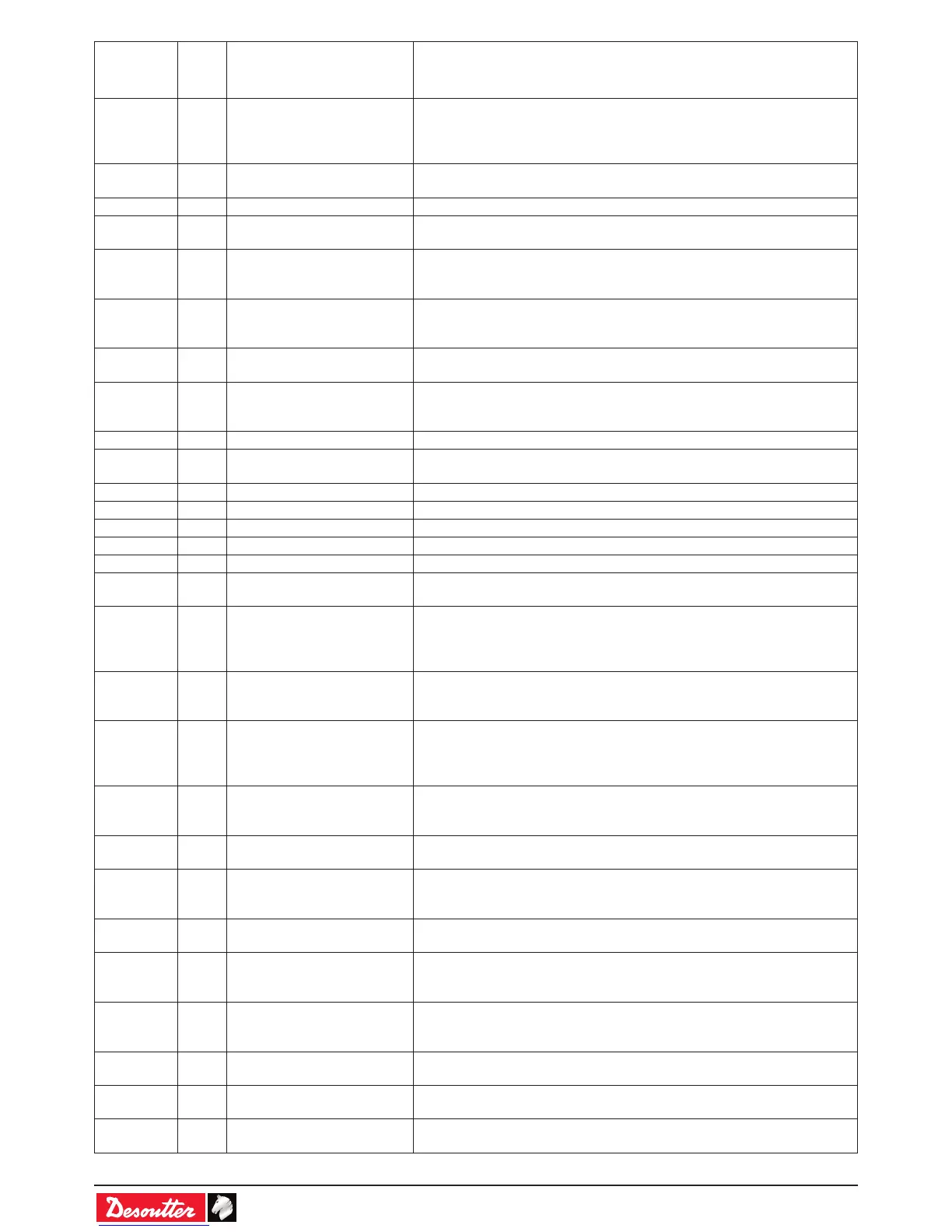

Appendix - User info codes _02/2017- 32 -

Type of

code

Code

no.

Description Resolution procedure

Warning 41 Unauthorized tool 1- The tool connected to the controller is not authorized.

2 Maximum number of battery tool reached or tightening unit associated

doesn't exist anymore

3- Check the ePOD connection and capacity.

Warning 62 Overload of torque 1- Overload of the torque, could be a rehit

2- Check tool cable is not damaged

Warning 201 Replace RTC battery 1- The real time clock backup battery needs to be replaced.

Warning 212 Result not stored 1- It was not possible to persist the tightening result in the controller

2- Contact your Desoutter representative for support

Warning 214 Short circuit 1- Serial peripheral default.

2- Disconnect and reconnect.

3- Check the serial peripheral.

Warning 246 Synchro I/O problem 1- Error detected on synchronisation input

2- Check the conguration of I/O

3- Check the synchronisation cable

Warning 250 Pset corrupted 1- Pset is not dened correctly

2- Check the Pset

Warning 253 Incorrect tool Id 1- Pset is not dened correctly.

2- One tool declared in the Pset is not part of the tightening unit

3- Check the Pset.

Warning 257 Remote start error 1- Verify the tool trigger is correctly pushed

Warning 258 Calibration need Pset mode 1- For tool calibration, the Tightening Unit has to be in Pset mode

2- Change the Tightening Unit mode into Pset mode.

Warning 267 Result transfer error Result transfer error

Warning 273 Debug UsrInfo 1- This UsrInfo is for debug. Contact dev team.

Warning 501 CVILogix user info Message generated by CVILOGIX program

Warning 600 Controller disconnected DCT_MOT_CONTROLLER_DISCONNECTED_PROCEDURE

Warning 601 RESULT NOT OK Result not OK

Error 6 Rotor locked 1-Unable to start tool motor (rotor is locked), change your tool

2-Contact your Desoutter representative for support

Error 7 Motor too hot 1- Tool is locked because its maximum motor temperature has been

reached.

2- Tool will remain locked until the motor temperature comes back to its

normal value.

Error 8 Tool angle fault 1- Problem detected with the tool angle sensor

2- The tool needs maintenance.

3- Contact your Desoutter representative for support

Error 9 Tool invalid param 1- Please check the tool compatiblity.

2- The tool memory cannot be read or is invalid.

3- The tool needs maintenance. If the problem occurs again, contact your

Desoutter representative for support.

Error 12 Tool EEPROM error 1- The tool memory cannot be read or is invalid.

2- The tool needs maintenance. If the problem occurs again, contact your

Desoutter representative for support.

Error 13 Bad tool ground 1- Phase-phase or phase to ground shortcircuit.

2- Disconnect the tool. Contact your Desoutter representative for support.

Error 14 Tq. power default 1- The torque sensor is not corrrectly supplied

2- The tool needs maintenance. If the problem occurs again, contact your

Desoutter representative for support.

Error 18 Torque out of range ! 1- The target torque value is above the tool max. torque.

2- Check Pset settings against tool characteristics.

Error 19 Tool comm. error 1- Tool communication error.

2- Check tool and cable connections. If the problem occurs again, contact

your Desoutter representative for support.

Error 20 Tool LED err. 1-Tool LED are not corrrectly supplied

2- Disconnect and reconnect the tool. If the problem occurs again, contact

your Desoutter representative for support.

Error 23 Unsupported tool 1- The tool connected to the controller is not supported.

2- Contact your Desoutter representative for more information.

Error 29 The battery is empty 1- The battery is discharged. The tool cannot tighten.

2- Recharge the battery.

Error 31 Battery error 1- Abnormal battery voltage, the tool cannot tighten.

2- Recharge the battery. If the problem occurs again, replace the battery.

Loading...

Loading...