6 Parameters

DC1 Frequency Inverter 10/12 MN04020003Z-EN www.eaton.com 93

6 Parameters

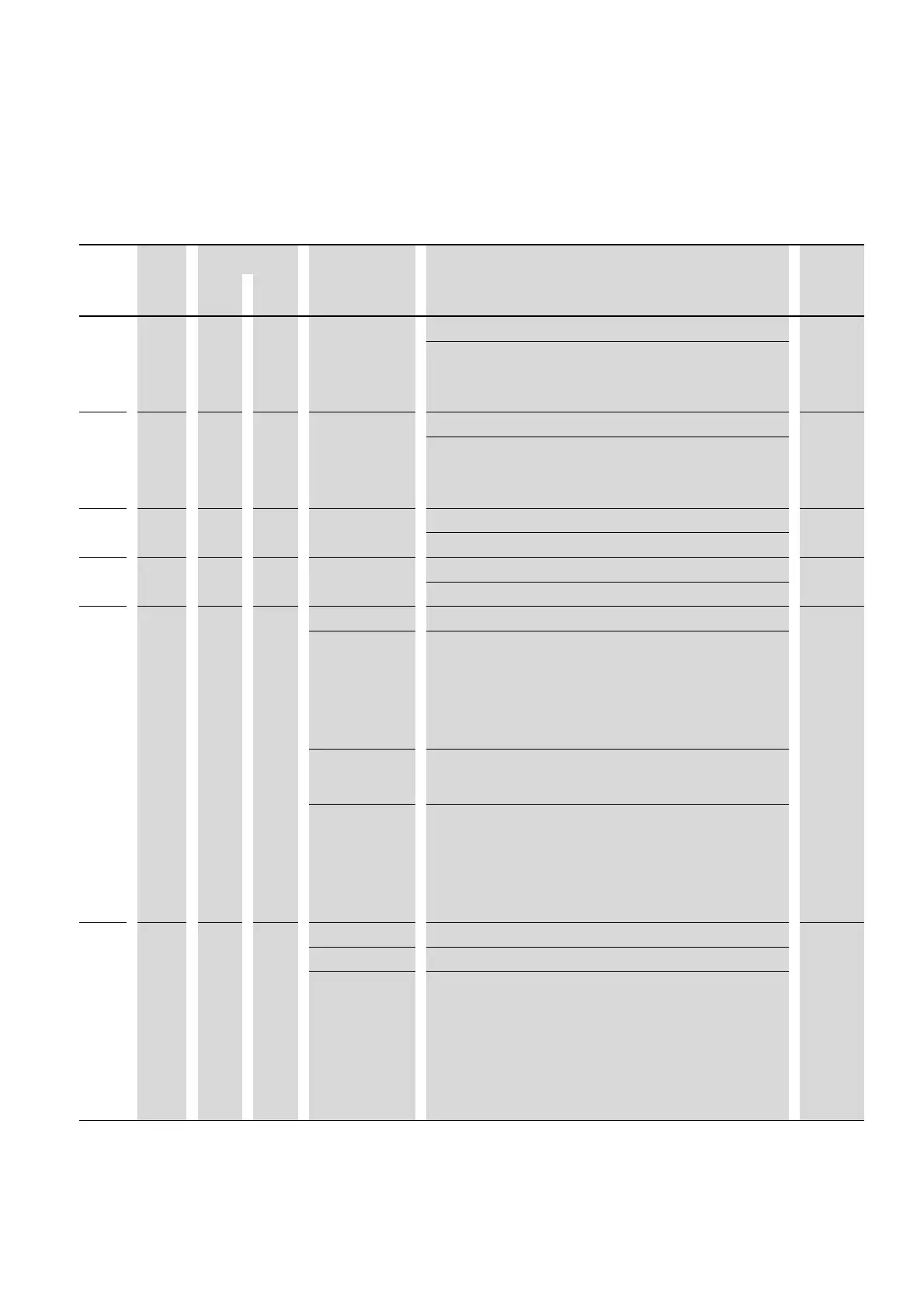

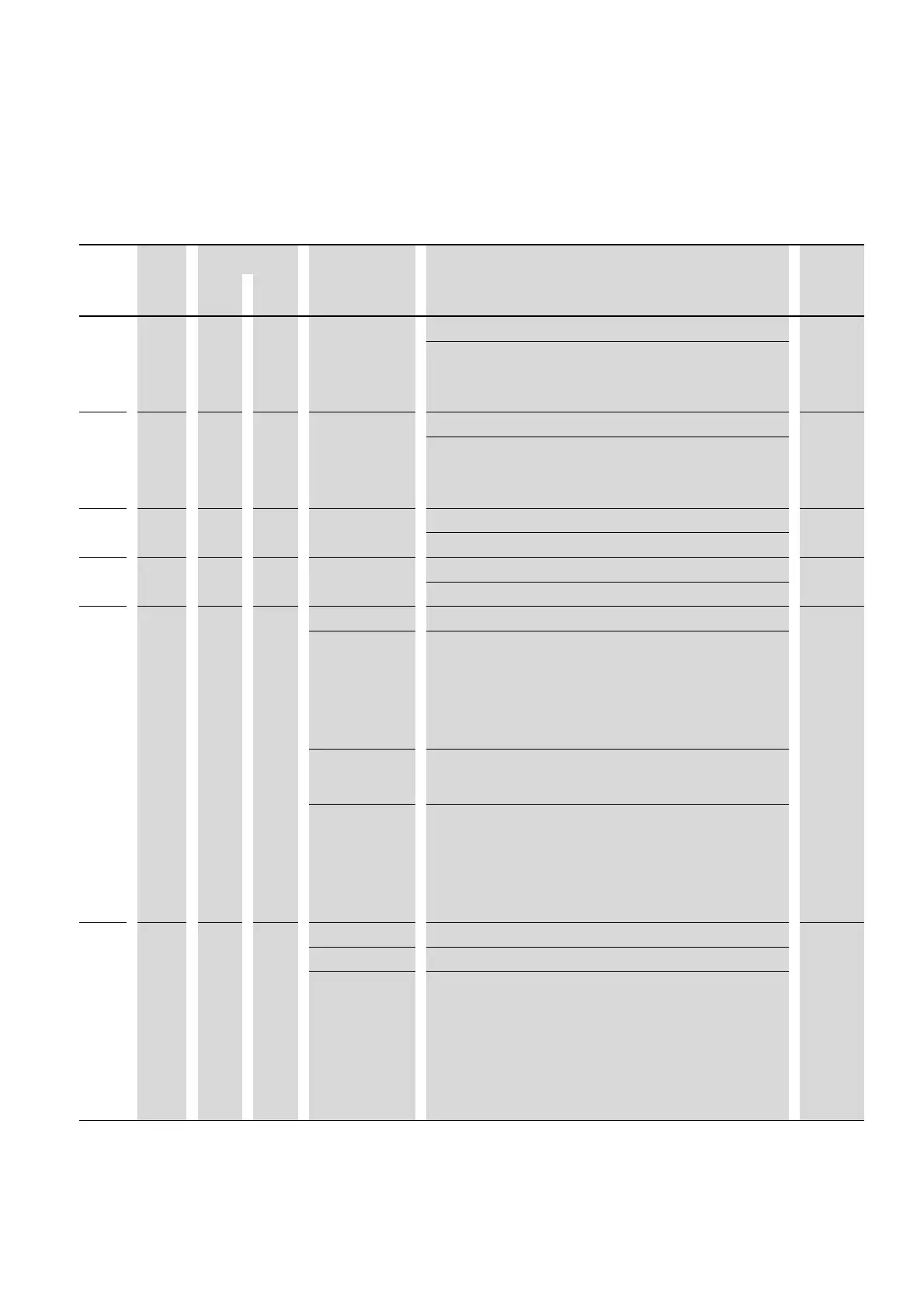

Table 12: Description list for DC1 parameters

PNU

ID Access rights Value Description DS

RUN ro/rw

P-01 129 ✓ rw Maximum frequency / maximum speed 50.0

P-10 = 0 → P-02 - 5 x P-09 → Hz

P-10 > 0 → P02 - 5 x P-09 x 60 s → min-1

The maximum output frequency / motor speed limit – shown in Hz or

rpm (if P-10 > 0).

P-02

130 ✓ rw Minimum frequency / minimum speed 0

P-10 = 0 → 0 - P-01 → Hz

P-10 > 0 → 0 - P01 → min-1

The minimum output frequency / minimum speed – shown in Hz or rpm

(if P-10 > 0).

P-03

131 ✓ rw Acceleration time (acc1) 5

0.1-600s (→ Figure 68, page 119)

P-04 132 ✓ rw Deceleration time (dec1) 5

0.1-600s (→ Figure 68, page 119)

P-05 133 ✓ rw Stop Function 1

0 Ramp, deceleration = dynamic braking

Deceleration time with the value set under P-04 (dec1).

If the energy that is fed back by the motor during dynamic braking is too

high, the deceleration time must be increased.

In devices with an internal braking transistor, the excess energy can be

dissipated with an external braking resistor (optional)

(→ Section 6.2.11.2, „Regenerative braking“, page132)

1 Free coasting

After the start enable (FWD/REV) is switched off or the STOP push-

button is pressed (P-12 and P-15), the motor will coast uncontrolled.

2 Ramp, quick stop = dynamic braking

Deceleration time 2 with the value set under P-24 (dec2)

If the energy that is fed back by the motor during dynamic braking is too

high, the deceleration time must be increased.

In devices with an internal braking transistor, the excess energy can be

dissipated with an external braking resistor (optional)

(→ Section 6.2.11.2, „Regenerative braking“, page132)

P-06

134 ✓ rw Energy optimization 0

0 Deactivated

1 activated

If this option is selected, the energy optimization function will attempt

to reduce the total energy consumed by the frequency inverter and the

motor during operation at constant speeds and with light loads. The

output voltage applied at the motor will be reduced.

The energy optimization function is intended for applications in which

the frequency inverter is run for specific periods at a constant speed

and with a light load, independently of whether the torque is constant

or varies.

Loading...

Loading...