ESAB FABRICATOR 141i

Manual 0-5448 4-11 OPERATION

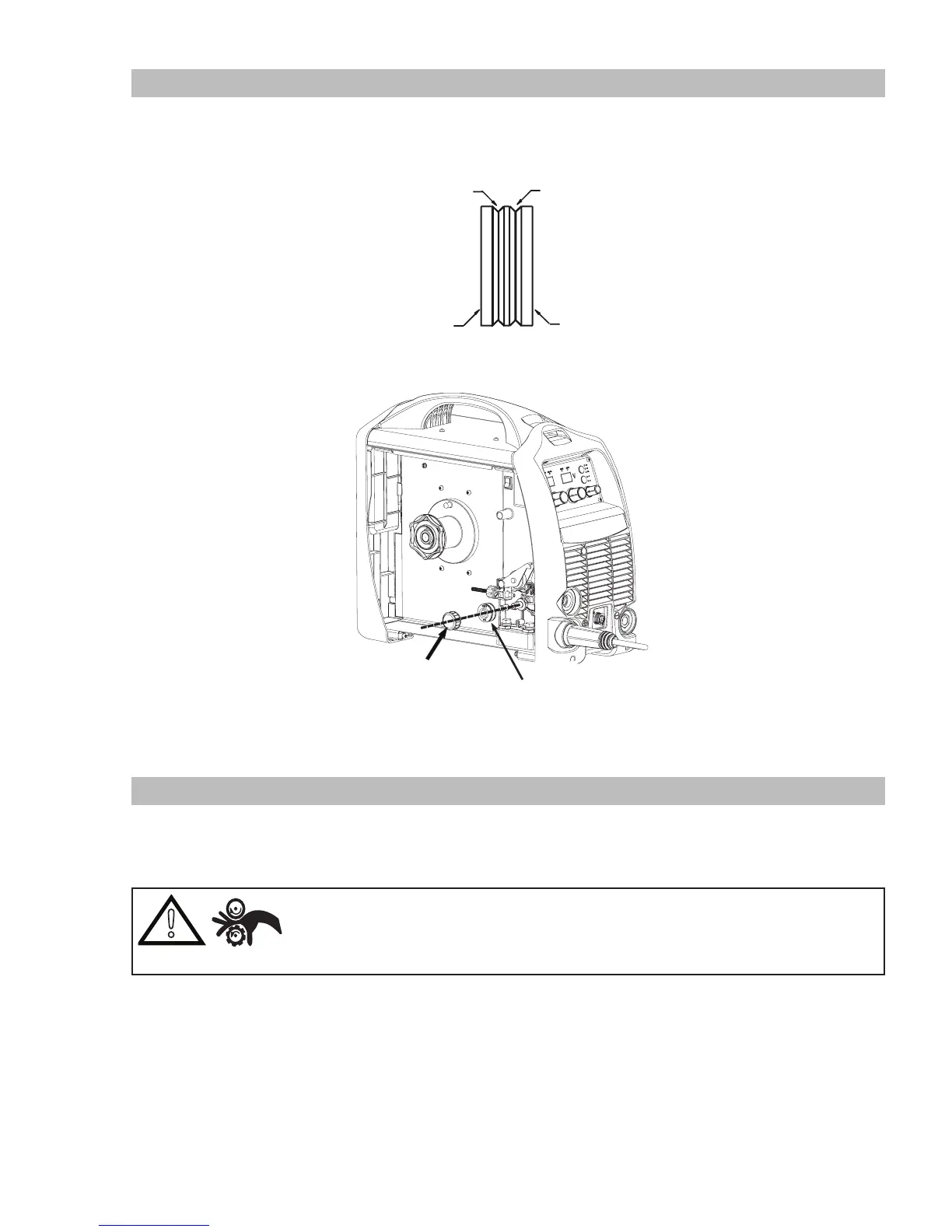

4.07 Changing the Feed Roll

To change feed roll remove the feed roll retaining screw by turning in an counterclockwise direction. Once the feed roll is removed

then to replace feed roll simply reverse these directions.

A dual groove feed roller is supplied as standard. It can accommodate 023"(0.6mm) -.030" (0.8mm) diameter hard wires. Select

the roller required with the chosen wire size marking facing outward.

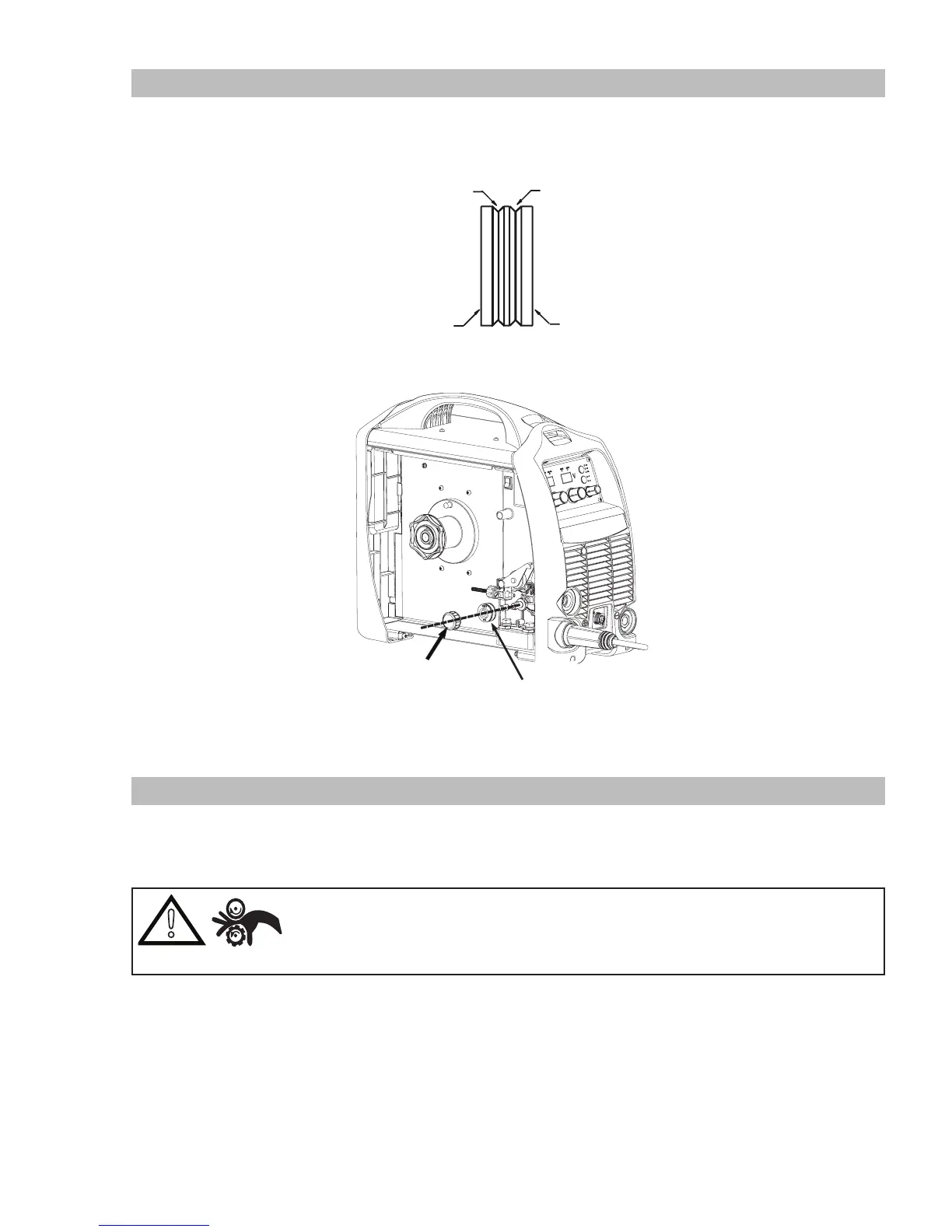

GROOVE “B”GROOVE “A”

GROOVE “A” SIZE

GROOVE “B” SIZE

A-09583

Figure 4-10: Dual Groove Feed Roller

Feed Roll

Retaining Screw

Feed Roll

Figure 4-11: Changing the Feed Roll

4.08 Wire Reel Brake

The wire reel hub incorporates a friction brake which is adjusted during manufacture for optimum breaking. If it is considered

necessary, adjustment can be made by turning the large nut inside the open end of the hub clockwise to tighten the brake. Correct

adjustment will result in the wire reel circumference continuing no further than 3/8" (10mm) - 3/4" (20mm) after release of the

trigger. The electrode wire should be slack without becoming dislodged from wire spool.

!

CAUTION

Overtension of brake will cause rapid wear of mechanical WIREFEED parts, overheating of

electrical components and possibly an increased incidence of electrode wire Burnback into

contact tip.

Loading...

Loading...