Functional characteristics

MIG/MAG welding

Item No.: 099-005073-EWM01 37

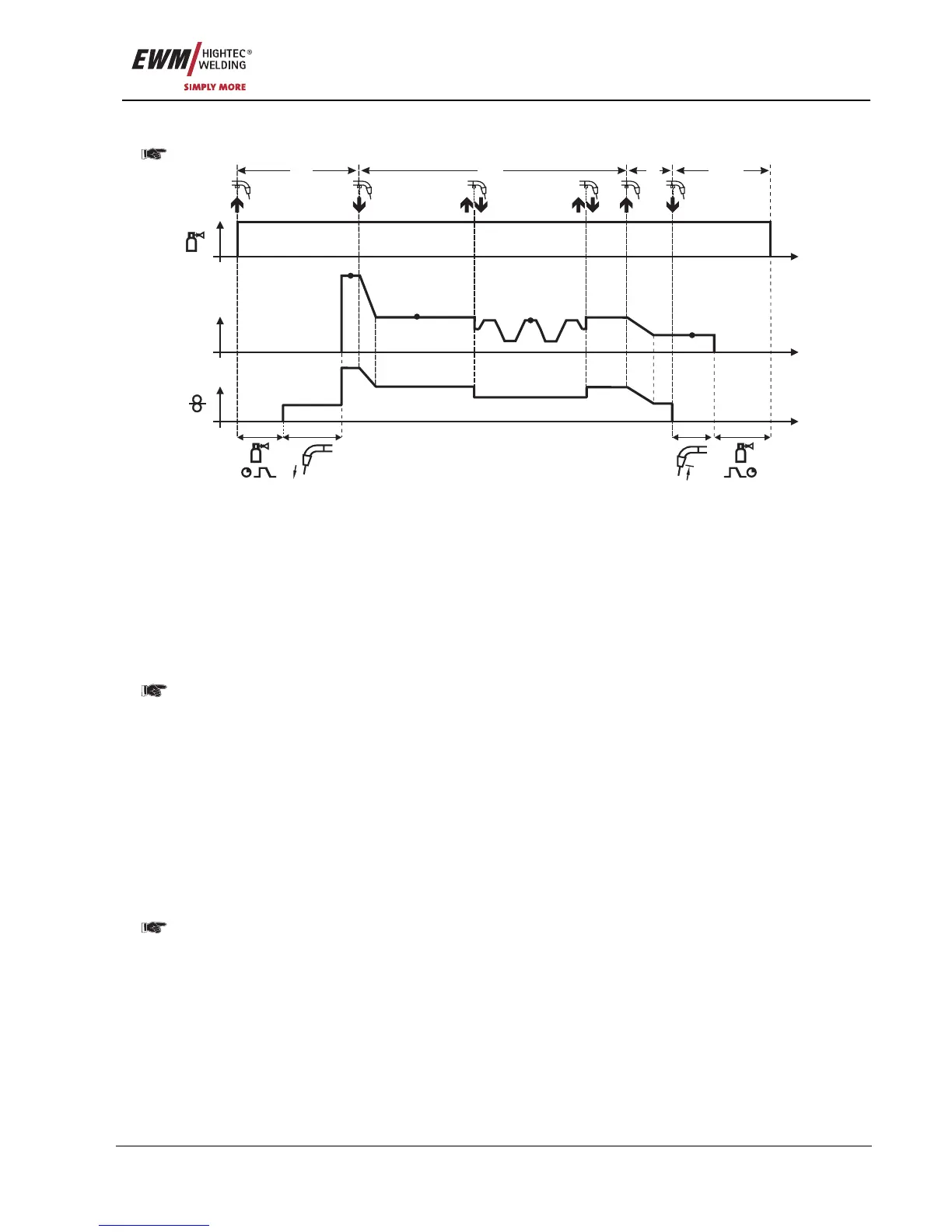

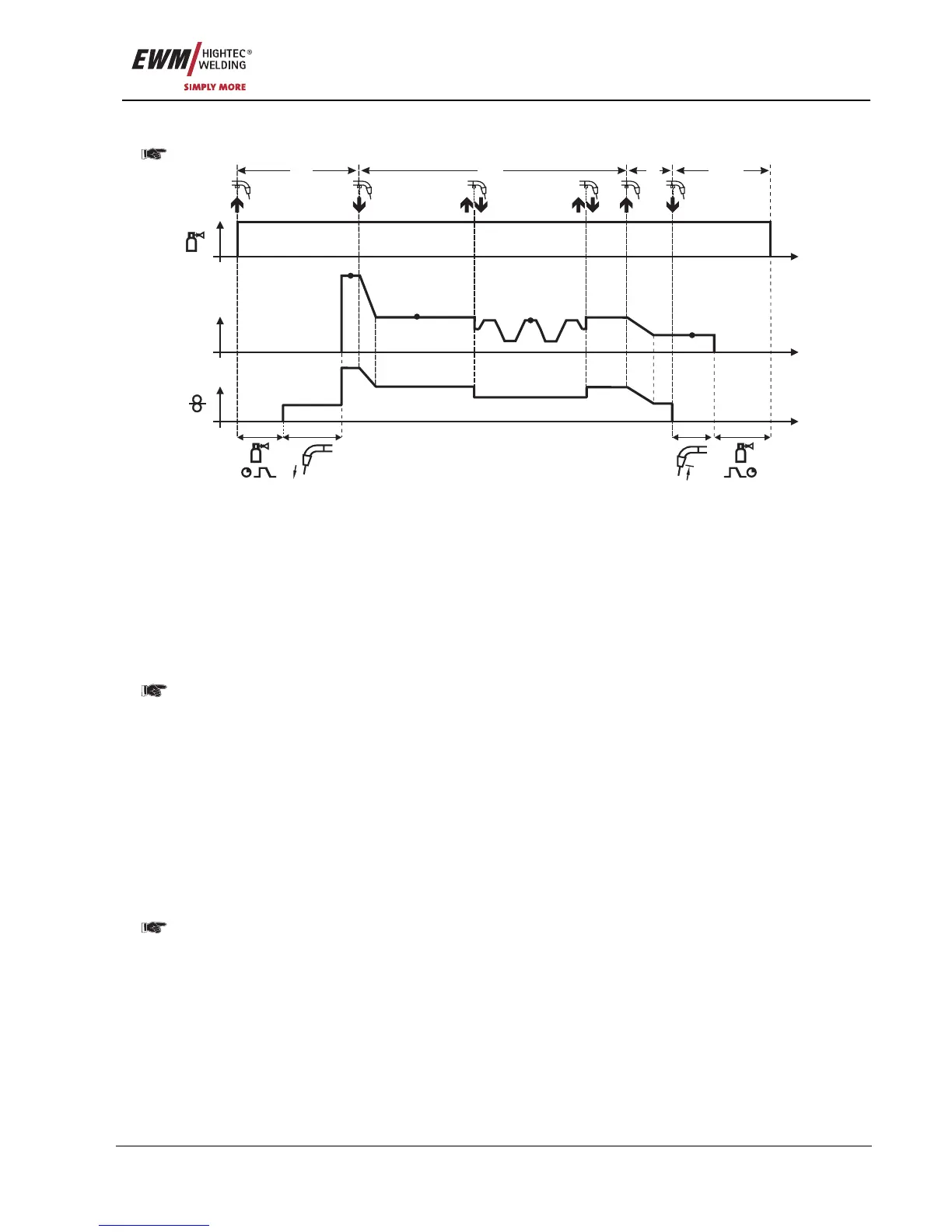

5.2.5.11 Latched special with welding process alternation

Pulse arc welding machines only.

t

t

t

I

1. 2. 3. 4.

P

A

P

B

P

END

P

START

Figure 5-14

1st cycle

• Press and hold torch trigger.

• Shielding gas is expelled (gas pre-flows)

• Wire feed motor runs at "creep speed"

• Arc ignites after the wire electrode makes contact with the workpiece, welding current is flowing (start

program P

START

)

2nd cycle

• Release torch trigger

• Slope on main program P

A

The slope on main program P

A

is given at the earliest after the set time t

START

elapses and at the

latest when the torch trigger is released.

Tapping (pressing the torch trigger for less than 0.3 sec.) changes over the welding process (P

B

).

If a standard process has been defined in the main program, tapping changes to the pulse

process, and tapping again will return to the standard process, etc.

3

rd

cycle

• Press and hold torch trigger

• Slope to end program P

END

4th cycle

• Release torch trigger

• WF motor stops

• Arc is extinguished after the pre-selected wire burn-back time elapses

• Gas post-flow time elapses

This function can be activated using the PC300.Net software.

Refer to the software operating instructions.

Loading...

Loading...