48

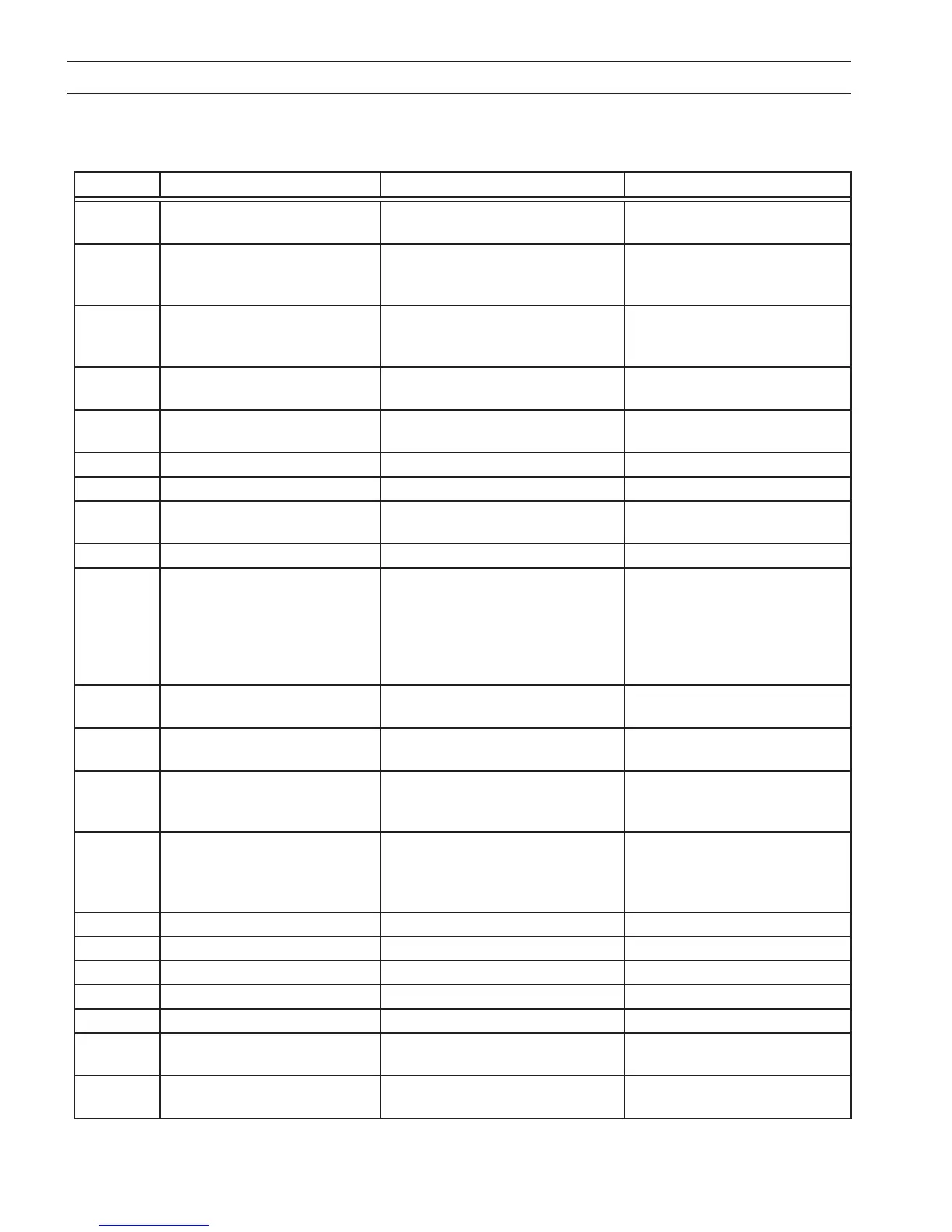

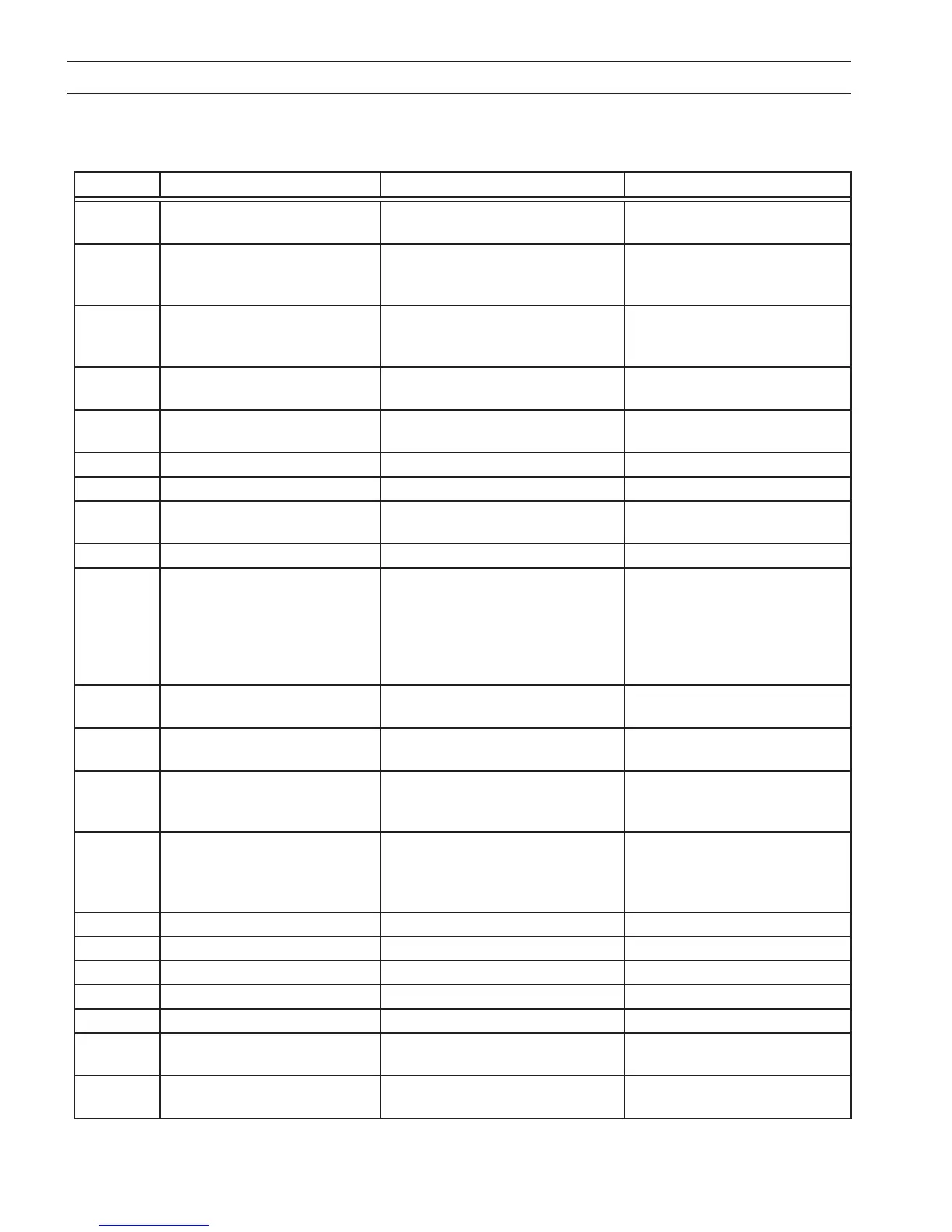

Code Error Cause Solution

1 Line voltage, idle +/- 15 % Supply line voltage either dropped

or exceeded nominal input setting.

Check voltage supply.

2 Line voltage, cutting +/- 20 % Supply line voltage either dropped

or exceeded nominal input setting

during a cut.

Check voltage supply.

3 Control bias, +/- 15 V bias split Control transformer not supplying

the proper voltage to the control

circuit

Check transformer and control

board.

4 Thermal switch Switch open - unit overheated. Allow unit to cool down, check

for adequate ventilation.

5 Pressure Air pressure is outside of proper

range.

Check air supply and pressure

setting.

6 Fail to re Arc did not transfer. Check ground cable.

7 Pilot Arc timeout (~ 5 seconds) Pilot arc exceeded 5 second limit . Start within 5 second limit.

8 Torch error Electrode in contact with nozzle

(failed to separate).

Check/replace consumables.

9

10 Feedback improper Primarily seen if Hall sensor is

unplugged.

Check torch - possible nozzle to

work short.

Remove debris from front end of

torch.

Check cable and connection

between current sensor board

and control board.

11 Primary over-current Converter failure. Send unit to an Authorized Re-

pair Station for repair.

12 Single phase operation, shut-

down

Lost (dropped) phase on the pri-

mary supply.

Check line wall disconnect fuses.

13 OCV (open circuit voltage)

failure

Voltage or current not detected

when test (parts in place, PIP) is

performed.

Send unit to an Authorized Re-

pair Station for repair.

14 Cabinet temperature Too high, outside of operating

limits.

Check ventilation around unit.

Check air louvers and any other

openings to ensure that any ob-

struction is removed.

15 Bus charger failure Primary bus not up to voltage. Check bus charger.

16

17

18

19

20 PIP (Parts in place) no retract Piston did not retract when air ap-

plied.

Check/clean consumables.

Check air supply.

21 PIP (Parts in place) no continuity Piston did not drop back in place

when air was removed.

Check/clean consumables.

6.2 List of Help Codes

SECTION 6 TROUBLESHOOTING

Loading...

Loading...