ESAB CUTMASTER 80

OPERATION Manual0-5396

4T-6

7. Clean spatter and scale from the shield cup and

the tip as soon as possible. Spraying the shield

cup in anti - spatter compound will minimize the

amount of scale which adheres to it.

Cuttingspeeddependsonmaterial,thickness,andthe

operator’s ability to accurately follow the desired cut line.

Thefollowingfactorsmayhave animpacton system

performance:

• Torchpartswear

• Airquality

• Linevoltageuctuations

• Torchstandoffheight

• Properworkcableconnection

4T.05 Gouging

!

WARNING

Be sure the operator is equipped

withpropergloves,clothing,eyeand

ear protection and that all safety pre-

cautions at the front of this manual

havebeenfollowed.Makesureno

part of the operator’s body comes in

contact with the workpiece when the

torchisactivated.

Disconnect primary power to the

system before disassembling the

torch,leads,orpowersupply.

!

CAUTION

Sparks from plasma gouging can

causedamagetocoated,paintedor

othersurfacessuchasglass,plas-

tic,andmetal.

Check torch parts. The torch parts

must correspond with the type of

operation.RefertoSection4T.07,

Torch Parts Selection.

Gouging Parameters

Gouging performance depends on parameters such

astorchtravelspeed,currentlevel,leadangle(the

anglebetweenthetorchandworkpiece),andthedis-

tance between the torch tip and workpiece (standoff).

!

CAUTION

Touching the torch tip or shield cup

to the work surface will cause exces-

sivepartswear.

Torch Travel Speed

NOTE!

Refer to Appendix Pages for addi-

tional information as related to the

Power Supply used.

Optimumtorchtravelspeedisdependentoncurrent

setting,leadangle,andmodeofoperation(handor

machine torch).

Current Setting

Currentsettingsdependontorchtravelspeed,

modeofoperation(handormachinetorch),andthe

amountofmaterialtoberemoved.

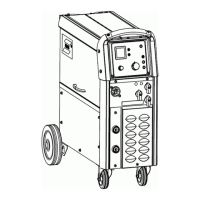

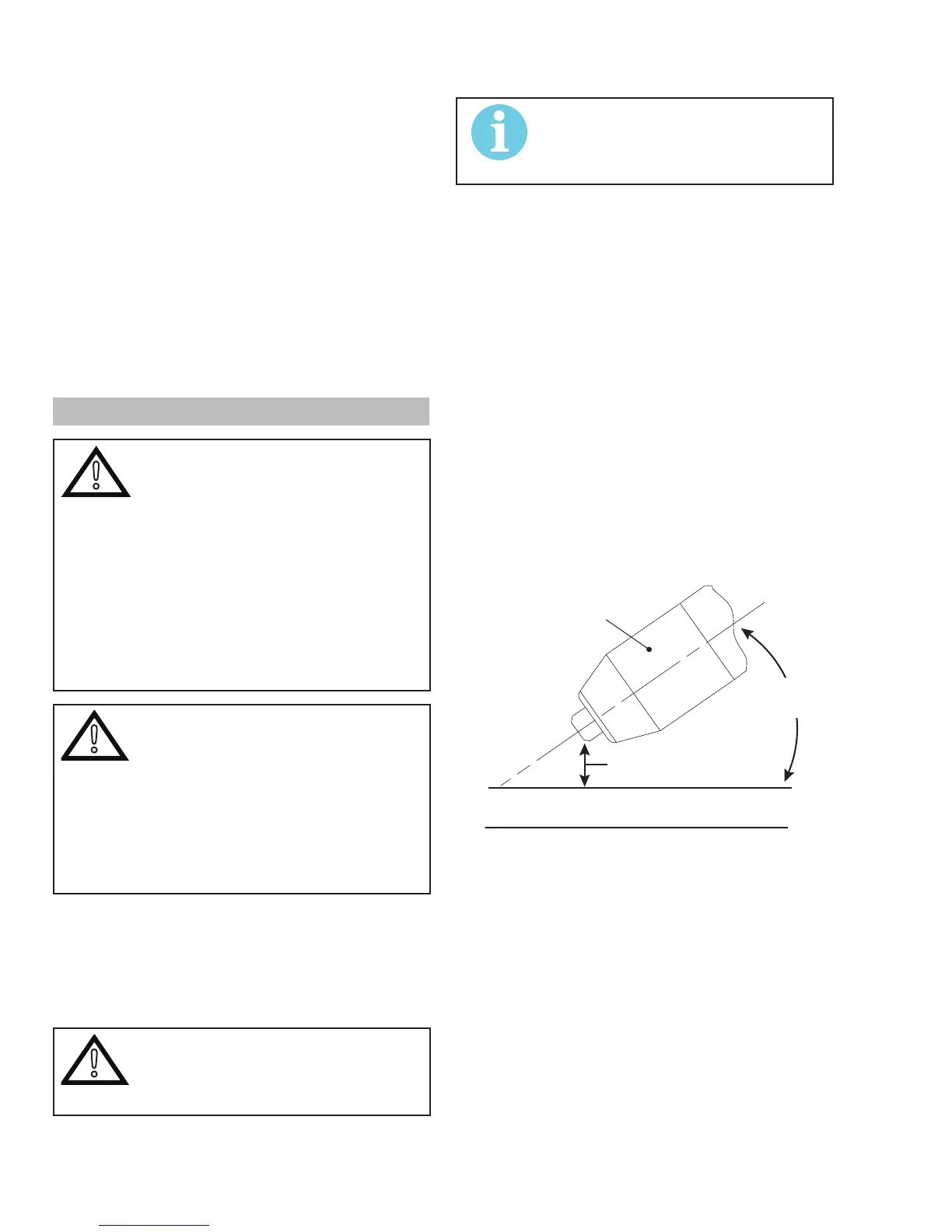

Lead Angle

The angle between the torch and workpiece depends

ontheoutputcurrentsettingandtorchtravelspeed.

The recommended lead angle is 35°. At a lead angle

greater than 45° the molten metal will not be blown

out of the gouge and may be blown back onto the

torch.Iftheleadangleistoosmall(lessthan35°),

lessmaterialmayberemoved,requiringmorepass-

es.Insomeapplications,suchasremovingwelds

orworkingwithlightmetal,thismaybedesirable.

35°

Workpiece

Torch Head

Standoff Height

A-00941_AB

Gouging Angle and Standoff Distance

Standoff Distance

The tip to work distance affects gouge quality and

depth. Standoff distance of 1/8 - 1/4 inch (3 - 6

mm)allowsforsmooth,consistentmetalremoval.

Smallerstandoffdistancesmayresultinaseverance

cut rather than a gouge. Standoff distances greater

than 1/4 inch (6 mm) may result in minimal metal

removalorlossoftransferredmainarc.

Loading...

Loading...