ESAB CUTMASTER 80

INTRODUCTION Manual0-5396

2T-2

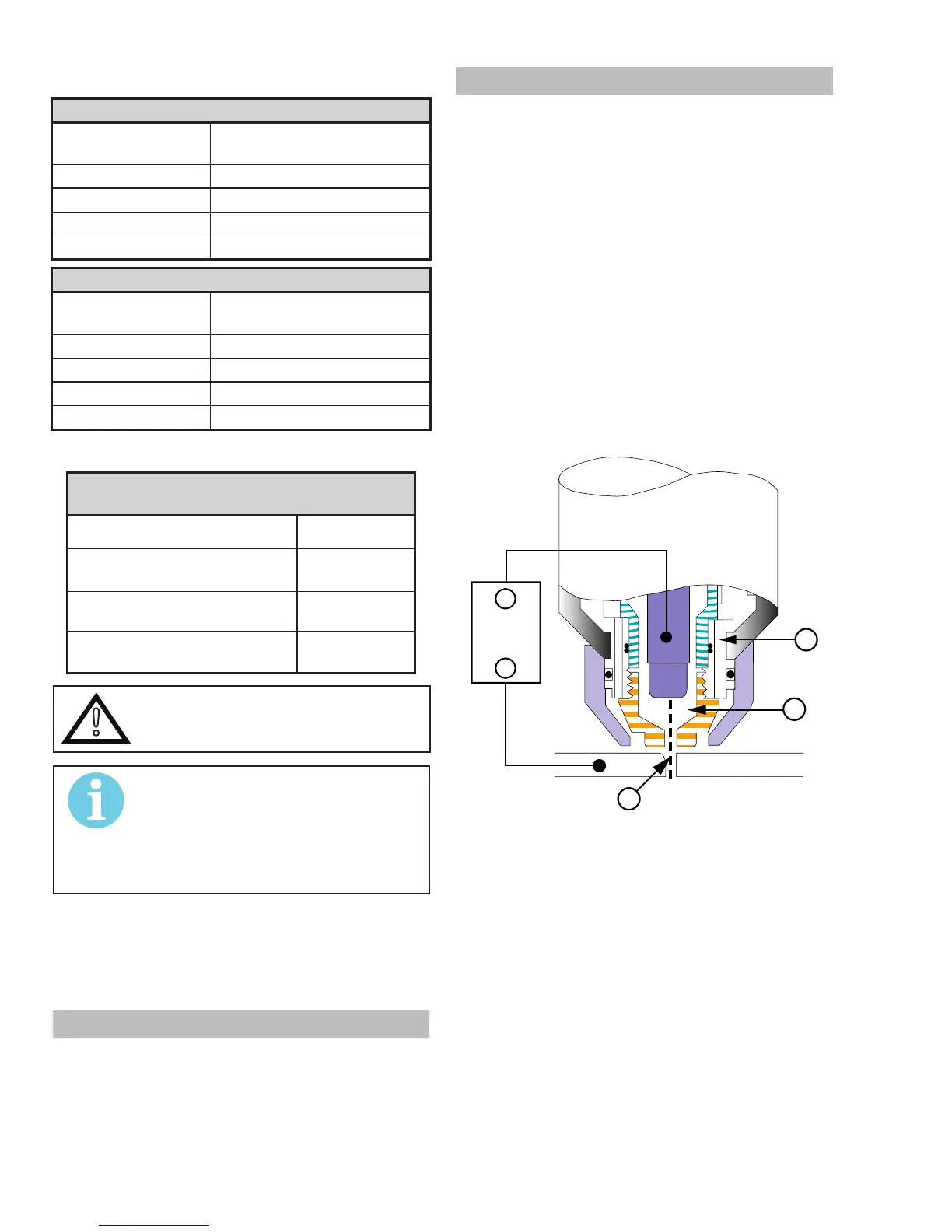

F. Torch Ratings

Manual Torch Ratings

Ambient

Temperature

104° F

40° C

Duty Cycle 100% @ 60 Amps @ 400 scfh

MaximumCurrent 80 Amps

Voltage (V

peak

) 500V

Arc Striking Voltage 7kV

MechanizedTorchRatings

Ambient

Temperature

104° F

40° C

Duty Cycle 100% @ 100 Amps @ 400 scfh

MaximumCurrent 120 Amps

Voltage (V

peak

) 500V

Arc Striking Voltage 7kV

G. Gas Requirements

ManualandMechanizedTorchGas

Specications

Gas (Plasma and Secondary) Compressed Air

Operating Pressure

Refer to NOTE

60 - 95 psi

4.1 - 6.5 bar

MaximumInputPressure 125 psi / 8.6 bar

Gas Flow (Cutting and

Gouging)

300 - 500 scfh

142 - 235 lpm

!

WARNING

This torch is not to be used with

oxygen (O

2

)

NOTE!

Operatingpressurevarieswithtorch

model,operatingamperage,and

torch leads length. Refer to gas

pressure settings charts for each

model.

H. DirectContactHazard

For standoff tip the recommended standoff is 3/16

inches / 4.7 mm.

2T.04 Options And Accessories

Foroptionsandaccessories,seesection6.

2T.05 Introduction to Plasma

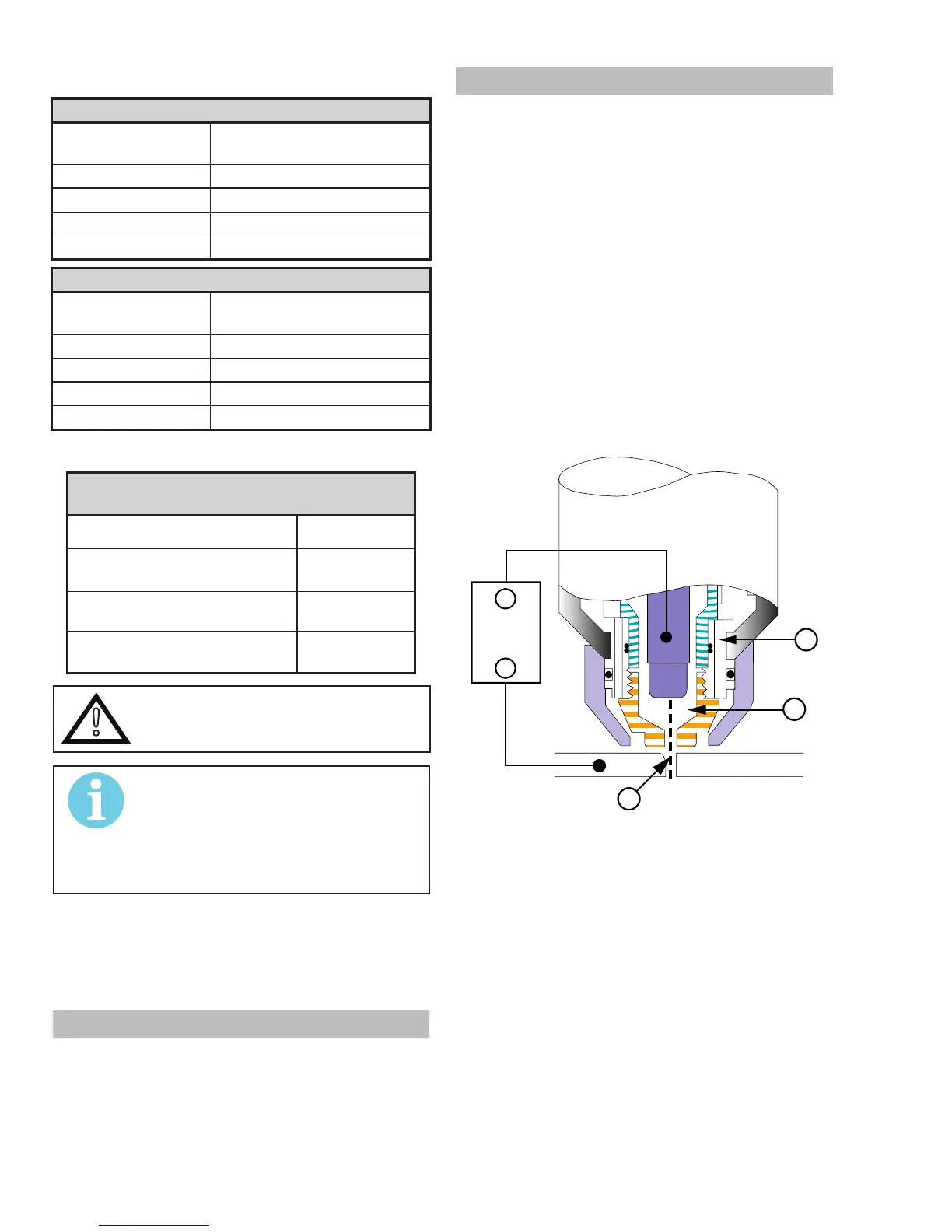

A. Plasma Gas Flow

Plasma is a gas which has been heated to an

extremely high temperature and ionized so that it

becomeselectricallyconductive.Theplasmaarc

cutting and gouging processes use this plasma to

transfer an electrical arc to the workpiece. The metal

tobecutorremovedismeltedbytheheatofthearc

and then blown away.

While the goal of plasma arc cutting is separation of

thematerial,plasmaarcgougingisusedtoremove

metals to a controlled depth and width.

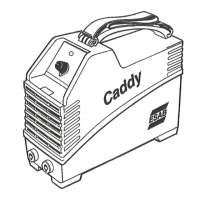

InaPlasmaCuttingTorchacoolgasentersZoneB,

where a pilot arc between the electrode and the torch

tip heats and ionizes the gas. The main cutting arc

then transfers to the workpiece through the column

ofplasmagasinZoneC.

A-00002

Workpiece

Power

Supply

+

_

C

B

A

Typical Torch Head Detail

By forcing the plasma gas and electric arc through a

smallorice,thetorchdeliversahighconcentration

ofheattoasmallarea.Thestiff,constrictedplasma

arcisshowninZoneC.Directcurrent(DC)straight

polarityisusedforplasmacutting,asshowninthe

illustration.

ZoneA channels a secondary gas that cools the

torch.Thisgasalsoassiststhehighvelocityplasma

gas in blowing the molten metal out of the cut allow-

ingforafast,slag-freecut.

Loading...

Loading...