Commissioning

TIG welding

Item No.: 099-005073-EWM01 77

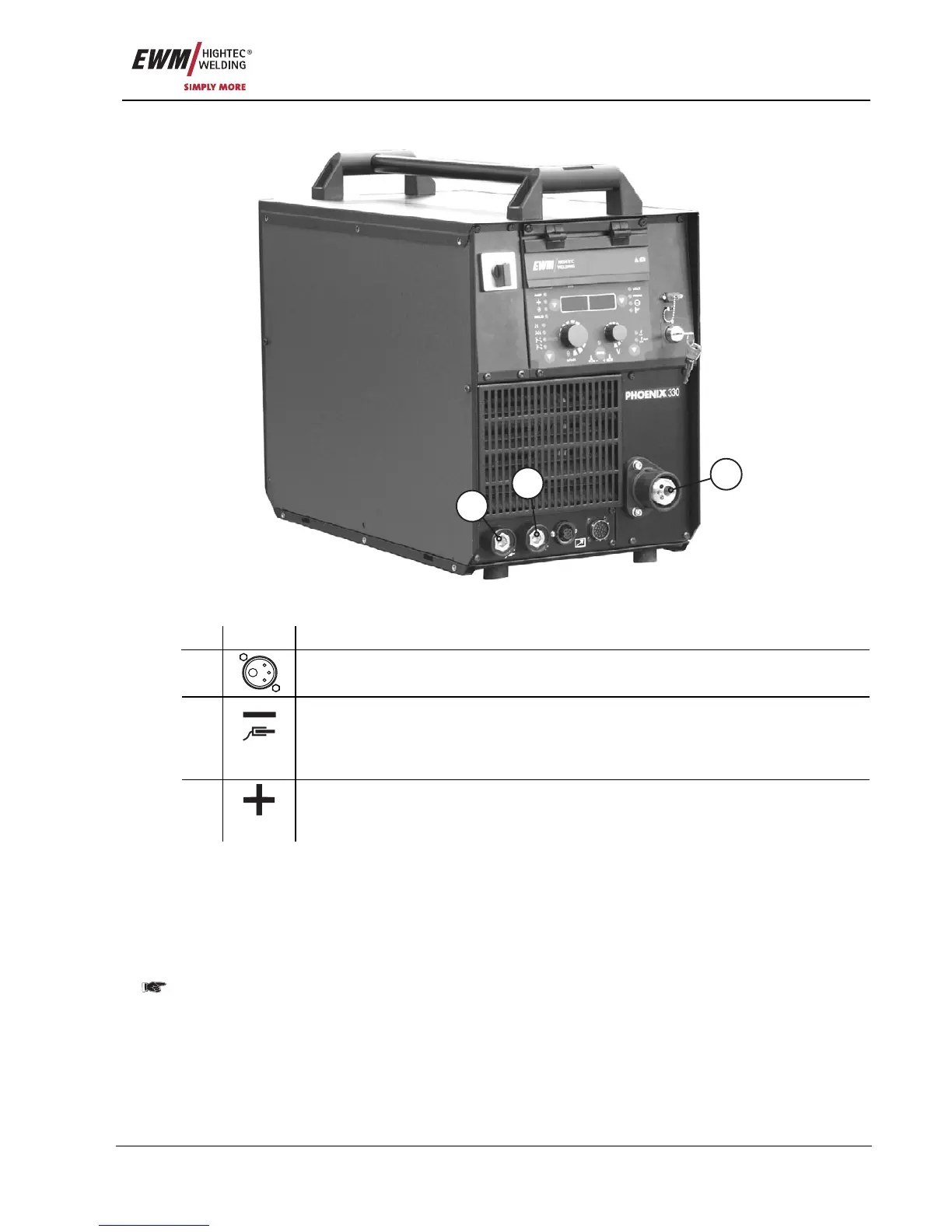

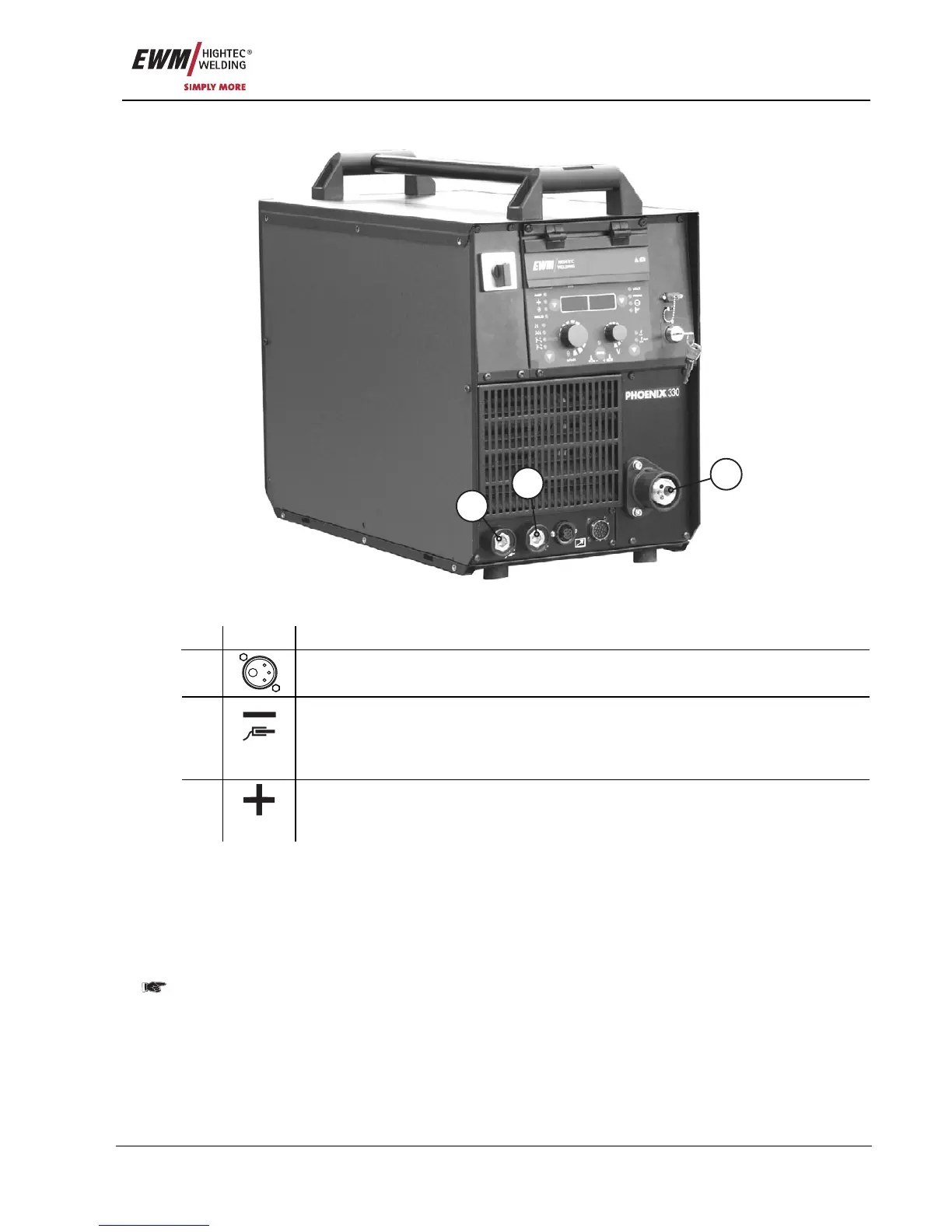

6.8.1 Welding torch connection

1

2

3

Figure 6-9

Item Symbol Description 0

1

Euro-central connector (welding torch connection)

Welding current, shielding gas and torch trigger included

Connection socket, “-” welding current

• MIG/MAG welding: Workpiece connection

• MMA welding: Workpiece or electrode holder connection

2

• TIG welding: Welding current connection for welding torch

Connection socket, “+” welding current

• MMA welding: Workpiece or electrode holder connection

3

• TIG welding: Workpiece connection

• Insert the central plug for the welding torch into the central connector and screw together with crown

nut.

• Insert central plug of the welding torch into the central connector and screw together with crown nut.

• Lock connecting nipples of the cooling water tubes into place in the corresponding rapid-action closure

couplings:

Return, red, to rapid-action closure coupling, red (coolant return) and

Return, blue, to rapid-action closure coupling, blue (coolant supply).

For the PHOENIX 330, the coolant hoses are connected directly to the cooling module.

• Insert the welding current plug on the combi torch into the “-” welding current connection socket and

lock by turning to the right.

• Insert the welding current plug on the welding torch into the welding current connection socket and

lock by turning to the right.

• Insert cable plug on the workpiece lead into the welding current socket “+” and lock by turning to the

right.

Loading...

Loading...