ESAB CUTMASTER 80

Manual0-5396 OPERATION

4-1

SECTION 4 SYSTEM:

OPERATION

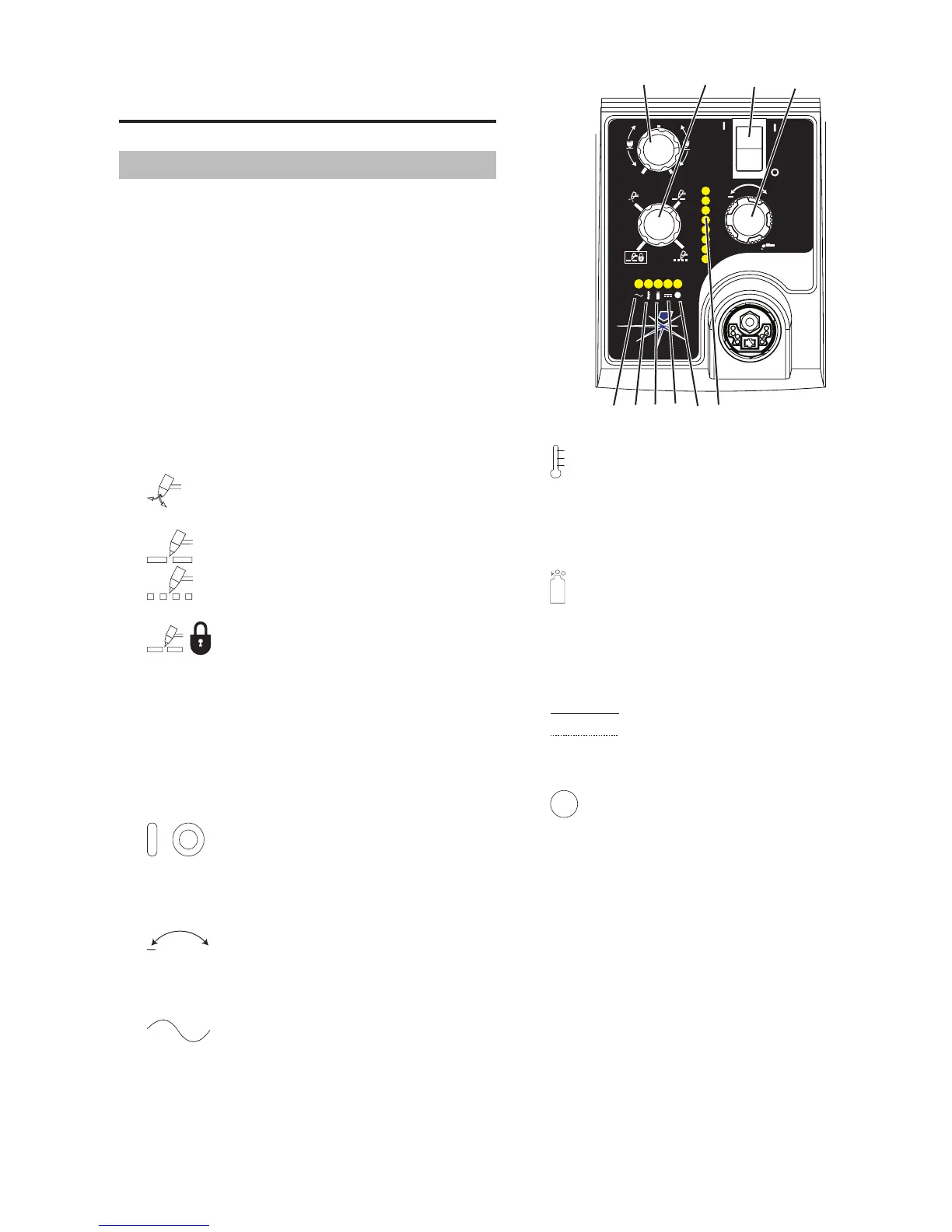

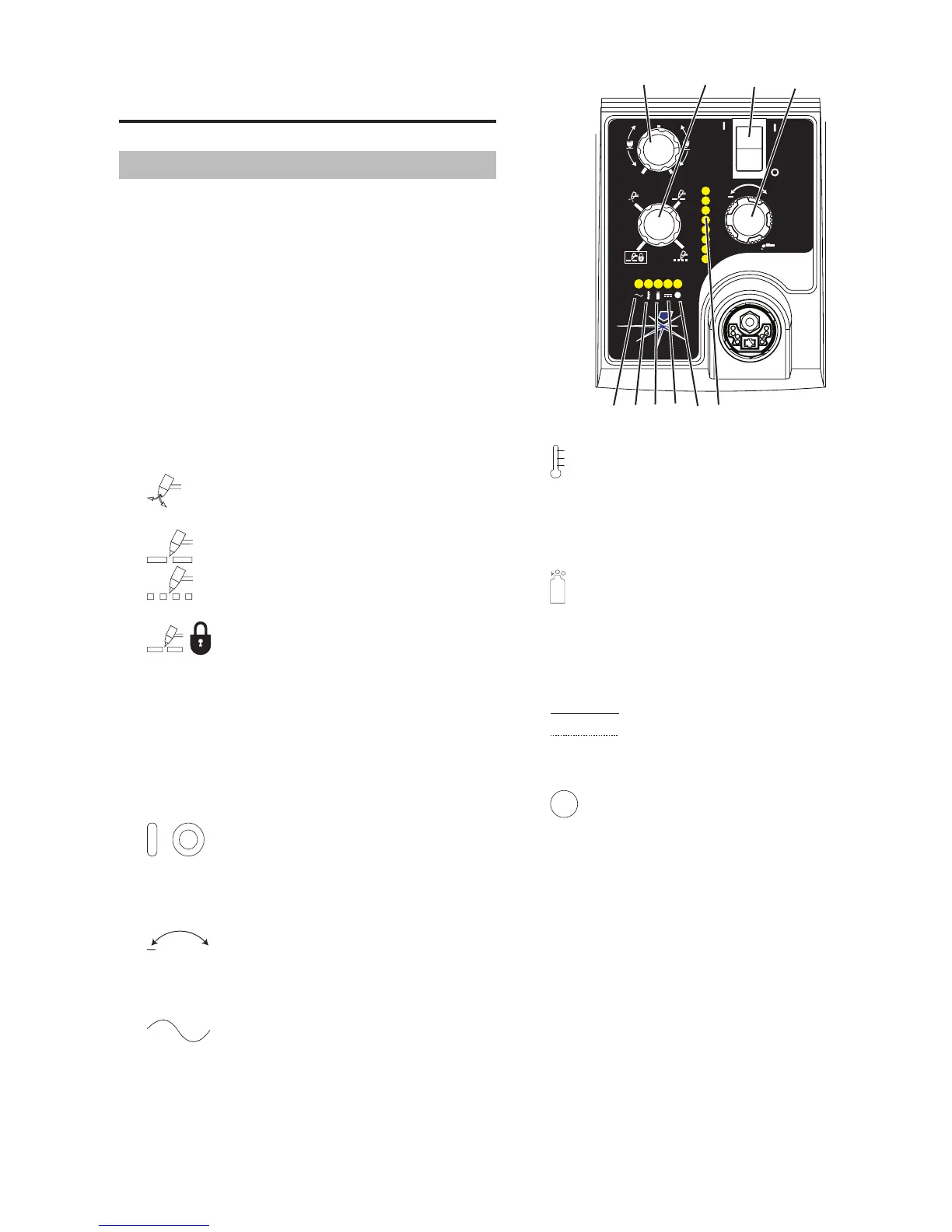

4.01 Front Panel Controls /

Features

SeeIllustrationfornumberingIdentication

1. Output Current Control

Sets the desired output current. Output settings

up to 60 Amps may be used for drag cutting (with

the torch tip contacting the workpiece) or higher for

standoff cutting.

2. Function Control

FunctionControlKnob,Usedtoselectbetweenthe

different operating modes.

SET Used to purge the air through the unit

and torch and leads and to adjust gas pressure.

RUN Used for general cutting operations

RAPID AUTO RESTART Allows for faster

restarting of the Pilot Arc for uninterrupted cutting.

LATCH Used for longer hand held cuts.

Onceacuttingarcisestablished,thetorchswitch

canbereleased.ThecuttingarcwillremainONuntil

thetorchisliftedawayfromtheworkpiece,thetorch

leavestheedgeoftheworkpiecethetorchswitch

isactivatedagainorifoneofthesysteminterlocks

isactivated.

3. ON OFF Power Switch

/ ON/OFFSwitchcontrolsinputpowerto

thepowersupply.UpisON,downisOFF.

4. Air/Gas Pressure Control

+

The Pressure Control is used in the "SET"

modetoadjusttheair/gaspressure.Pulltheknob

outtoadjustandpushintolock.

5. AC Indicator

Steady light indicates power supply is ready for op-

eration.Blinkinglightindicatesunitisinprotective

interlockmode.ShutunitOFF,shutOFFordiscon-

nectinputpower,correctthefault,andrestartthe

unit. Refer to Section 5 for details.

A

+

PSI BAR

MAXMAX

MINMIN

!

4

5

6

7

8

9

Art# A-07886

MIN

MAX

10

6. Temp Indicator

IndicatorisnormallyOFF. Indicator is ON when

internal temperature exceeds normal limits. Let the

unit cool before continuing operation.

7. Gas Indicator

IndicatorisONwhenminimuminputgaspressure

for power supply operation is present. Minimum

pressureforpowersupplyoperationisnotsufcient

for torch operation.

8. DC Indicator

IndicatorisONwhenDCoutputcircuitisactive.

9.

Fault Error Indicator

IndicatorisONwhenFaultcircuitisactive.Seesec-

tion 5 for explanations of fault lights.

Loading...

Loading...