ESAB FABRICATOR 141i

OPERATION 4-10 Manual 0-5448

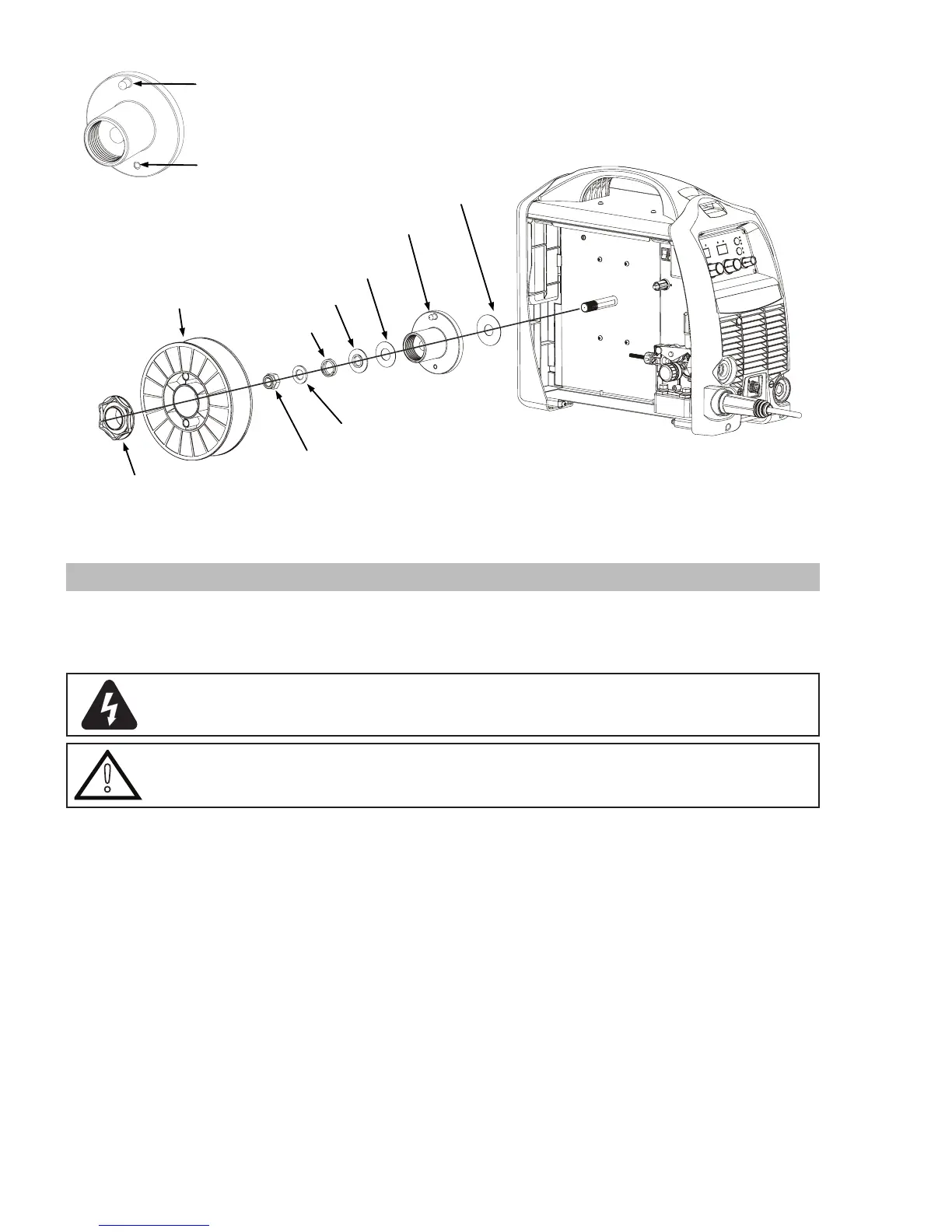

Art #

A-10358

Spring

Nut with

Nylon Insert

8” (200mm)

diameter spool

Spool Hub Nut

Alignment pin

Brass Flat

Washer

Wire Spool Hub

Friction

Washer

Plastic Spacer

Flat Washer

Alternate

Alignment Pin

Position

Figure 4-9: 8" (200mm) Diameter Spool Installation

4.06 Feed Roller Pressure Adjustment

The pressure (top) roller applies pressure to the grooved feed roller via an adjustable pressure screw. These devices should be ad-

justed to a minimum pressure that will provide satisfactory wire feed without slippage. If slipping occurs, and inspection of the wire

contact tip reveals no wear, distortion or burn back jam, the conduit liner should be checked for kinks and clogging by metal flakes

and debris. If it is not the cause of slipping, the feed roll pressure can be increased by rotating the pressure screw clockwise.

WARNING

Before changing the feed roller ensure that the Electricity Supply to the Power Source is switched off.

!

CAUTION

The use of excessive pressure may cause rapid wear of the feed rollers, shafts and bearing.

Loading...

Loading...