8

Curtis 1222 Manual, os 15

2 9 J A N U A R Y 2 0 1 3 D R A F T

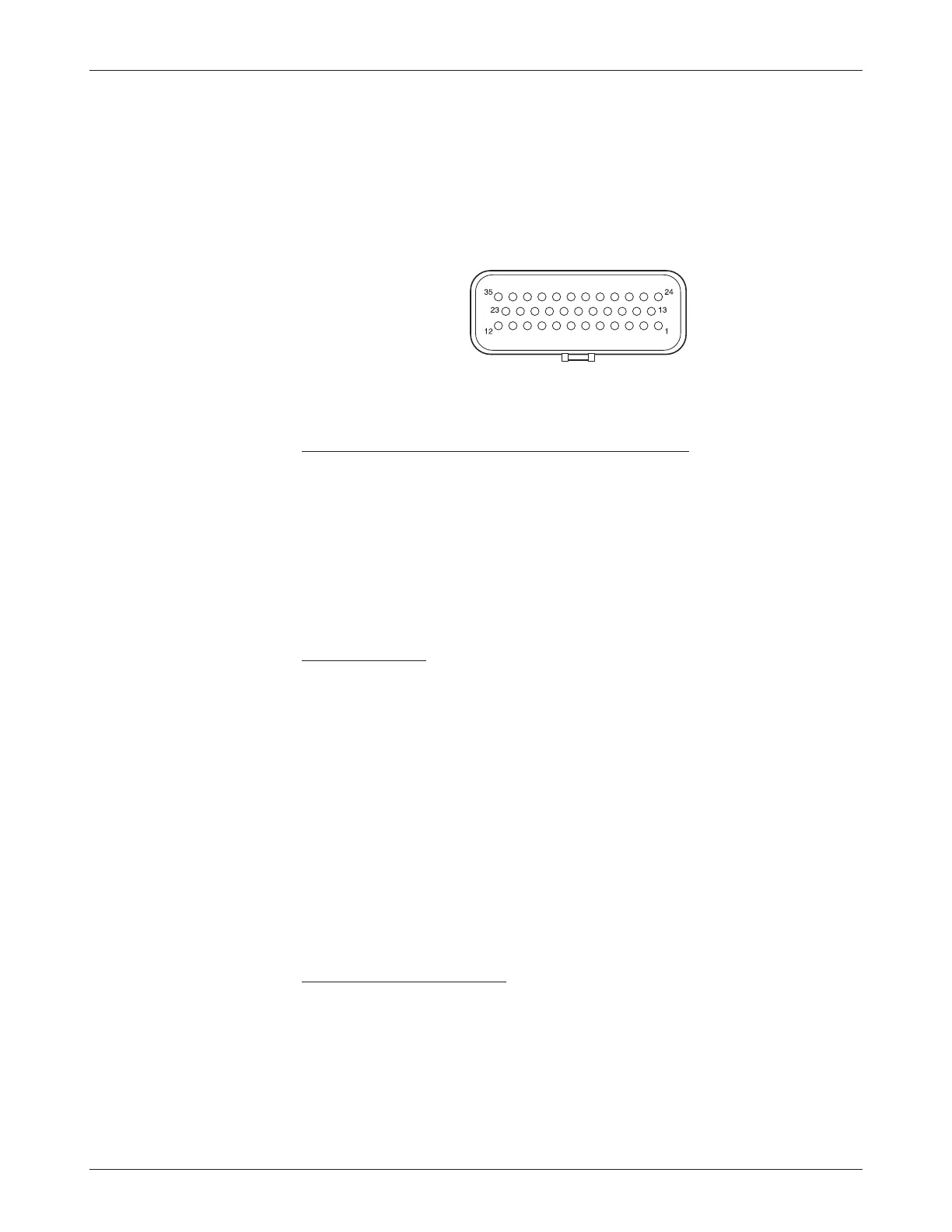

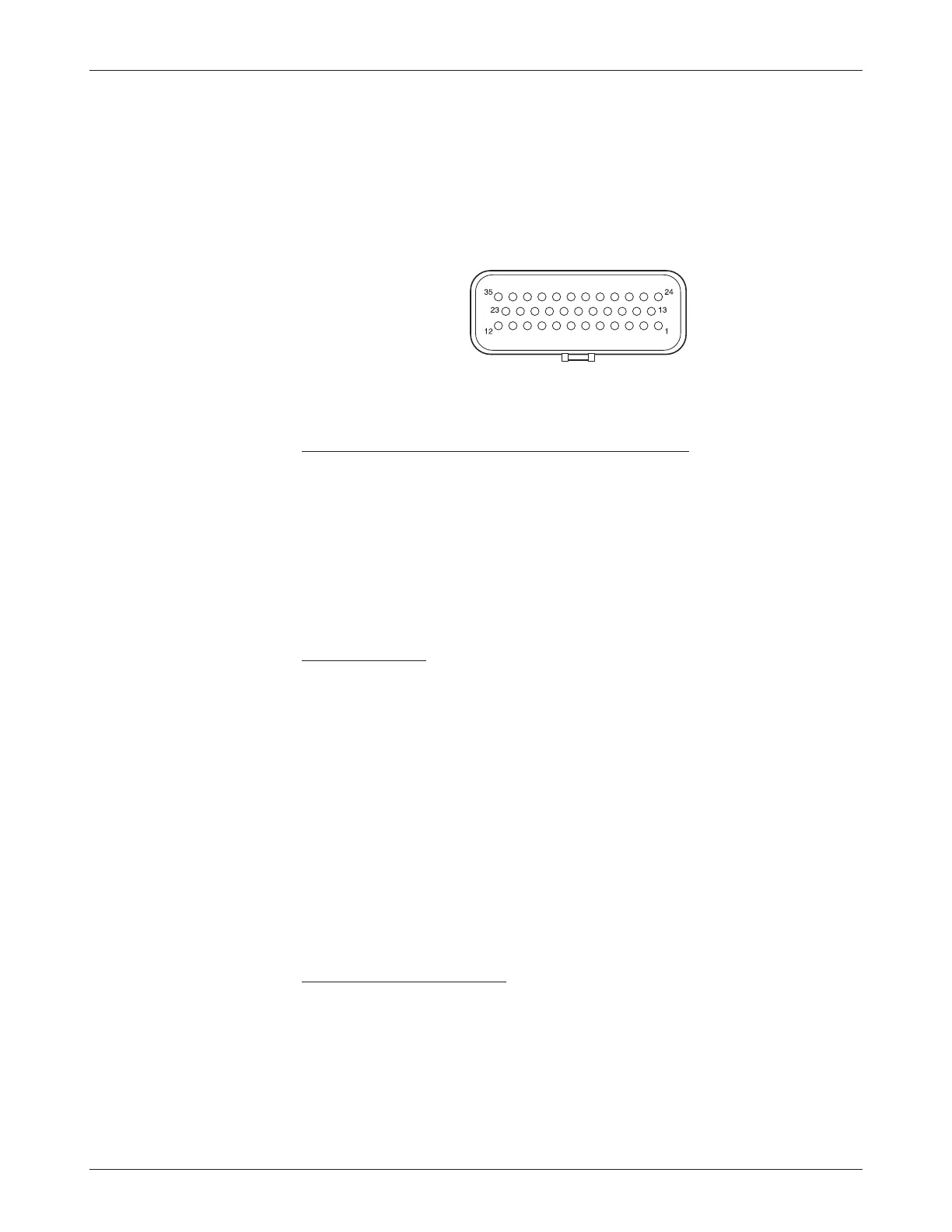

LOW CURRENT CONNECTIONS

All low power connections are made through a single 35-pin AMPSEAL con

-

nector. The mating plug housing is AMP p/n 776164-1 and the contact pins

are AMP p/n 770520-3. The connector will accept 20 to 16 AWG wire with

a 1.7 to 2.7mm diameter thin-wall insulation.

The 35 individual pins are characterized in Table 2.

2 — INSTALLATION & WIRING: Low Current Connections

J1

Low current wiring recommendations

Command input encoder and Steer motor encoder

The encoder wires should be bundled together as they run between the motor

and controller logic connector. These can often be run with the rest of the low

current wiring harness. The encoder cables should not be run near the motor

cables. In applications where this is necessary, shielded cable should be used

with the ground shield connected to the I/O ground (pin 18 or pin 30) at only

the controller side. In extreme applications, common mode filters (e.g. ferrite

beads) could be used.

CAN connection

The two CAN wires should be connected directly to the corresponding CAN

pins on the traction controller: running from pin 23 (CAN High) on the

steering controller to pin 23 (CAN High) on the traction controller, and from

pin 35 (CAN Low) on the steering controller to pin 35 (CAN Low) on the

traction controller.

Note: The 1222 controller has no internal 120

Ω CAN terminating

resistor. Typically the wiring of the CAN bus nodes is a daisy chain topology

with 120

Ω CAN terminating resistors at each end. If the vehicle wiring is done

such that the 1222 is the last node in the chain, an external 120

Ω terminating

resistor should be provided by the OEM in the wiring harness.

CAN wiring should be kept away from the high current cables and cross

it at right angles when necessary.

All other low current wiring

The remaining low current wiring should be run according to standard practices.

Running low current wiring next to the high current wiring should always be

avoided.

Loading...

Loading...