SuperSigma2 QRM PMS – V01.02.02 17-1-2020 Page 43 (58) ©2019 DMC GmbH Herten Germany

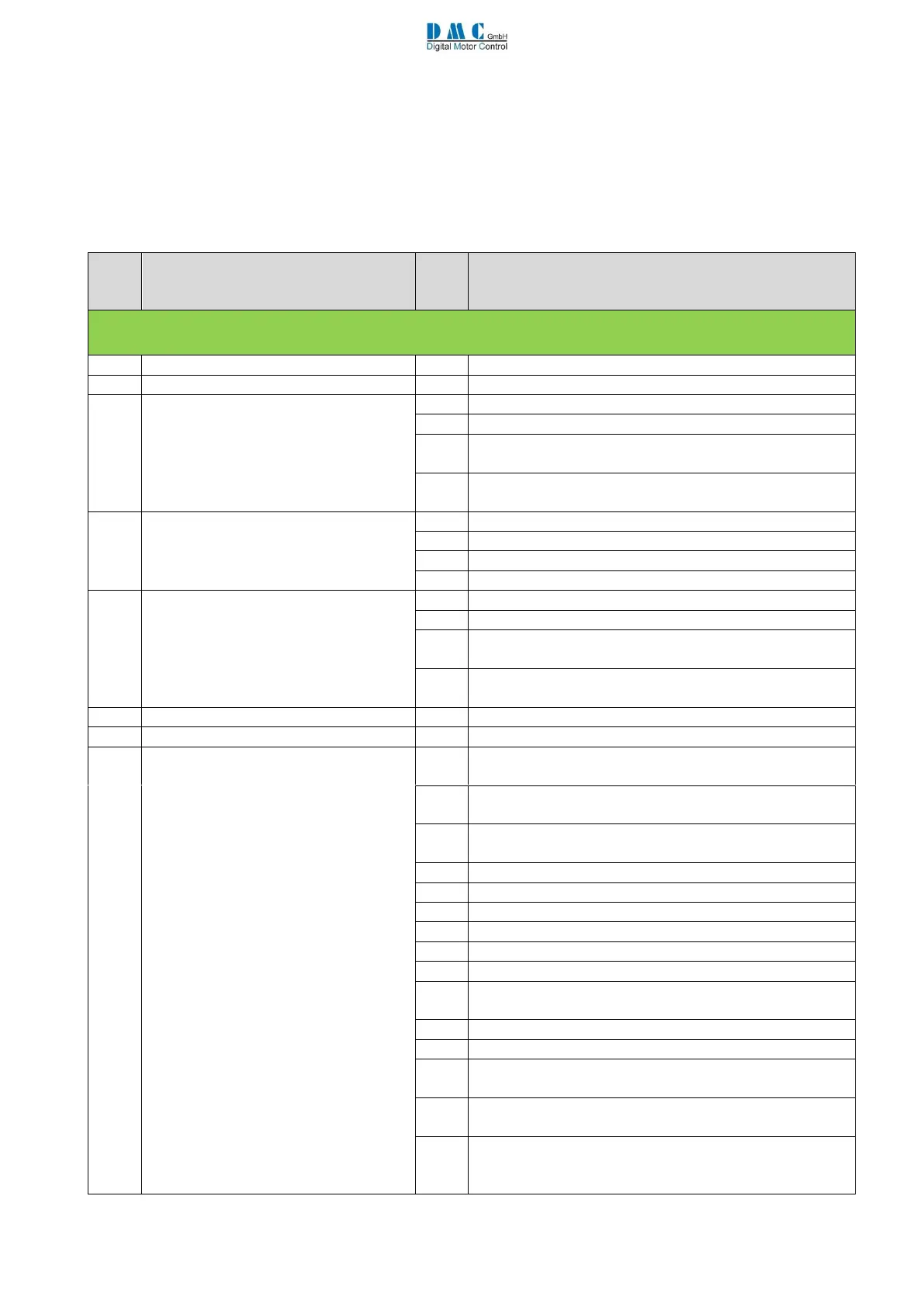

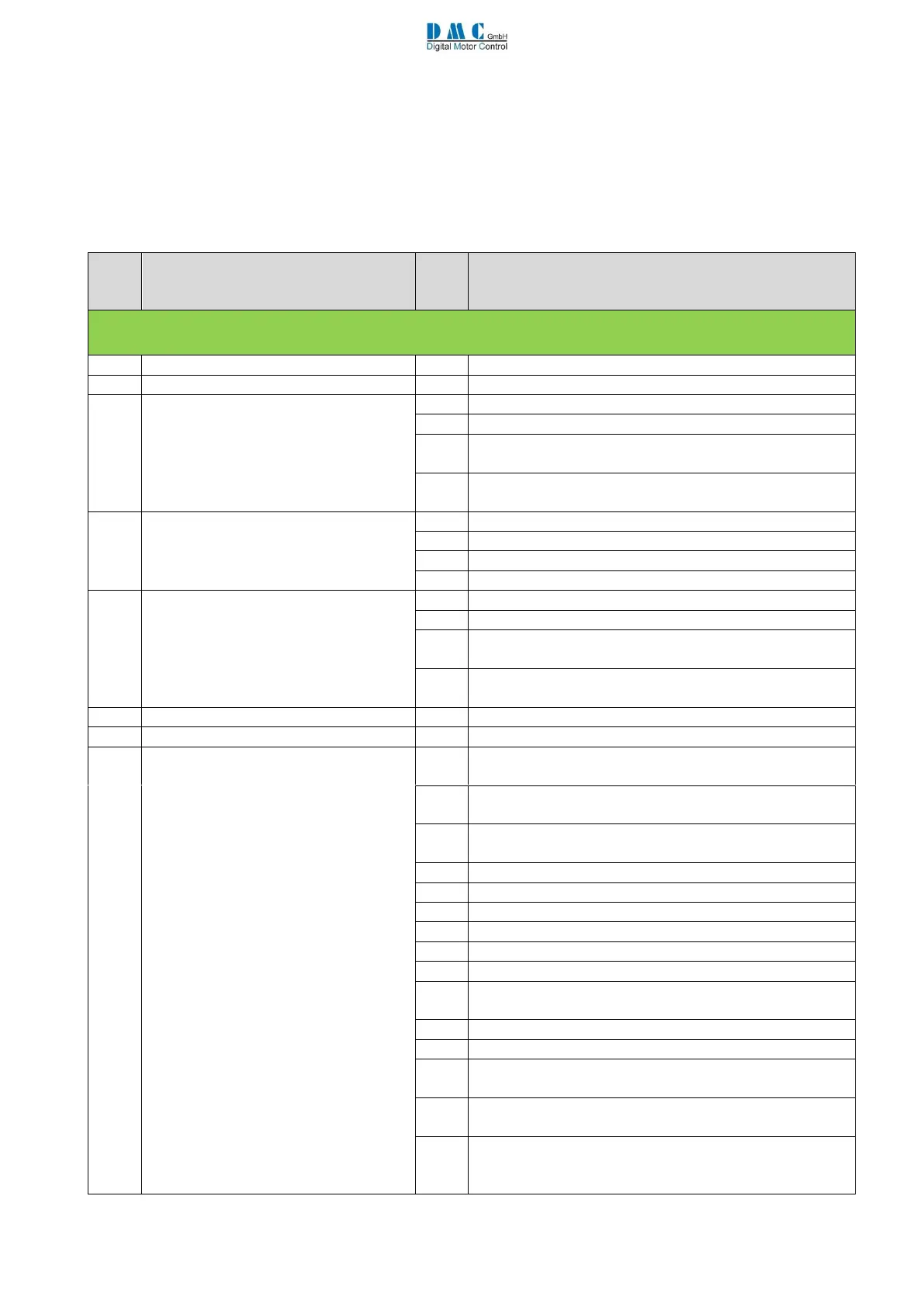

10 DIAGNOSTICS

10.1 Error Codes

The following tables describe all the error codes that the controller will display. The presence of an error can be

detected by means of a red led flashing on controller (number of flashes correspond to base error code) and

investigated in 9.4 Menu 2 “Status”.

The error codes are divided in four different categories, based upon the severity of the faults.

Controller warning faults - Reduces only performance - Fault will reset itself (if possible)

Battery voltage below absolute minimum

Capacitor voltage below absolute minimum

Battery voltage below LV cut back adjustment (drive cut

back active)

Capacitor voltage below LV cut off adjustment (drive cut

back active)

Inhibit drive/ BDI Cut / BLC via can

BDI Cut out (Battery below BDI cut Level)

Pump inhibit input active (Only Pump Software)

BCL via CAN message time out

BCL via CAN message toggle security bit fail

Battery voltage above absolute minimum

Capacitor voltage above absolute minimum

Battery voltage above High Voltage cut back adjustment

(brake cut back active)

Capacitor voltage above High Voltage cut back adjustment

(brake cut back active)

Controller temperature high

Master does not share the line contactor but any one of

the slave does

Master shares the line contactor but one of the requested

slave doesn’t

A slave node number larger than last sharing node also

share the line contactor

WigWag is enabled but walkie is not

inching and walkie are both enabled

dual motor with speed control mode

shared LC and Control Via CAN HMI both active

Inching and Control Via CAN HMI both active

Walkie and Control Via CAN HMI both active

Control Via CAN HMI enabled and CAN node number set

as master

Hill hold Enabled and Torque control enabled

CAN control type options are active but Control Via CAN

HMI is not enabled.

Can Node ID via digital input enabled but control but

Control Via CAN HMI is not enabled.

means Shared Line Contactor HMI option is activated

(“ShareLC”>=2) on but not control via CAN HMI active

(CANMsgs>=4). Solution set CANMsgs < 4.

Errors continue at next page…

Loading...

Loading...