ANNEX G: SUNDRIES PAGE 69

Procedure to realize an ideal curve

In this example, an ideal curve having an internal radius of 50 mm is to be

made.

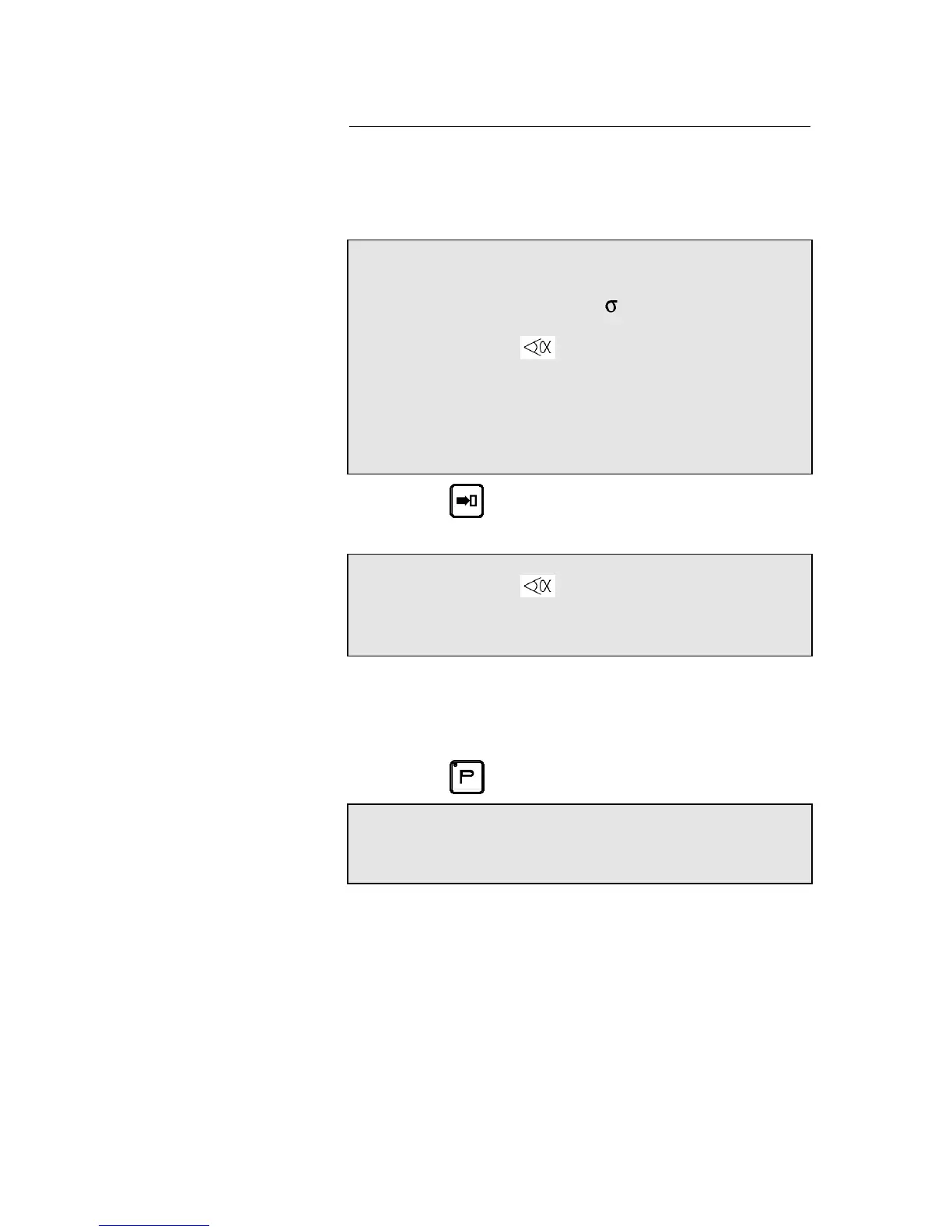

Call the PRODUCT STATUS page and fill in the fields as described

below.

P 0 P+ ___ N 1 I/mm

CODE CAL_/__.__

p/d 1/ 1 St:1 Al:_ SS:_

Th: 2.00 Kg/mm² 45.000

Lmat 2000 Dev L ___.__

-N- -L- - - -p/d- -ri- CR TOL

1 100.00 90.0°__/__ 50 00 15 ___

2 200.00 90.0°__/__ ____.__ __ ___

3 100.00 ____._°__/__ ____.__ __ ___

4 ____.__ ____._°__/__ ____.__ __ ___

5 ____.__ ____._°__/__ ____.__ __ ___

____.__ ____._°__/__ ____.__ __ ___

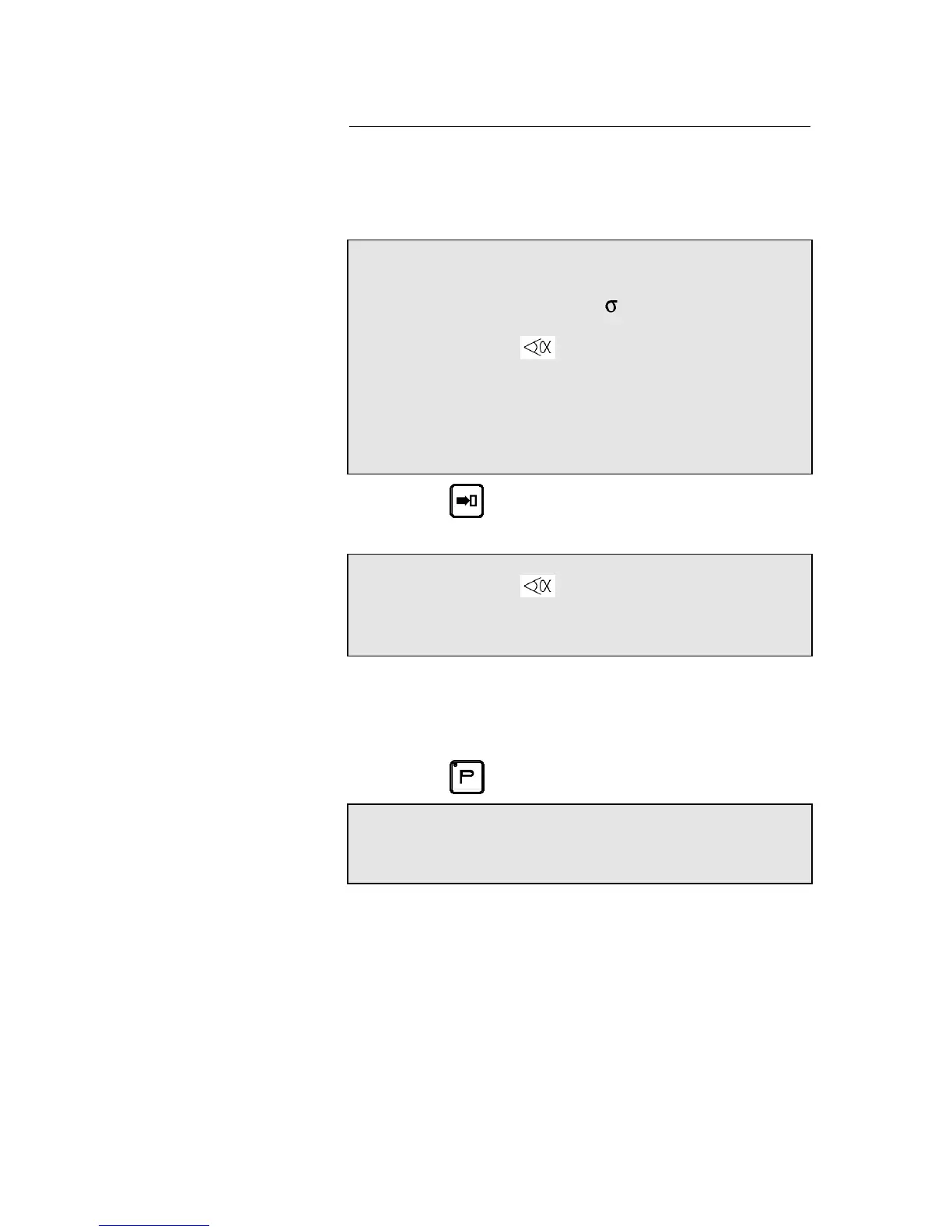

Press the key.

The system fills in the Dev L, ri and TOL fields.

Lmat 2000 Dev L 372.79

-N- -L- - - -p/d- -ri- CR TOL

1 100.00 90.0° 1/ 1 50 00 15 0

2 200.00 90.0° 1/ 1 2.13 __ ___

3 100.00 ____._°__/__ ____.__ __ ___

The number 15 gives a good approximation, as the tolerance, that is the dif-

ference between the apex of the chord and the theoretical radius, is 0 mm.

The calculated values vary in function of the thickness, the V opening of the

die, etc.

Press the

key and fill in the LEG and FACE fields as below.

P 0 N 1 p/d 1/ 1

N FACE LEG CR p/d

1 1 0 15 1/ 1

2 2 1 __ 1/ 1

Attention The X MEM values on the sequence page do not correspond to the position

actually aimed for by the axis during ideal curve.

Loading...

Loading...