DINO 240RXT

45

- if required, top up hydraulic oil to the level with the upper edge of the level eye while the lift is

in the transport position.

.

3. Check the hydraulic hoses and pipes

Replace any externally damaged hoses or clashed pipes. Check the connections.

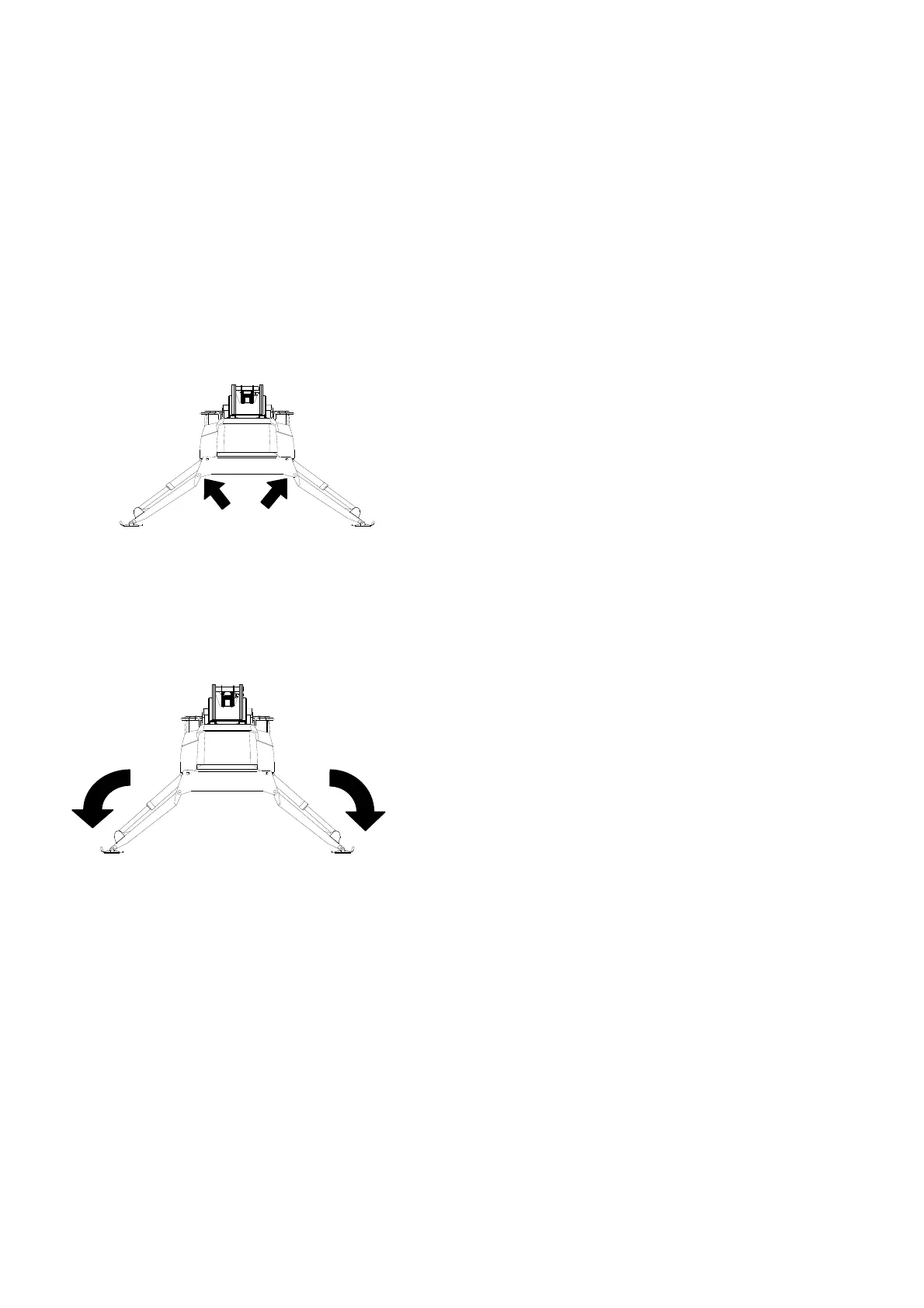

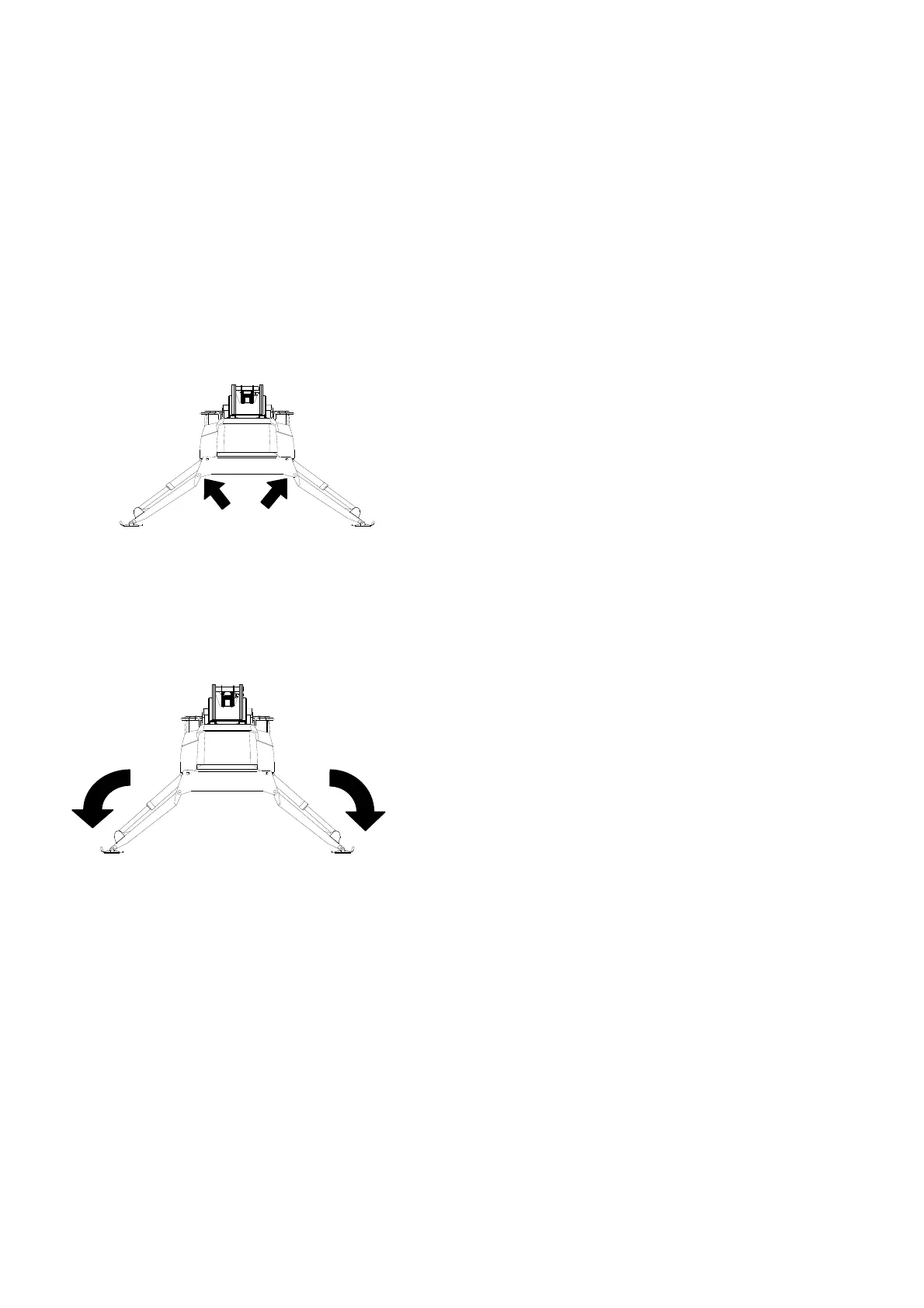

4. Inspect joints of the support outrigger

- lower the outriggers slightly

- swing the outriggers back and forth in the horizontal plane and check the joints for play

- check the operation and condition of the limit switch mechanisms on the outriggers

- replace any worn out parts

- lubricate the joints (refer to the lubrication plan)

Lower the outriggers to support position.

5. Inspect the cylinders, and lubricate the joint bearings (refer to the lubrication plan).

- drive the lift cylinder to its upper position from the chassis control panel and inspect the condition of

the piston rod and tightness of the connections

- drive the lift cylinder to its lower position from the chassis control panel and inspect the connections

for tightness

- retract and extend the telescope cylinder from the chassis control panel and inspect the condition and

tightness of the cylinder

- lubricate the joints of the lifting, telescope and levelling cylinders

- extend the articulated arm cylinders from the lower control panel and inspect their condition and

tightness

- inspect the outrigger cylinders and lubricate their joints

Loading...

Loading...