Maintenance 6. Joint #3 (Replacing the Reduction Gear Unit)

138 S5 Rev.5

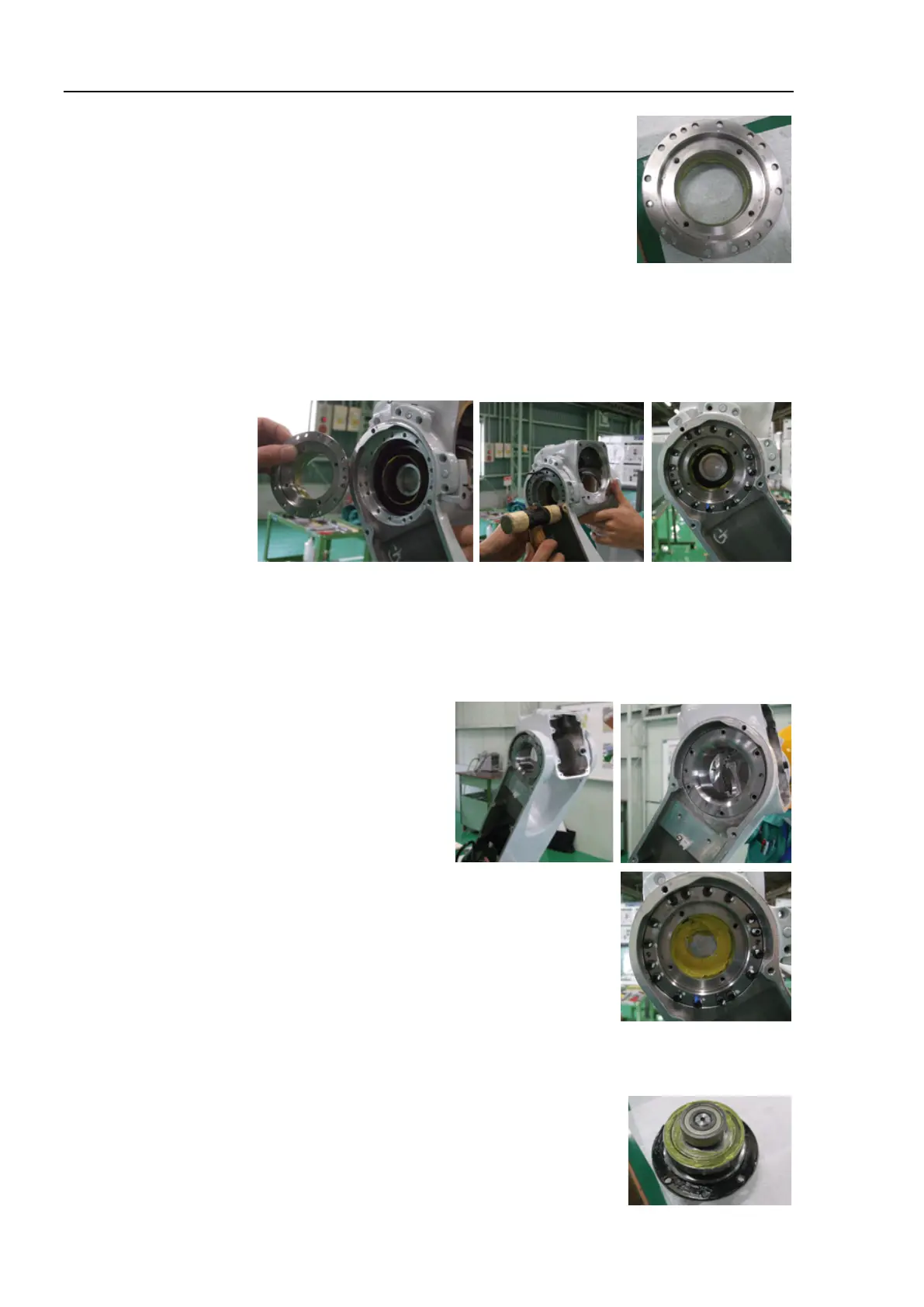

Apply grease on teeth of the circular spline.

Grease for reduction gear unit: SK-1A

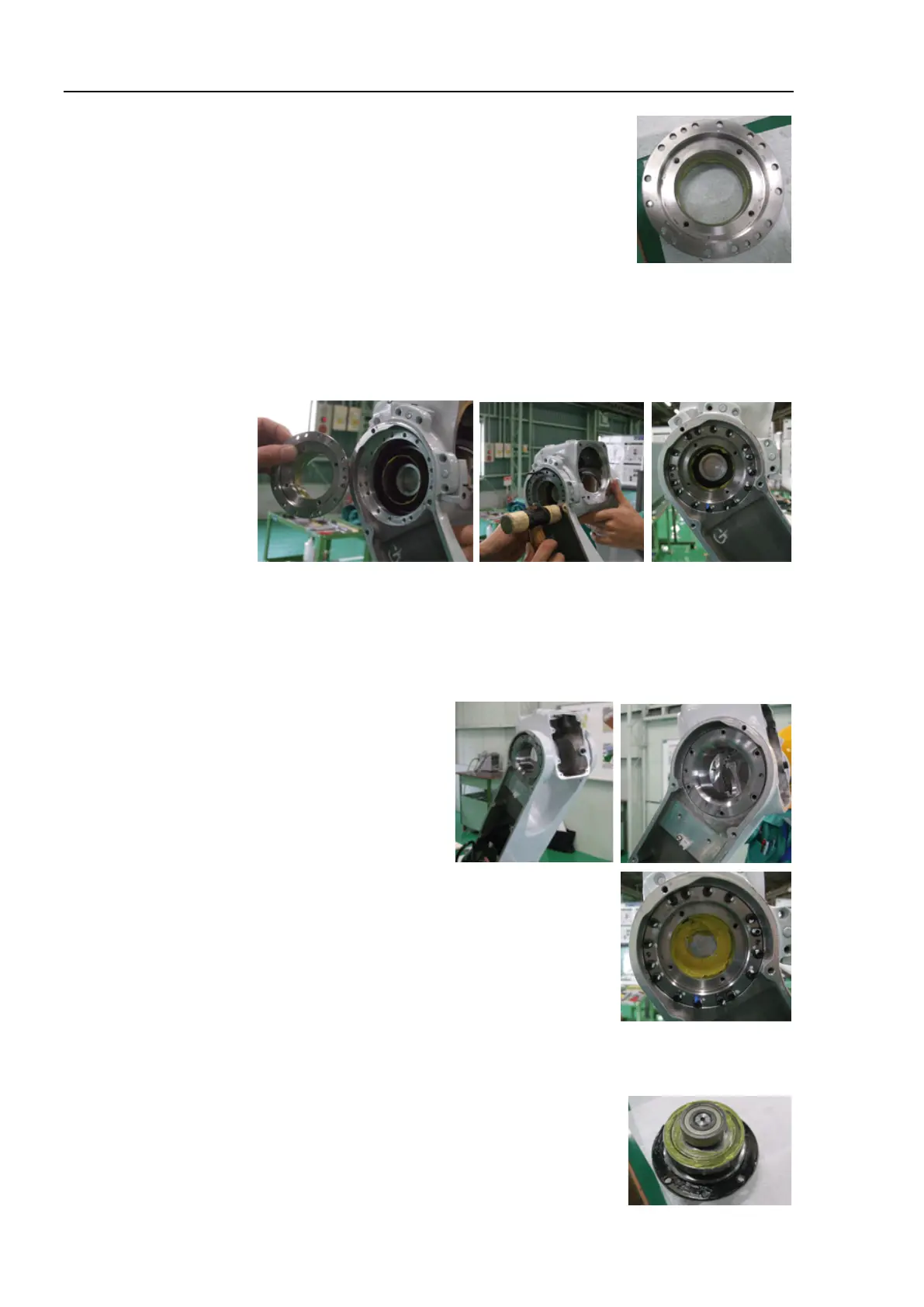

Insert the bearing into the opposite side of the Arm #3

’

s reduction gear unit mounting

surface.

Pass the circular spline through

the Arm #2 and Arm #3 and joint the arms.

Hexagon socket head cap bolt: 16-M4×12

Tightening torque : 2.8 N·m (0.29 kgf·m)

Insert the housing into the Arm #2 and bearing.

GT-SA bolt : 6-M4×10

Tightening torque : 2.8 N·m (0.29 kgf·m)

housing is not easily inserted, tap the housing

using a plastic hammer or similar

tool.

-

thick grease for the reduction gear unit to

the inner periphery of the flexspline.

Grease for reduction gear unit: SK-1A

grease to the bearing of waveform generator.

Grease for reduction gear unit: SK-1A

liquid gasket to the surfaces of the housing (with

the waveform generator mounted)

and circular spline.

Loading...

Loading...