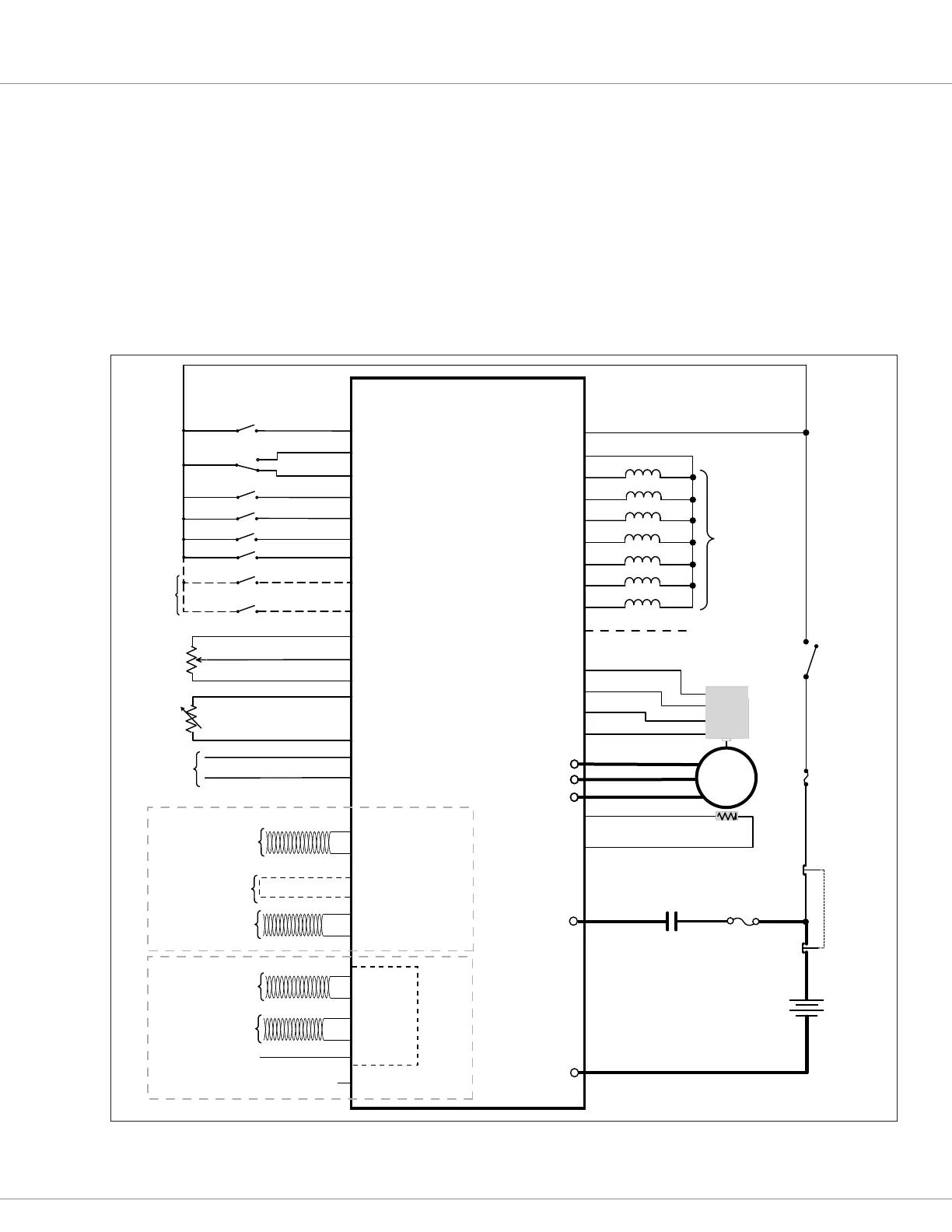

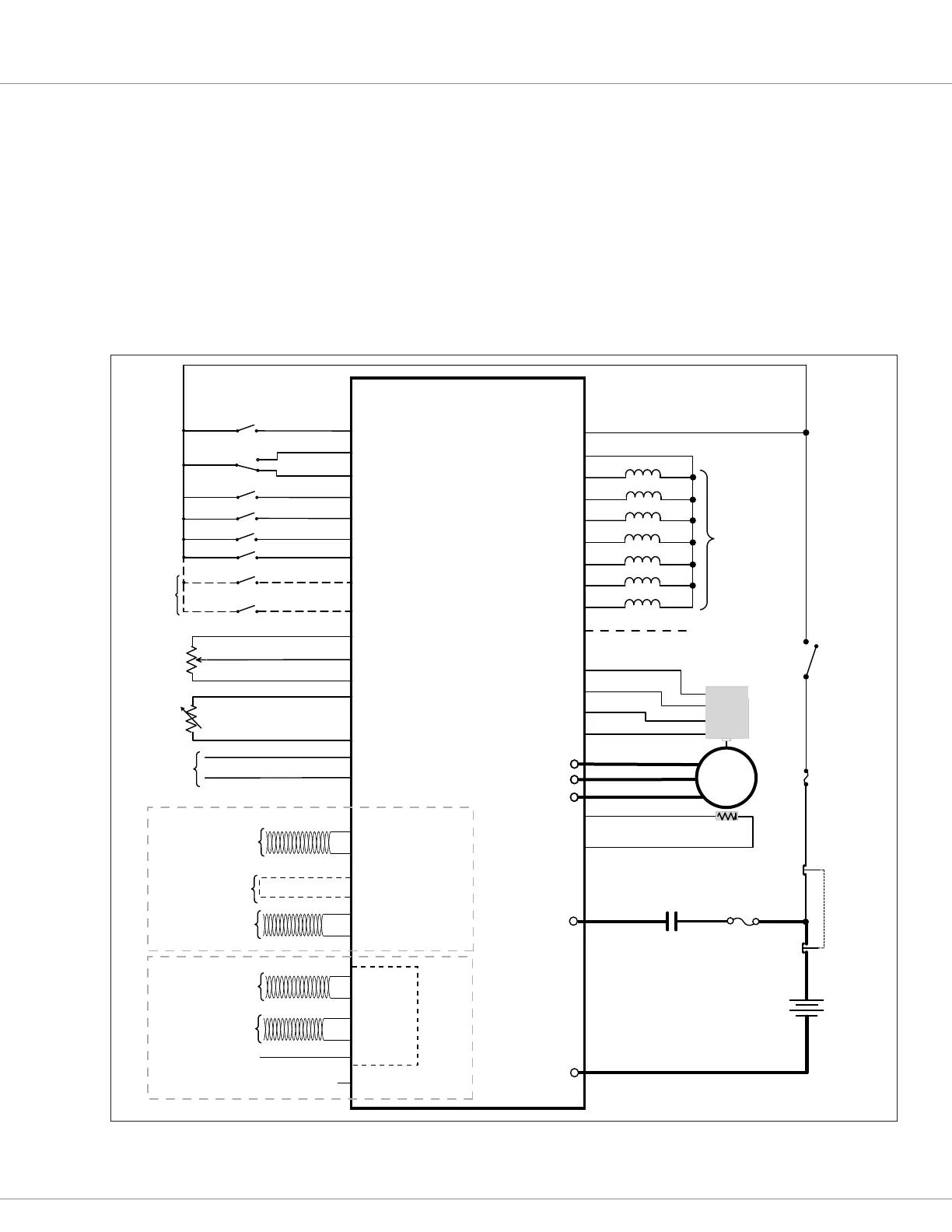

Controller Wiring Diagram (Examples)

Figure 6 illustrates the F4-A controller wiring for a Class III pallet truck using wired inputs from

switches and potentiometers, driving an induction traction motor. e Interlock, Forward, Reverse,

Li, Lower, and the redundant Emergency Reverse inputs are by external mechanical switches pulled

to KSI (B+). e traction motor feedback is a quadrature encoder and the throttle input is a 3-wire

potentiometer (which meets EEC fault protection). Beyond these assigned I/O usages, the available

(non-assigned) switch inputs, drivers, and the analog output, are programmable to suit a diverse

range of F4-A controller applications.

Figure 6 illustrates both the non-isolated and isolated CAN port options. See Appendix E for the

controller models and specications, which support these options.

Quick Links:

Appendix E p.205

NO

NC

Emergency

Reverse

Lower

Interlock

User Input

E Stop

Pole A

U

V

W

Speed/

Position

Sensor

GND

Input 2 / Motor Temp

Motor Temp

Sensor

Fuse

Load-Hold Valve

Ext. Load 2

Proportional Valve

Optional

Peripherals

Safety Disabled

and

Reverse Polarity

Protected

Loads

Input 8

Input 9

Input 7

Input 19 / Pot 19 Supply

Input 13 / Enc 2B

Input 10 (PWM)

Input 11 / Enc 1C

Input 5

Input 12 / Enc 2A

KSI

Input 31 / +5V

Input 3 / Enc 1A

Input 4 / Enc 1B

GND

Coil Supply

Driver 4 / Input 24

Driver 3 / Input 23

Driver 5 / Input 25

Driver 6 / Input 26

Driver 7 / Input 27

Driver 1 / Input 21

Driver 2 / Input 22

Driver 8

Analog Output

AC

Induction

Motor

5V

A/Sin

B/Cos

GND

18

Lift

Reverse

Forward

18

Key-Switch

Ext. Load 1

Main Coil

Ext. Load 3

EM Brake

1

26

31

32

8

10

22

9

13

Travel Limit

4

3

2

5

6

19

20

27

33

24

14

30

11

12

External

Power

Supply

Input 31 / +5V Ext Supply

Input 14 / +12V Ext Supply

26

25

Input 18 / Pot 18 Wiper

GND

Brake

Throttle

Input

7

17

Traction

Motor

Throttle

Input

Input 6 / Pot 6 Supply

Input 1 / Pot 1 Wiper

GND

7

16

15

B+

Main Contactor

Battery

-

+

Fuse

B–

EMERGENCY

STOP

E Stop

Pole B

+ –

CAN PORT #2*

CAN2 L

CAN2 H

Short for

Termination

120Ω CAN1

34

21

28

29

twisted pair, recommended

CAN PORT #1

CAN1 H

CAN1 L

23

35

twisted pair, recommended

CAN PORT #1

CAN1 H

CAN1 L

Isolated GND

23

35

34

CAN2 L

CAN PORT #2

CAN2 H

28

29

twisted pair, recommended

ISOLATED

CAN PORTS

21

Not Used

ISOLATED CAN MODELS

MODELS W/O ISOLATED

CAN

twisted pair, recommended

Figure 6

AC F4-A Basic Wiring Diagram

Loading...

Loading...