A partial load must be suspended from the load hook when measuring the chain for wear or deformation. This

measurement can be taken in two different ways.

1. Measuring with a calliper gauge

2. Measuring with a chain gauge

Wear of individual link

Fig. 47

The chain link contact areas must be visually checked for traces of wear. If the chain hangs at angle while it is

unloaded, for example, this usually indicates wear of an individual chain link.

Measure the wire diameter of the chain in the chain link contact area by means of a calliper gauge, as required. Min.

values of the wire diameter see⇒ "Tab. 53", Page 80.

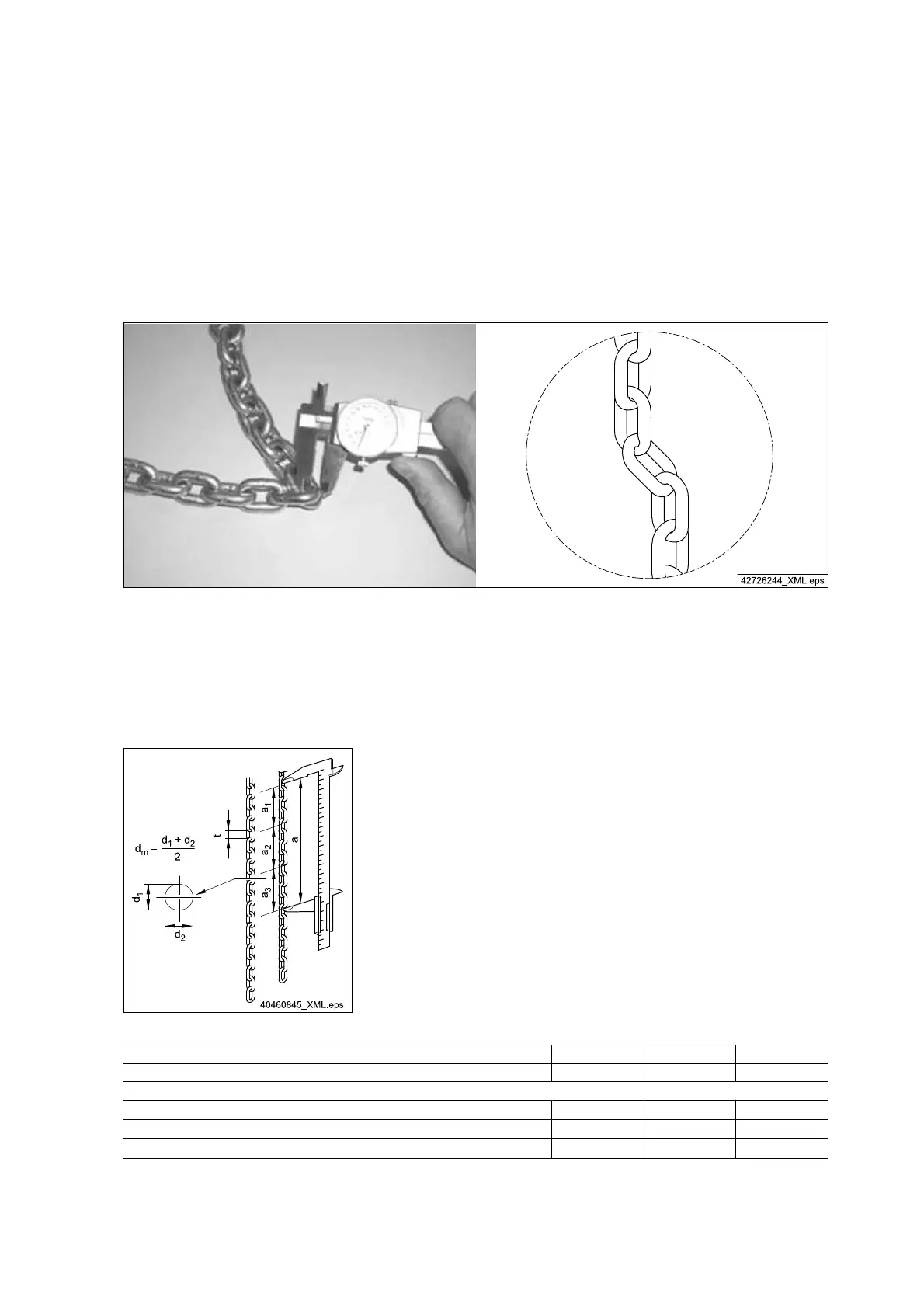

Measuring with a calliper gauge

Fig. 48

Measurements on 11 chain links may be taken in steps of 2 x 3 and 1 x

5 chain links.

The sum total of the 3 readings taken, i.e. a

1

+ a

2

+ a

3

must not exceed

limit a. Otherwise the chain must be replaced.

Demag is stamped on every 12th link of genuine Demag chains.

Do you find that, on fitting a new chain, it does not run smoothly over the

sprocket? Please contact our after-sales service centre.

We urgently recommend you use genuine Demag parts. This will ensure

that the safety and service life of the chain hoist is guaranteed.

Demag chain hoist DC Com 1/2 DC-Com 5 DC-Com 10

Chain designation d x t 4.2 x 12.2 5.3 x 15.2 7,4 x 21,2

Limit dimensions according to DIN 685 part 5

Measurement over 11 chain links outside, max. dimension = a

1

+ a

2

+ a

3

144.7 mm 180.3 mm 253 mm

Overall length of 1 chain link measured on the inside, max. dimension t 12.8 mm 15.9 mm 22.4 mm

Measurement of the chain link diameter, min. dimension d

m

= 0,9 x d

3.8 mm 4.8 mm 6.7 mm

Tab. 53

80

21480244/181209

Loading...

Loading...