42

SUMMARY

Arc voltage is a dependent variable. It is dependent upon cutting amperage, nozzle size, torch stando, cut gas

ow rate and cutting speed. An increase in arc voltage can result from a decrease in cutting speed, an increase

in cutting amperage, a decrease in nozzle size, an increase in gas ow and an increase in torch stando. Assum-

ing that all of the variables are set as recommended, torch stando becomes the most inuential variable to the

process. Good and accurate height control is a necessity in producing excellent cut quality.

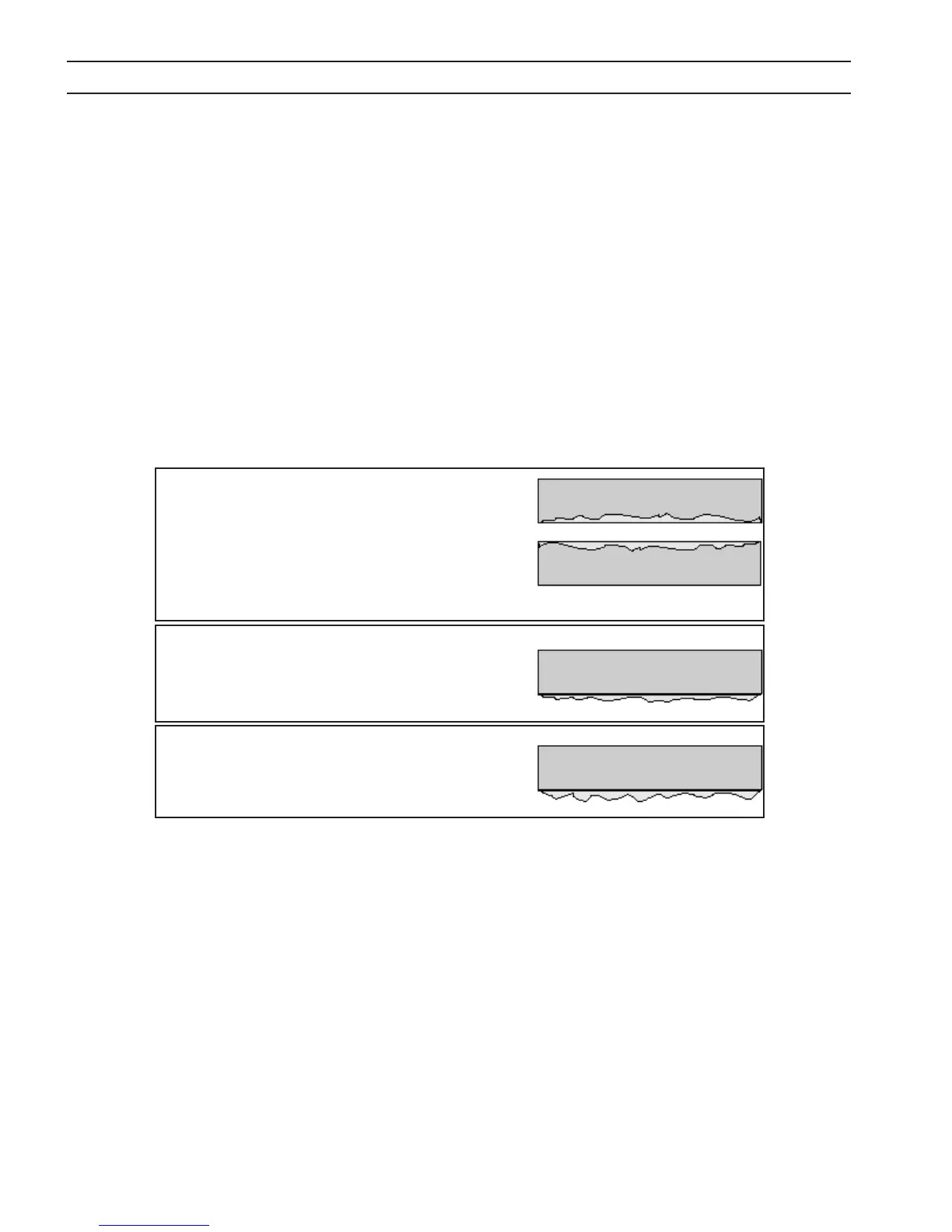

LOW SPEED DROSS

Globular dross that forms in large

deposits. Comes o very easily.

HIGH SPEED DROSS:

Fine roll over dross that welds to

bottom of edge. Cleaning requires

chipping or grinding.

TOP DROSS:

Splatter appears on the top edge of

both pieces of the plate.

Lower the voltage in increments of 5

volts DC (maximum) until top dross

disappears.

4.5 Dross Formation

Cutting speed, gas selection and variations in metal composition contribute to dross formation. The correct cut-

ting stando also has an inuence on dross formation. If the arc voltage is set too high, the cut angle becomes

positive. In addition, dross forms on the bottom edge of the part. This dross can be tenacious and require chip-

ping and grinding for removal. Setting the cutting voltage too low results in undercutting the parts or negative

cut angle. Dross formation occurs but in most cases it is easily removed.

Top Dross

Top dross usually appears as splatter near the top edge of the kerf. This is a result of torch stando (arc voltage)

set too high or cutting speed set too fast. Most operators use the parameter charts for recommended speed. The

most common problem is torch stando or arc voltage control. Simply lower the voltage settings in increments

of 5 volts until the top dross disappears. If an arc voltage control is not used, the torch can be lowered manually

until the dross disappears.

Figure 4-6. Dross Formation

SECTION 4 OPERATION

Loading...

Loading...