Electrical installation, control cables

Torque: 0.5-0.6 Nm

Screw size: M3

Generally speaking, control cables must be screened/

armoured and the screen must be connected by

means of a cable clamp at both ends to the metal cab-

inet of the unit (see Earthing of screened/ armoured

control cables). Normally, the screen must also be con-

nected to the body of the controlling unit (follow the

instructions for installation given for the unit in ques-

tion).

If very long control cables are used, 50/60 Hz earth

loops may occur that will disturb the whole system.

This problem can be solved by connecting one end of

the screen to earth via a 100nF condenser (keeping

leads short).

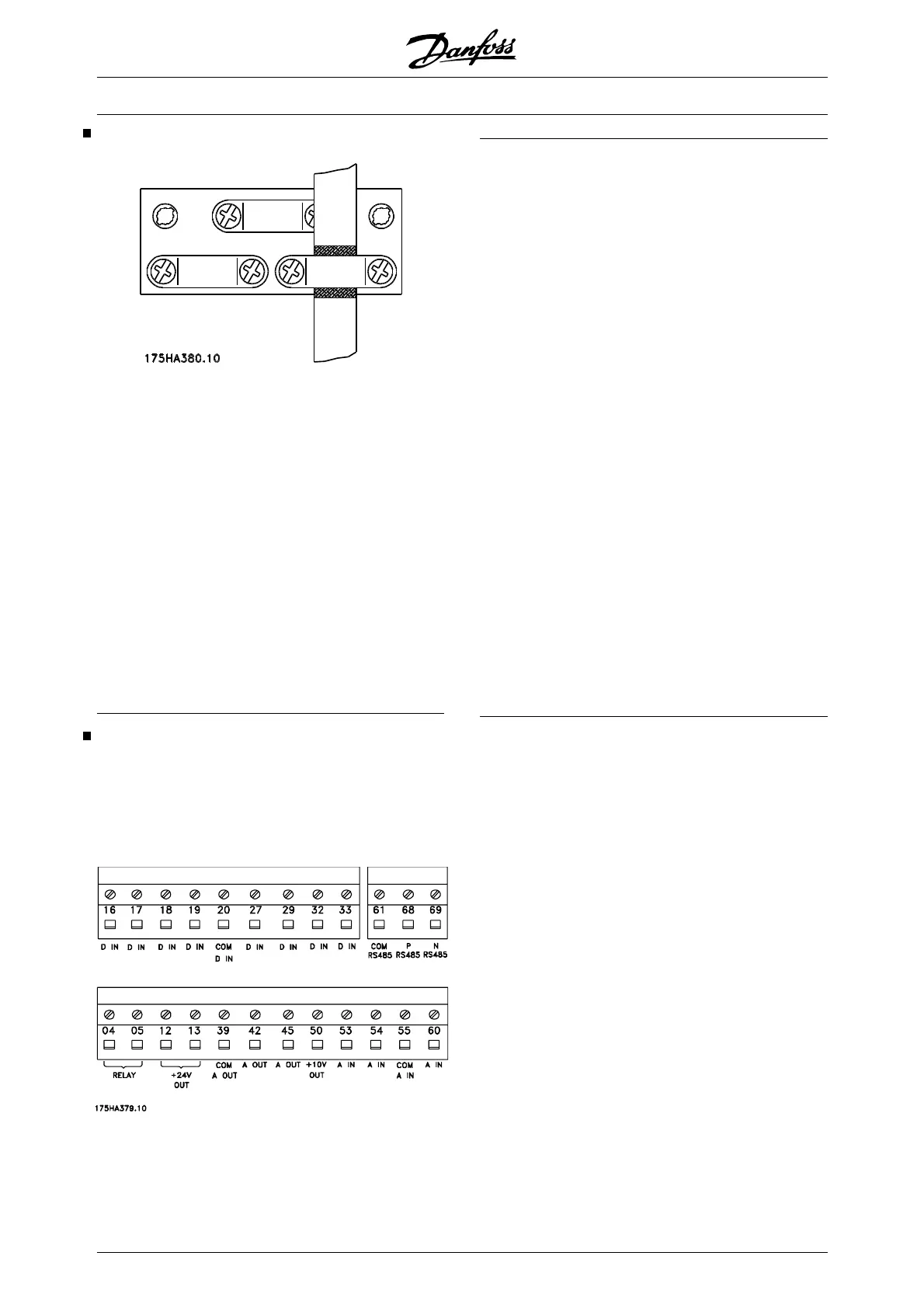

Electrical installation, control cables

Max. control cable cross section: 1.5 mm

2

/16 AWG

Torque: 0.5-0.6 Nm

Screw size: M3

See Earthing of screened/armoured control cables for

correct termination of control cables.

No. Function

04, 05 Relay output 2 can be used for indicating sta-

tus and warnings.

12, 13 Voltage supply to digital inputs. For the 24 V

DC to be used for digital inputs, switch 4 on the

control card must be closed, position "on".

16-33

Digital inputs. See parameters 300-307 Digital

inputs.

20 Ground for digital inputs.

39 Ground for analogue/digital outputs. Must be

connnected to terminal 55 by means of a three-

wire transmitter. See Examples of connection.

42, 45 Analogue/digital outputs for indicating frequen-

cy, reference, current and torque. See param-

eters 319-322 Analogue/digital outputs.

50 Supply voltage to potentiometer and thermis-

tor 10 V DC.

53, 54 Analogue voltage input, 0 - 10 V DC.

55 Ground for analogue voltage inputs.

60 Analogue current input 0/4-20 mA. See pa-

rameters 314-316 Terminal 60.

61

Termination of serial communication. See

Earthing of screened/armoured control cables.

This terminal is not normally to be used.

68, 69 RS 485 interface, serial communication.

Where the frequency converter is connected to

a bus, switches 2 and 3 (switches 1- 4 - see

next page) must be closed on the first and the

last frequency converter. On the remaining fre-

quency converters, switches 2 and 3 must be

open. The factory setting is closed (position

on).

VLT

®

6000 HVAC Series

88 MG.61.B5.02 - VLT

®

is a registered Danfoss trademark

Loading...

Loading...