DINO 240RXT

44

17.7 REGULAR SERVICING

The lift shall be serviced regularly at intervals of 11 - 12 month.

Under demanding conditions where moist, corrosive substances or corrosive climate may speed up the

deterioration of the structure and induce malfunctions, the inspection must be performed more often and

the influence of corrosion and malfunctions must be reduced by using appropriate protective means.

Only technical specialists who are familiar with the structure and the operation of the lift are allowed to

maintain the lift.

We recommend turning to the service staff of the dealer.

SCHEDULE FOR REGULAR SERVICING

1. Clean the lift thoroughly before the service

The hydraulic and electric appliances must not be dismantled if they are not clean. Any contaminants in

the system may cause malfunctions later on. Wash the lift externally.

NOTE! Be careful not to direct the high pressure water jet straight to the electric appliances, such as the

control panels on the chassis and on the platform, relays, solenoid valves and limit switches.

- use pressure air to dry the electric devices, hydraulic connectors etc.before opening them

- apply appropriate moisture repellent to the electric appliances after the drying

- always protect the piston rods with e.g. CRC3-36 anti-corrosive agent after washing with a

solvent

REMEMBER CLEANLINESS!

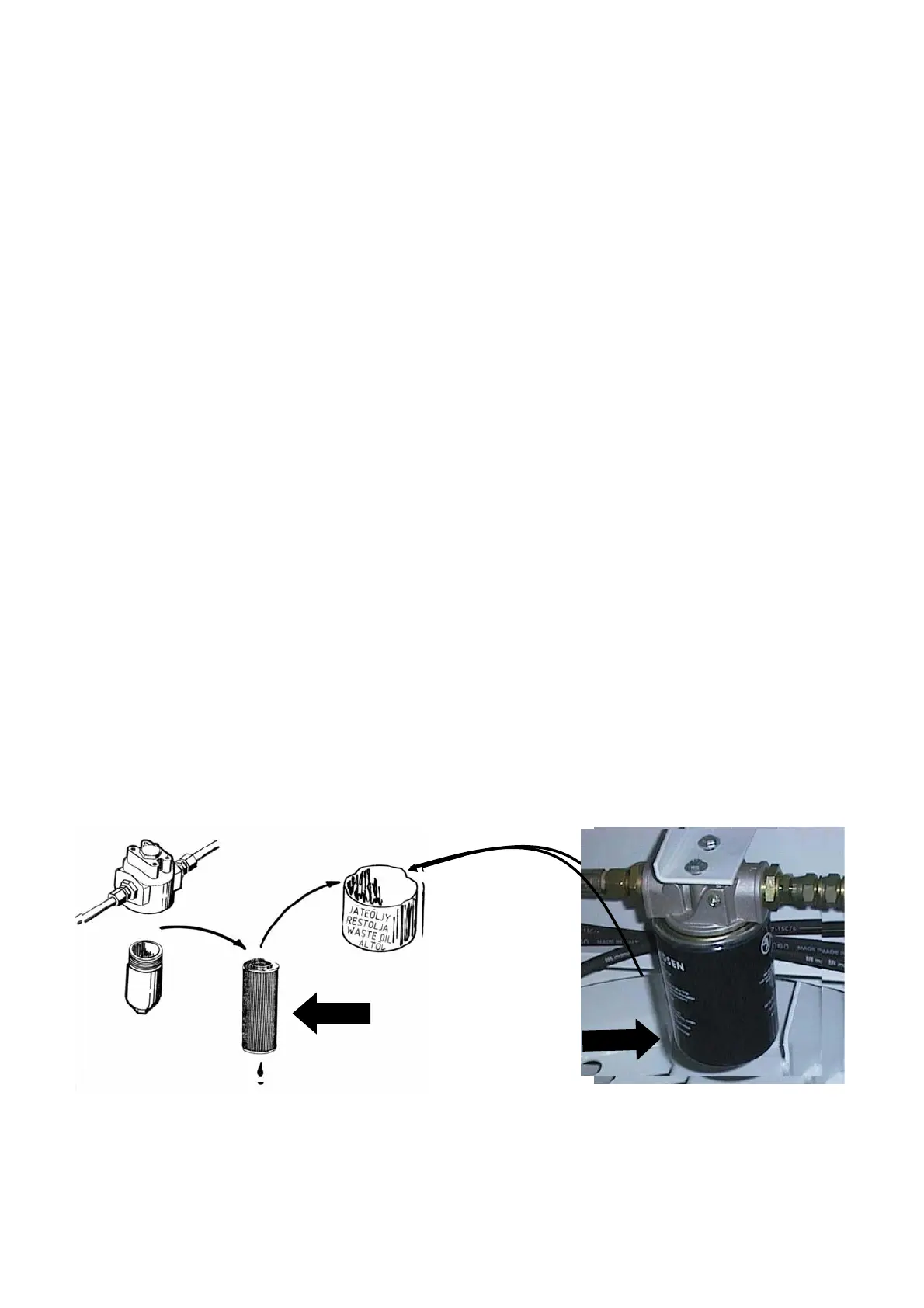

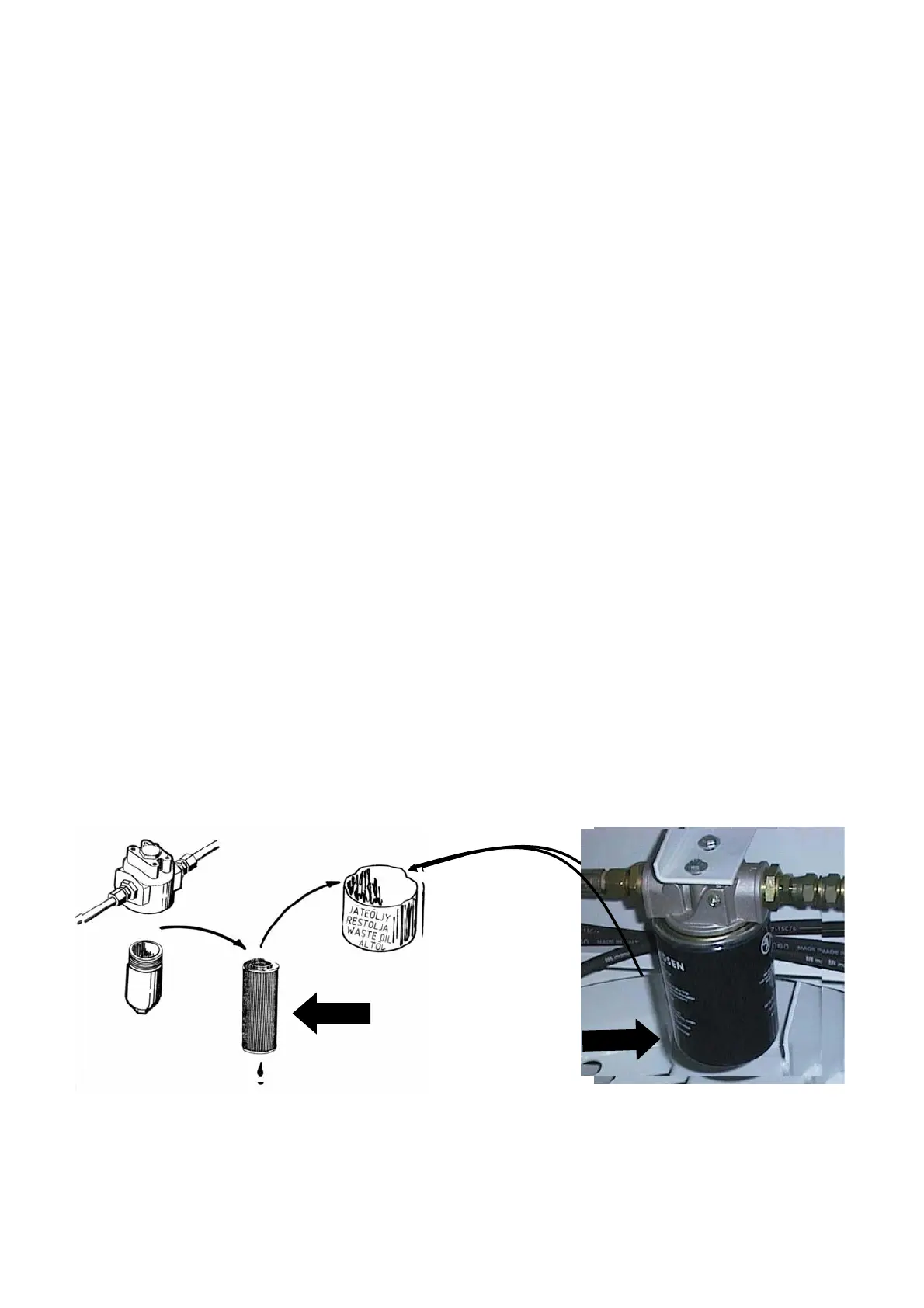

2. Change the hydraulic oil and replace the filter

(protect your skin against the hydraulic oil)

- drain the oil tank through the draining plug opening, with all cylinders in retracted position

- clean and rinse the oil tank with suitable agent

- replace the pressure and return filters

- install the drain plug

- refill the tank with fresh oil, the oil volume required for change is about 50 l

.

- Factory filling:Mobil EAL Hydraulic Oil 32. Material Safety Sheet: 581017-60

The viscosity class of the hydraulic oil must be ISO VG 32 and the oil must meet the

requirements according to DIN 51524- HLP.

- never mix different oil sorts

Loading...

Loading...