ESAB CUTMASTER 80

Manual0-5396 OPERATION

4-3

A

+

PSI BAR

MAXMAX

MINMIN

!

Art# A-07946

MIN

MAX

STANDOFF

ESAB Cutmaster

®

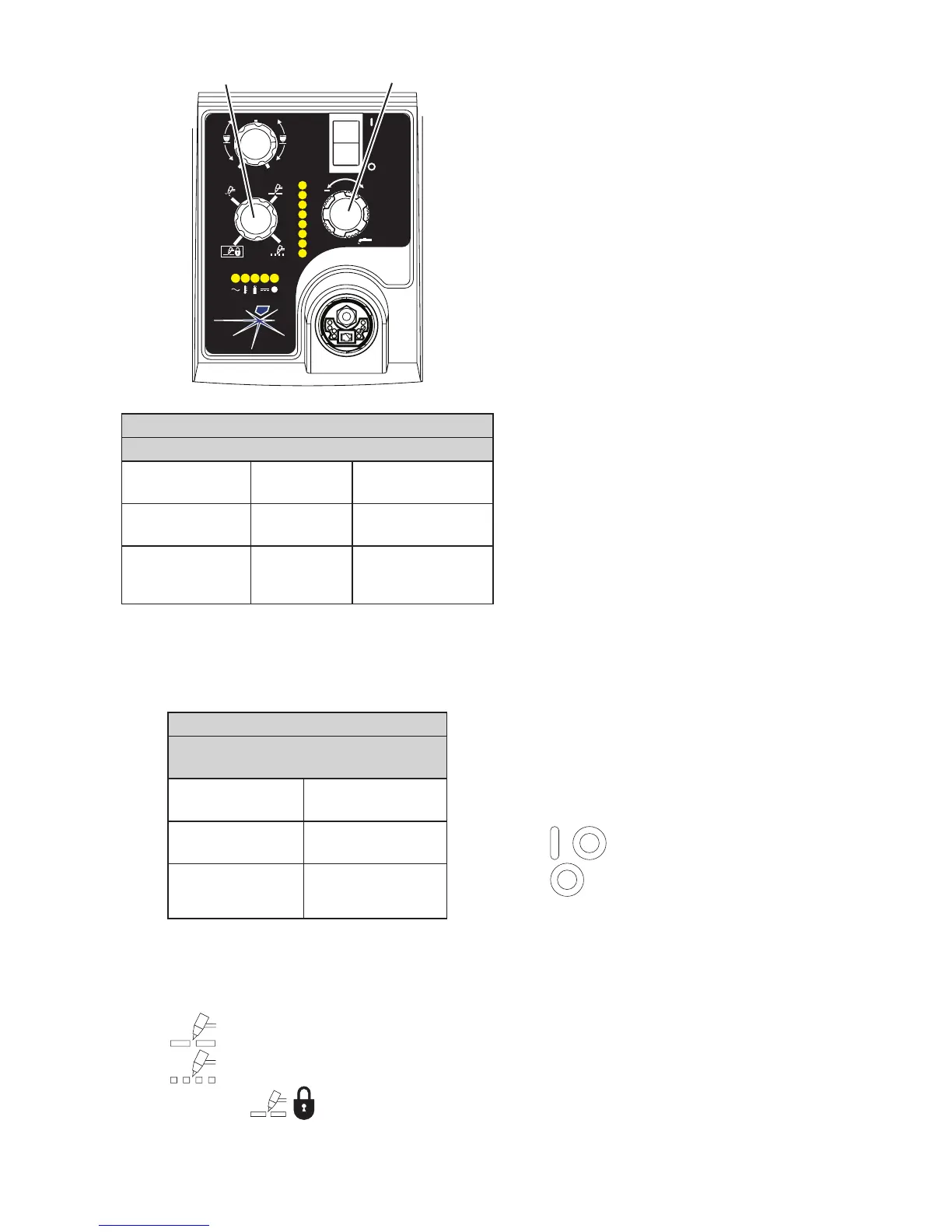

80 Gas Pressure Settings

Leads Length

SL60

(Hand Torch)

SL100

(Mechanized Torch)

Up to 25' (7.6 m)

75 psi

5.2 bar

75 psi

5.2 bar

Each additional

25' (7.6 m)

Add 5 psi 0.4

bar

Add 5 psi 0.4 bar

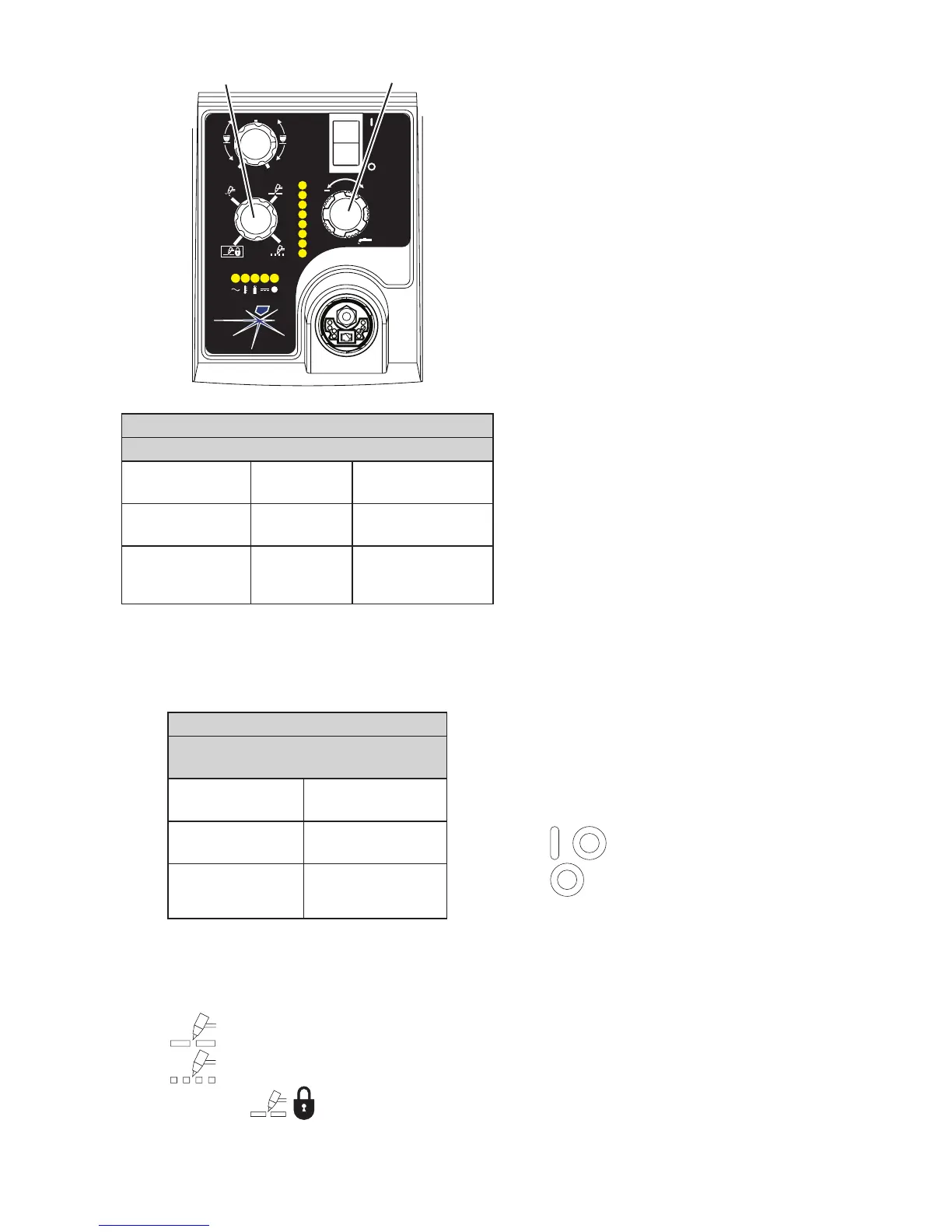

3. ForDragcutting,adjustgaspressurefrom75-

95 psi / 5.2 - 6.5 bar (LED's in center of control

panel). Refer to the Drag Cutting chart for pres-

sure setting details.

DRAG

ESAB Cutmaster

®

80 Gas Pressure

Settings

Leads Length

SL60

(Hand Torch)

Up to 25' (7.6 m)

80 psi

5.5 bar

Each additional 25'

(7.6 m)

Add 5 psi 0.4 bar

Select Current Output Level

1. Place the Function Control Knob in one of the

threeoperatingpositionsavailable:

RUN,

RAPIDAUTORESTART,

or LATCH.

Gasowstops.

2. Set the output current to desired amperage with

the Output Current Control Knob.

Cutting Operation

Whenthetorchleavestheworkpieceduringcutting

operations with the Function Control Knob in the

RUN position, there is a brief delay in restarting

the pilot arc. With the knob in the RAPID AUTO

RESTART position,whenthetorchleavesthework-

piecethepilotarcrestartsinstantly,andthecutting

arc restarts instantly when the pilot arc contacts the

workpiece. (Use the 'Rapid Auto Restart' position

whencuttingexpandedmetalorgratings,oringoug-

ing or trimming operations when an uninterrupted

restart is desired). And with the knob in the LATCH

position the main cutting arc will be maintained after

the torch switch is released.

Typical Cutting Speeds

Cuttingspeedsvaryaccordingtotorchoutputam-

perage,thetypeofmaterialbeingcut,andoperator

skill. Refer to Section 4T.08 and following for greater

details.

Output current setting or cutting speeds may be

reduced to allow slower cutting when following a

line,orusingatemplateorcuttingguidewhilestill

producing cuts of excellent quality.

Postow

Release the trigger to stop the cutting arc. Gas con-

tinuestoowforapproximately20seconds.During

post-ow,iftheusermovesthetriggerreleaseto

therearandpressesthetrigger,thepilotarcstarts.

The main arc transfers to the workpiece if the torch

tip is within transfer distance to the workpiece.

Shutdown

/ TurntheON/OFFswitchto OFF (down).

All Power Supply indicators shut OFF. Unplug

the input power cord or disconnect input power.

Powerisremovedfromthesystem.

Loading...

Loading...