Installation Proline Prosonic Flow 93T Portable

12 Endress+Hauser

3.2.5 Sensor selection and arrangement

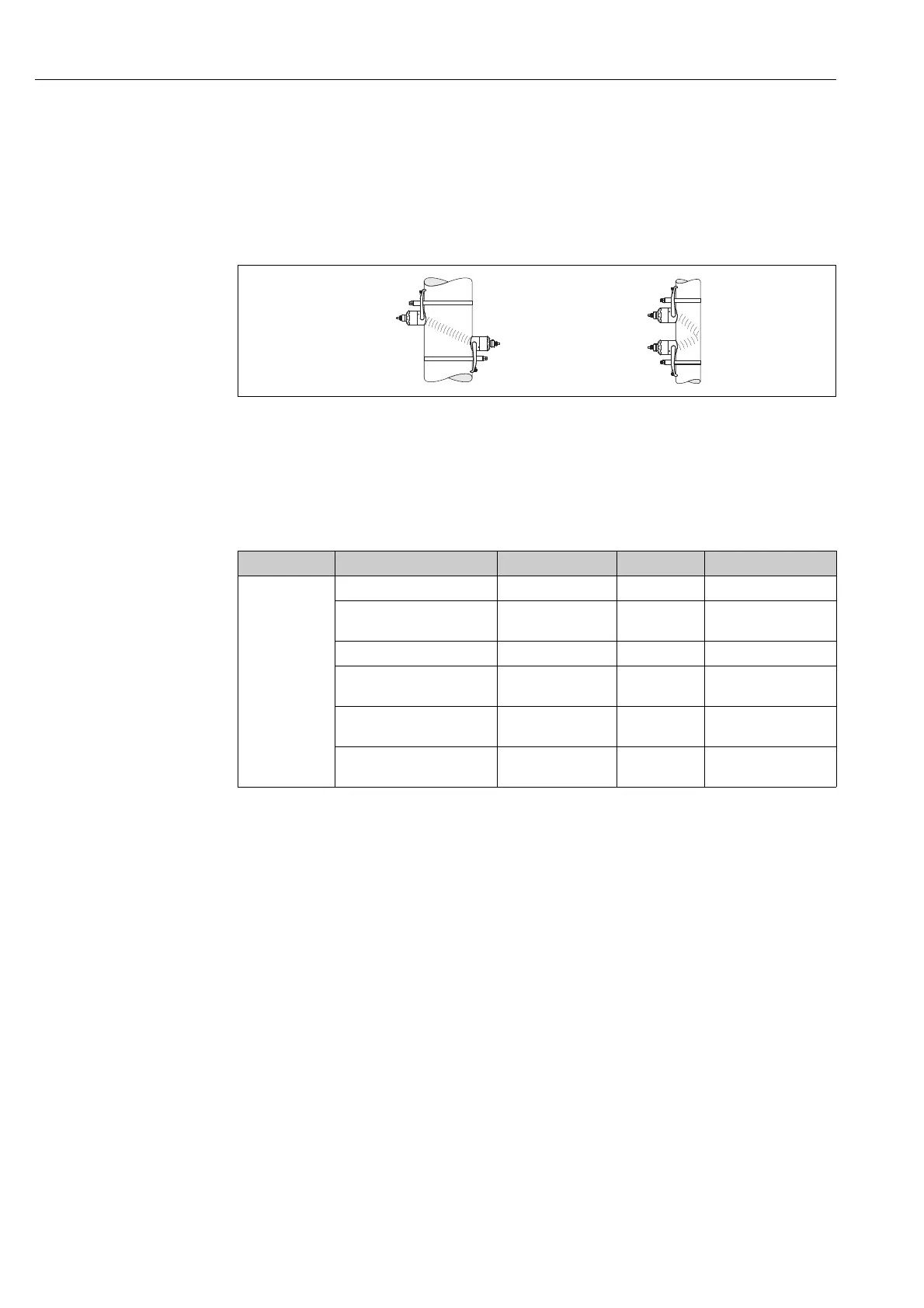

The sensors can be arranged differently:

• Mounting arrangement for measurement via one traverse: the sensors are located on opposite

sides of the pipe.

• Mounting arrangement for measurement via two traverses: the sensors are located on the same

side of the pipe.

A0001108

Fig. 6: Sensor mounting arrangement

A Mounting arrangement for measurement via one traverse

B Mounting arrangement for measurement via two traverses

The number of traverses required depends on the sensor type, the nominal diameter and the

thickness of the pipe wall. We recommend the following types of mounting:

Sensor Type Nominal Diameter Sensor Frequency Sensor ID Type of Mounting

1)

Prosonic Flow P

DN 15 to 65 (½ to 2½") 6 MHz P-CL-6F* 2 (or 1) traverses

4)

DN 50 to 65 (2 to 2½") 6 MHz (or 2 MHz)

P-CL-6F*

P-CL-2F*

2 (or 1) traverses

2)

DN 80 (3") 2 MHz P-CL-2F* 2 traverses

DN 100 to 300 (4 to 12") 2 MHz (or 1 MHz)

P-CL-2F*

P-CL-1F*

2 traverses

3)

DN 300 to 600 (12 to 24") 1 MHz (or 2 MHz)

P-CL-1F*

P-CL-2F*

2 traverses

3)

DN 650 to 4000 (26 to 160") 1 MHz (or 0.5 MHz)

P-CL-1F*

W-CL-05F*

1 traverse

3)

1)

The installation of clamp-on sensors is principally recommended in the 2 traverse type installation. This type of

installation allows the easiest and most comfortable type of mounting and means that a system can also be mounted

even if the pipe can only be accessed from one side. However, in certain applications a 1 traverse installation may be

preferred. These include:

• Certain plastic pipes with wall thickness > 4 mm (0.16")

• Pipes made of composite materials such as GRP

• Lined pipes

• Applications with fluids with high acoustic damping

2)

If the pipe nominal diameter is small (DN 65 / 2½" and smaller), the sensor spacing with Prosonic Flow P can be too

small for two traverse installation using sensor P-CL-2F*. In this case, the 1 traverse type of installation must be used.

3)

0.5 MHz sensors (Prosonic Flow W) are also recommended for applications with composite material pipes such as

GRP and may be recommended for certain lined pipes, pipes with wall thickness > 10 mm (0.4"), or applications with

media with high acoustic damping. In addition, for these applications we principally recommend mounting the

W sensors in a 1 traverse configuration.

4)

6 MHz sensors for applications with flow velocity < 10 m/s.

Loading...

Loading...