ESAB CUTMASTER 80

Manual0-5396 OPERATION

4T-7

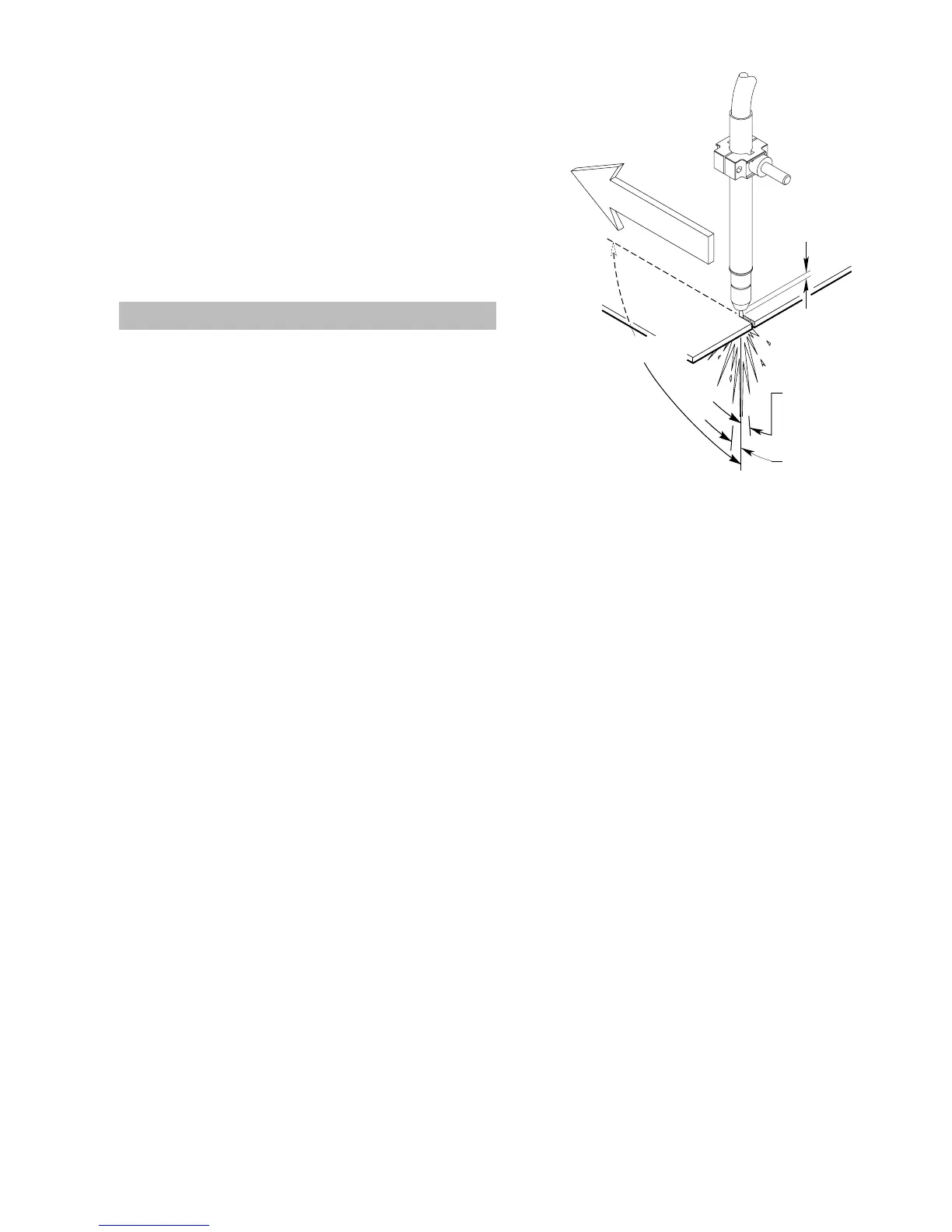

Slag Buildup

Slag generated by gouging on materials such as car-

bonandstainlesssteels,nickels,andalloyedsteels,

canberemovedeasilyinmostcases.Slagdoesnot

obstruct the gouging process if it accumulates to the

sideofthegougepath.However,slagbuild-upcan

causeinconsistenciesandirregularmetalremoval

if large amounts of material build up in front of the

arc. The build - up is most often a result of improper

travelspeed,leadangle,orstandoffheight.

4T.06MechanizedTorchOperation

CuttingWithMechanizedTorch

Themechanizedtorchcanbeactivatedbyremote

control pendant or by a remote interface device

suchasCNC.

1. Tostartacutattheplateedge,positionthecenter

of the torch along the edge of the plate.

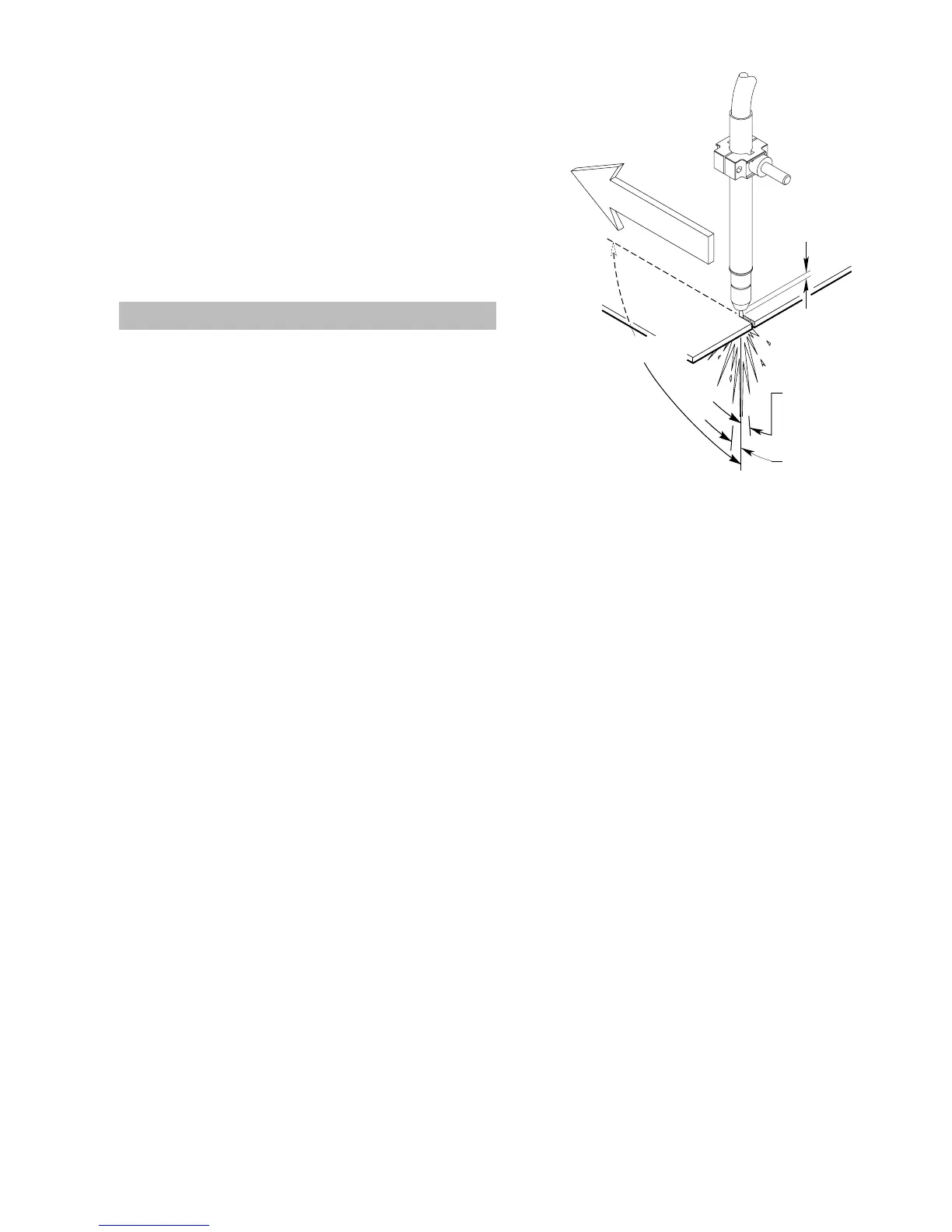

Travel Speed

Propertravelspeedisindicatedbythetrailofthe

arc which is seen below the plate. The arc can be

oneofthefollowing:

1. Straight Arc

A straight arc is perpendicular to the workpiece

surface. This arc is generally recommended

for the best cut using air plasma on stainless or

aluminum.

2. Leading Arc

The leading arc is directed in the same direction

astorchtravel.Avedegreeleadingarcisgen-

erally recommended for air plasma on mild steel.

3. Trailing Arc

The trailing arc is directed in the opposite direc-

tionastorchtravel.

Standoff Distance

Straight Arc

Trailing Arc

Leading Arc

Direction of Torch Travel

A-02586

Mechanized Torch Operation

Foroptimumsmoothsurfacequality,thetravelspeed

shouldbe adjustedsothatonlytheleadingedge

ofthearc column producesthecut. If thetravel

speedistooslow,aroughcutwillbeproducedas

thearcmovesfromsidetosideinsearchofmetal

for transfer.

Travelspeedalsoaffectsthebevelangleofacut.

Whencuttinginacircleoraroundacorner,slowing

downthetravelspeedwillresultinasquarercut.

The power source output should be reduced also.

Refer to the appropriate Control Module Operating

ManualforanyCornerSlowdownadjustmentsthat

may be required.

Piercing With Machine Torch

Topiercewithamachinetorch,thearcshouldbe

started with the torch positioned as high as possible

abovetheplate whileallowingthearc totransfer

andpierce.Thisstandoffhelpsavoidhavingmolten

metal blow back onto the front end of the torch.

Whenoperatingwithacuttingmachine,apierceor

dwelltimeisrequired.Torchtravelshouldnotbe

enabled until the arc penetrates the bottom of the

plate.Asmotionbegins,torchstandoffshouldbe

reduced to the recommended 1/8 - 1/4 inch (3-6 mm)

distance for optimum speed and cut quality. Clean

spatter and scale from the shield cup and the tip as

soon as possible. Spraying or dipping the shield cup

in anti - spatter compound will minimize the amount

of scale which adheres to it.

Loading...

Loading...