55 05 2013 4365 00

BOILER MAINTENANCE

Descale the boiler at regular intervals, according to the

hardness of the mains water and the number of selec-

tions you have performed.

technical personnel only.

To descale, remove the boiler from the machine.

To descale, use biodegradable, atoxic and non-aggres-

sive products only.

Rinse abundantly before re-assembling the parts.

- Electrical contacts (terminals, faston, etc.) are perfectly

dried and well-tightened;

- Safety and anti-boil thermostats are properly positioned

and connected;

- Water connections are correct.

Important!!!

If the boiler heating system should work without water for

any reason whatsoever, check the proper operation of

the boiler temperature probe before setting the machine

at work.

If dry heating should continue until the safety thermostat

trips, the boiler temperature probe will be irreversibly

damaged and must be necessarily replaced.

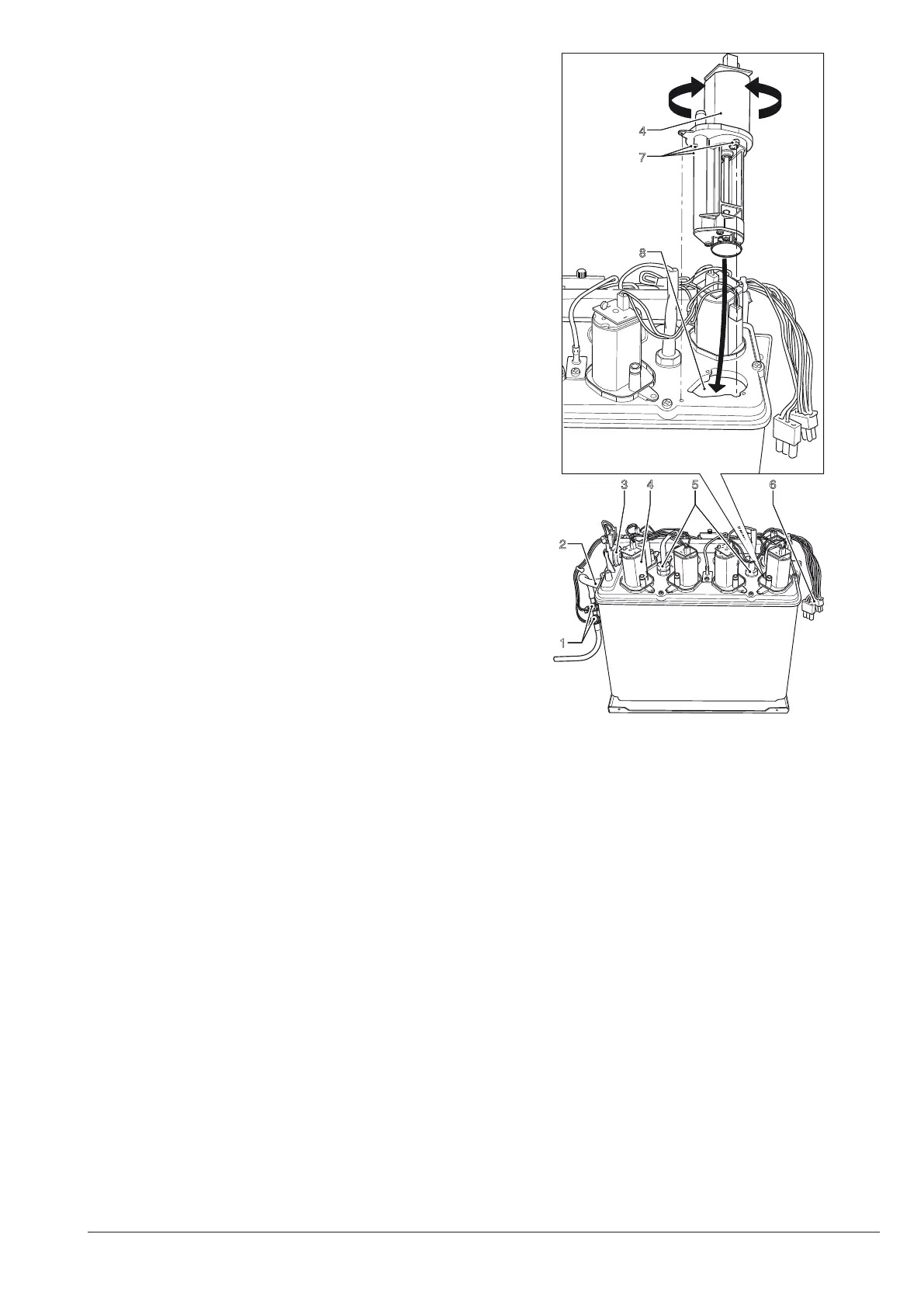

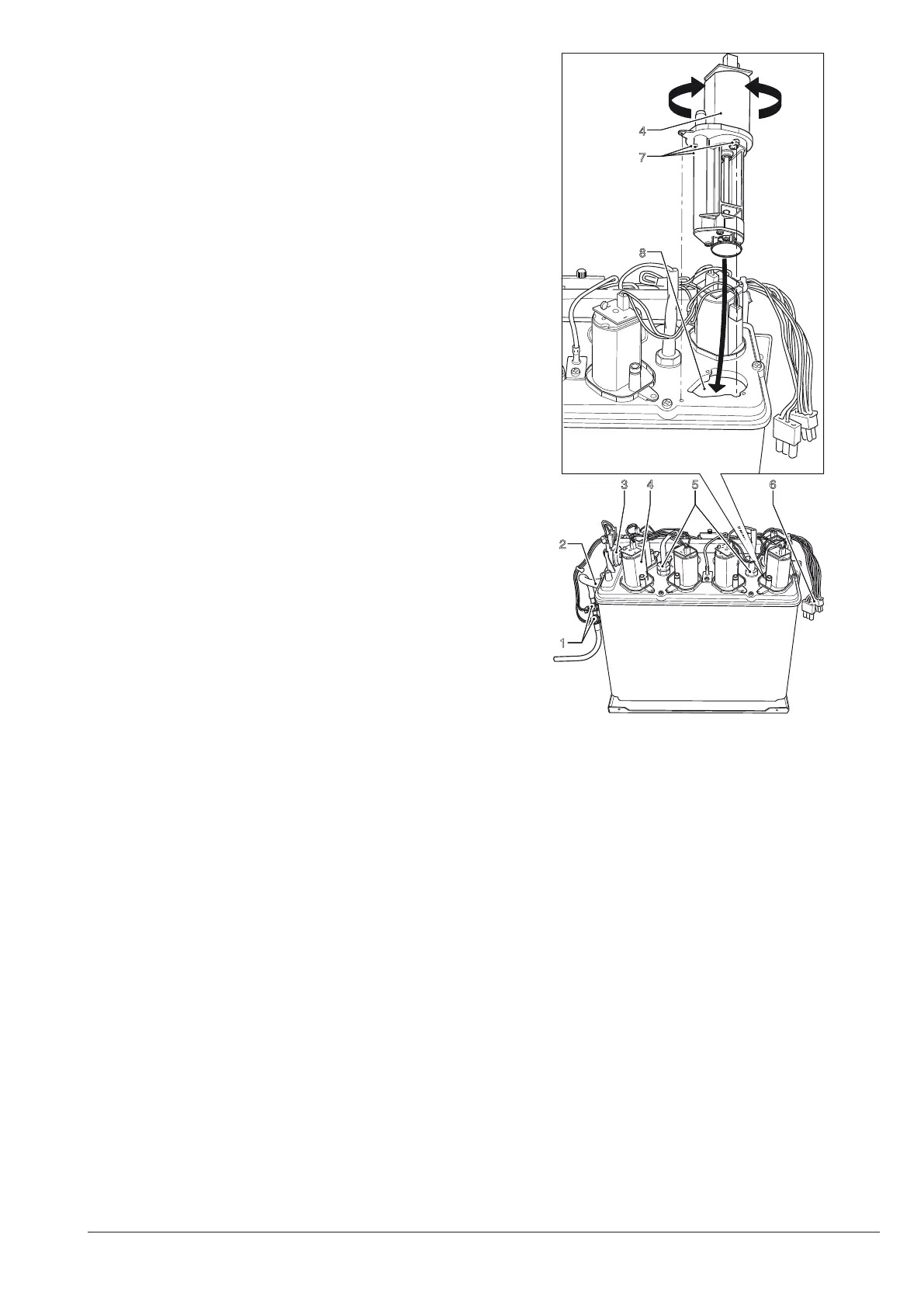

disassembling pumps

Pumps are secured to the cover by means of a bayonet

connection.

To disassemble them:

- Detach the connector

- Turn the pump for forcing slightly to overcome the snap

lock.

The direction of rotation is alternatively clockwise and

counterclockwise.

.

3 4

1

2

5 6

7

4

8

Fig. 43

1- Anti-boil thermostats (manually reset)

2- “Overflow” tube

3- Safety thermostat (manually reset)

4- Delivery pumps

5- Boiler heating element terminals

6- Electric boiler connectors

7- Bayonet connection

8- Delivery pump seat

9-

Loading...

Loading...