53 05 2013 4365 00

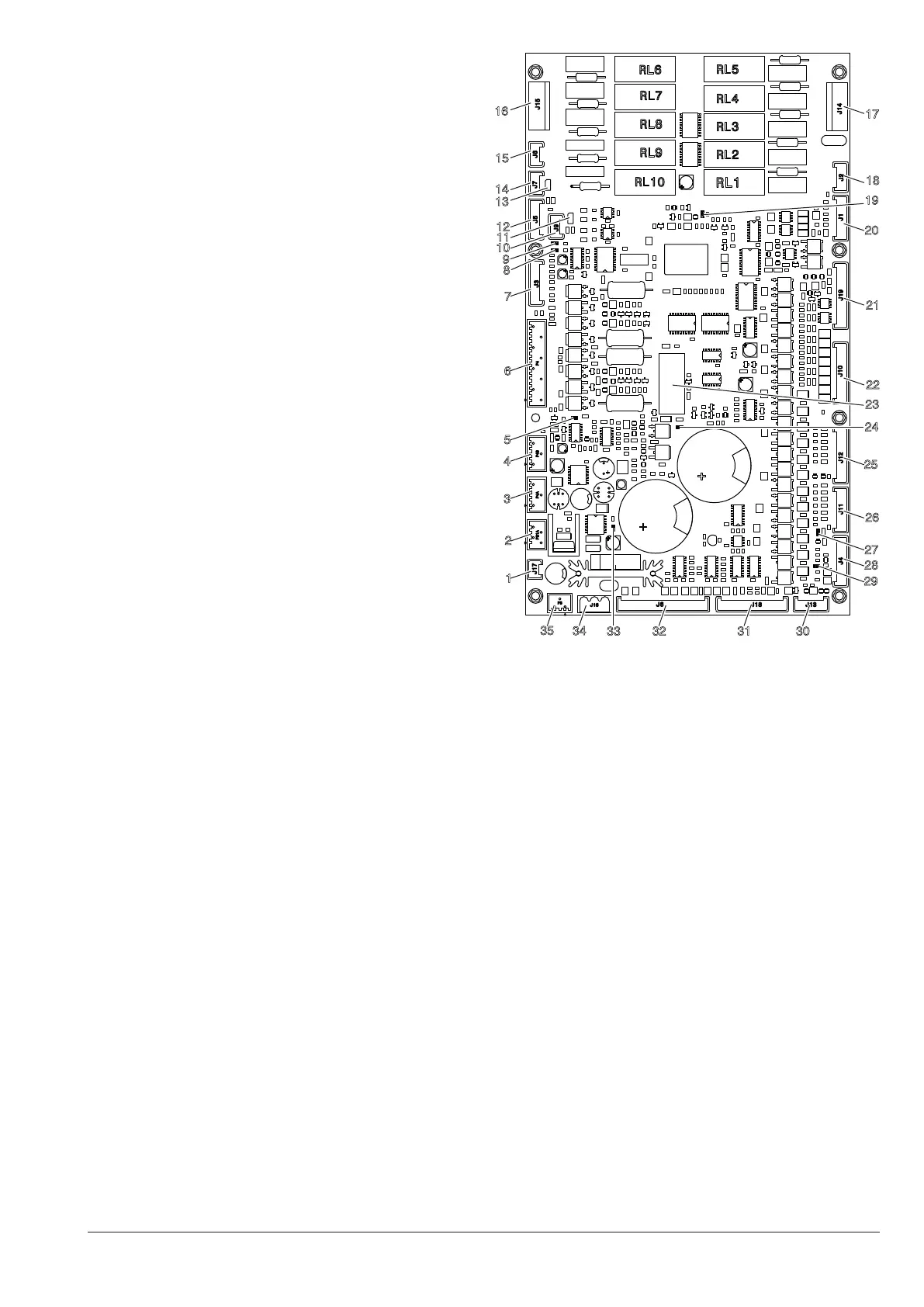

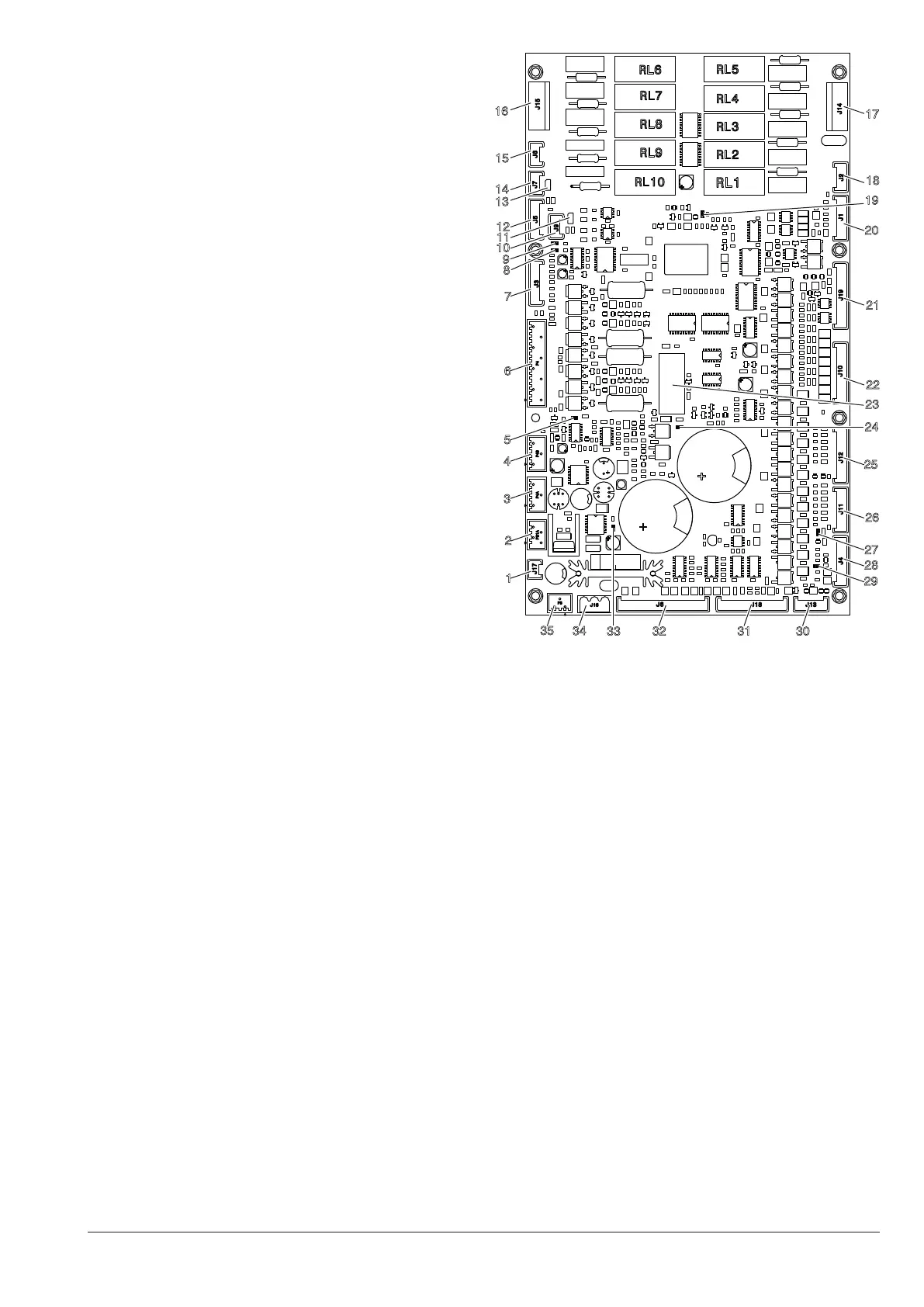

ACTIVATION BOARD

This board activates, through relays, the equipment

working and the DC motors directly. It manages the sig-

nals originating from the cams and/or microswitches on

the various equipment. Furthermore, it controls the boiler

management board. The board works with 24 Vac for the

electronic parts and the payment systems.

The board management software is loaded directly,

(through RS232) on the microprocessor.

- The green LED 3 flashes during the normal operation

of the board;

- The yellow LED 6 indicates the presence of 5 Vdc.

- The red LED 4 is on during the board reset

- The red LED 2 (not used on this model), indicates the

operating status of the instant drinks boiler resistance.

- The red LED 5 indicates the operating status of the

instant boiler resistance.

- The green LED 8 (not used on this model) indicates the

pulses of the volumetric counter.

- The green LED 5 indicates the presence of 34Vdc.

- The green LED 7 indicates the presence of regulated

34Vdc.

relay funCtion (see the Wiring diagram)

RELAY USER

RL1 = Not used

RL2 = Not used

RL3 = Not used

RL4 = Not used

RL5 = Not used

RL6 = Not used

RL7 = EEA

RL8 = Not used

RL9 = MSB

RL10 = MSCB

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

Fig. 40

1- (J17) Powder extraction

2- (P21A) 34Vdc safety relay coil and door input

3- (P4A) CPU Power supply

4- (P4B) CPU Power supply

5- Led

6- (P4) Piston motor and infuser unit brush motor

7- (J3) Not used

8- Led 2

9- Led 1

10- (J9) Not used

11- Not used

12- (J5) Probe and boiler relay

13- CAN BUS jumper

14- (J7) CAN-BUS

15- (J8) CAN-BUS

16- (J15) Users

17- (J14) Not used

18- (J2) Not used

19- Led 4

20- (J1) Not used

21- (J19) input / output 24V

22- (J10) Motor-dispensers

23- 34Vdc Safety Relay

24- Led 7

25- (J12) Mixer motors

26- (J11) Pump

27- Led 3

28- (J4) RS232 Connector

29- Led 8

30- (J13) Not used

31- (J18) Input

32- (J6) Input

33- Led 6

34- (J16) 24 Vac Power supply

35- (P8) Not used

Loading...

Loading...