1 DC1 device series

1.9 Maintenance and inspection

26 DC1 frequency inverter 10/12 MN04020003Z-EN www.eaton.com

1.9 Maintenance and inspection

DC1 series frequency inverters will be maintenance-free as long as the gen-

eral rated operational data ( Section 1.4.3, „General rated operational

data“, page16) is adhered to and the specific technical data (see appendix)

for the corresponding ratings is taken into account. Please note, however,

that external influences may affect the operation and lifespan of a DC1 fre-

quency inverter.

We therefore recommend that the devices are checked regularly and the

following maintenance measures are carried out at the specified intervals.

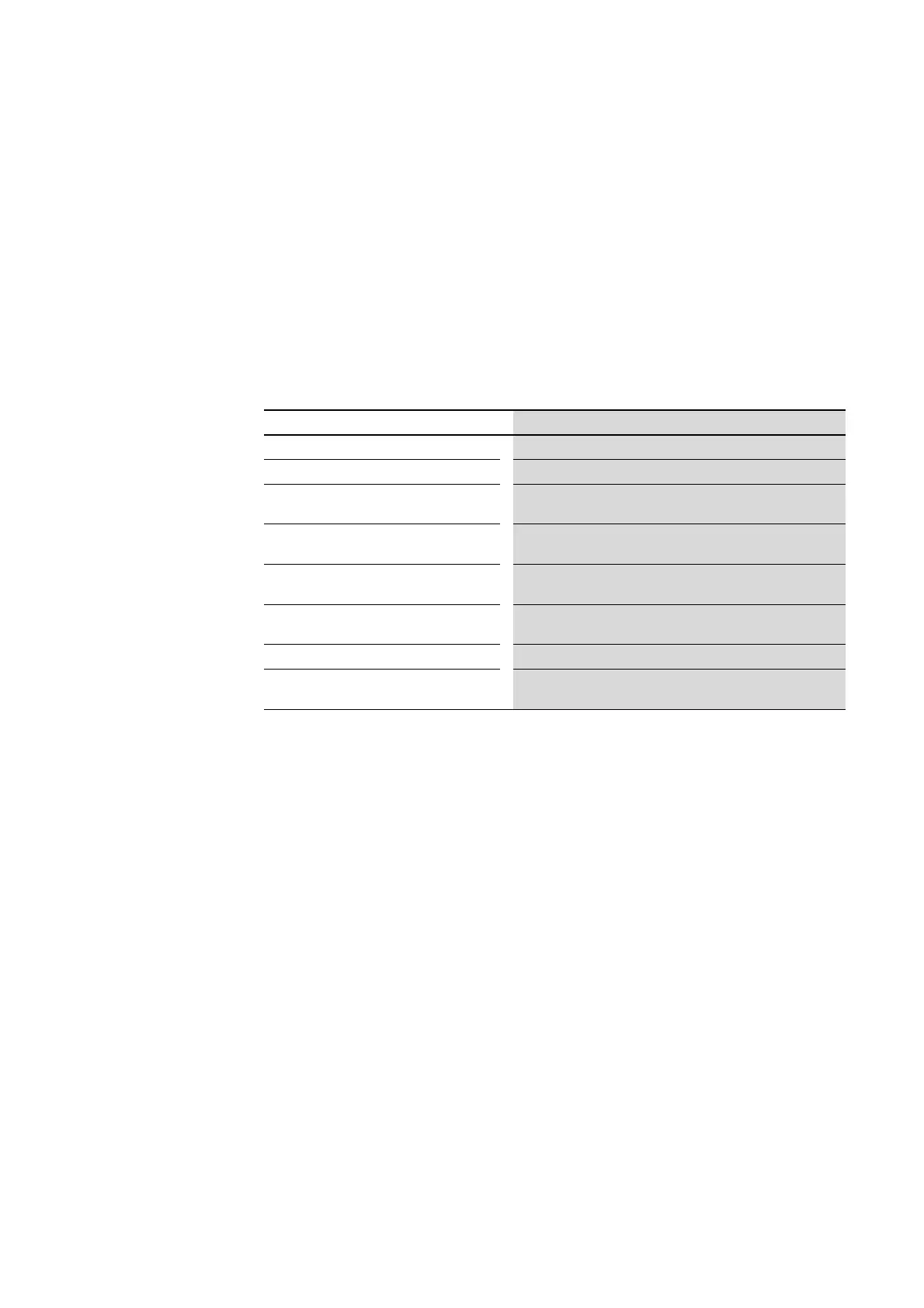

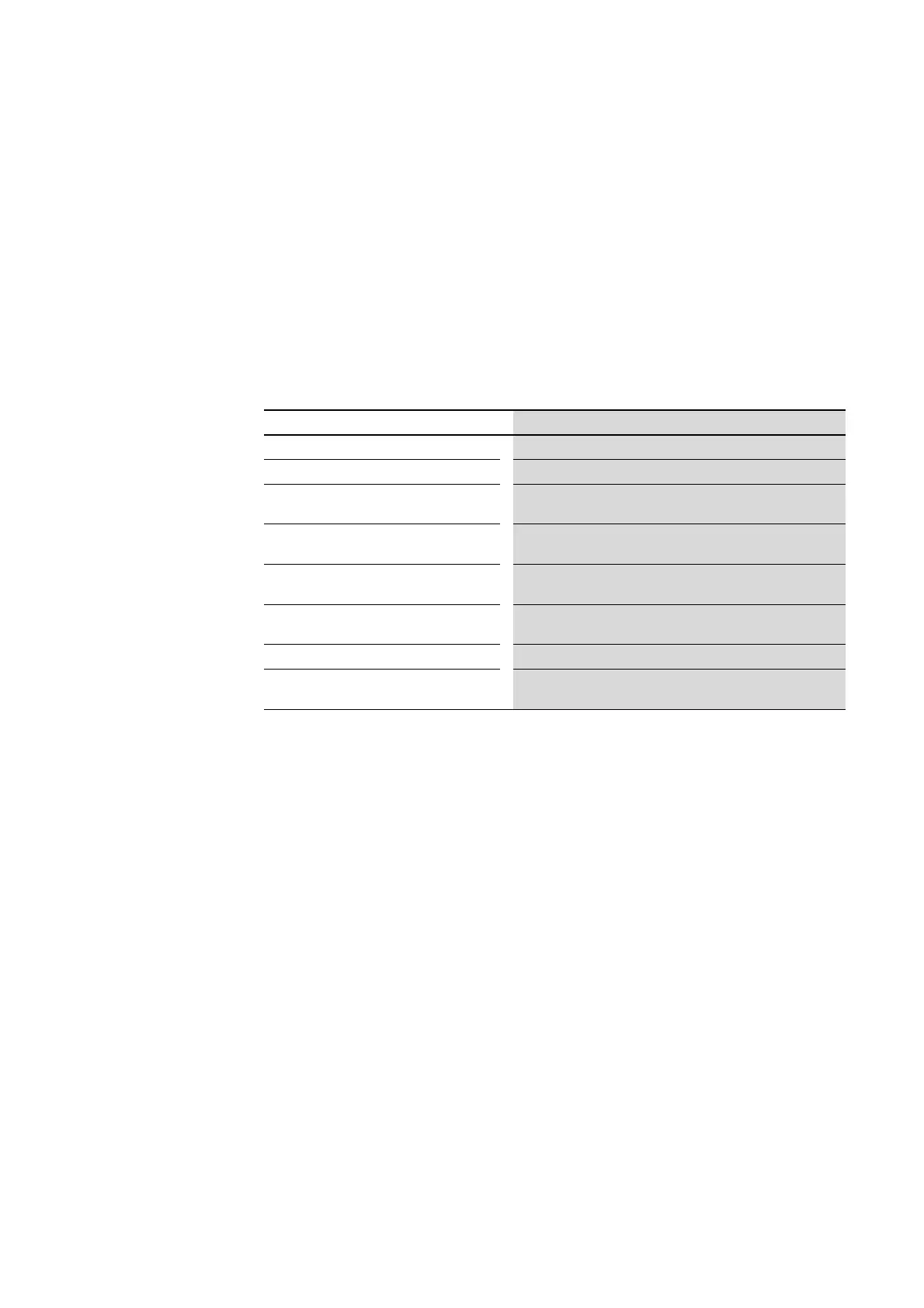

Table 2: Recommended maintenance for DC1 frequency inverters

There are no plans for replacing or repairing individual components of DC1

frequency inverters.

If the DC1 frequency inverter is damaged by external influences, repair is not

possible.

Dispose of the device according to the applicable environmental laws and

provisions for the disposal of electrical or electronic devices.

1.10 Storage

If the DC1 frequency inverter is stored before use, suitable ambient condi-

tions must be ensured at the site of storage:

• Storage temperature: -40 - +70 °C,

• Relative average air humidity: < 95 %, non condensing (EN 50178),

• To prevent damage to the RASP DC link capacitors, storage times longer

than 12 months are not recommended

( Section 1.11, „Charging the internal DC link capacitors“).

Maintenance measures Maintenance interval

Clean cooling vents (cooling slits) Please enquire

Check the fan function 6 - 24 months (depending on the environment)

Check the filter in the control panel doors

(see the manufacturer's specifications)

6 - 24 months (depending on the environment)

Check all earth connections to make sure they

are intact

On a regular basis, at periodic intervals

Check the tightening torques of the terminals

(control signal terminals, power terminals)

On a regular basis, at periodic intervals

Check connection terminals and all metallic

surfaces for corrosion

6 - 24 months; when stored, no more than 12 months later

(depending on the environment)

Motor cables and shield connection (EMC)

According to manufacturer specifications, no later than 5 years

Charge capacitors

12 months

(→ Section 1.11, „Charging the internal DC link capacitors“)

Loading...

Loading...