Functional characteristics

MIG/MAG welding

48 Item No.: 099-005073-EWM01

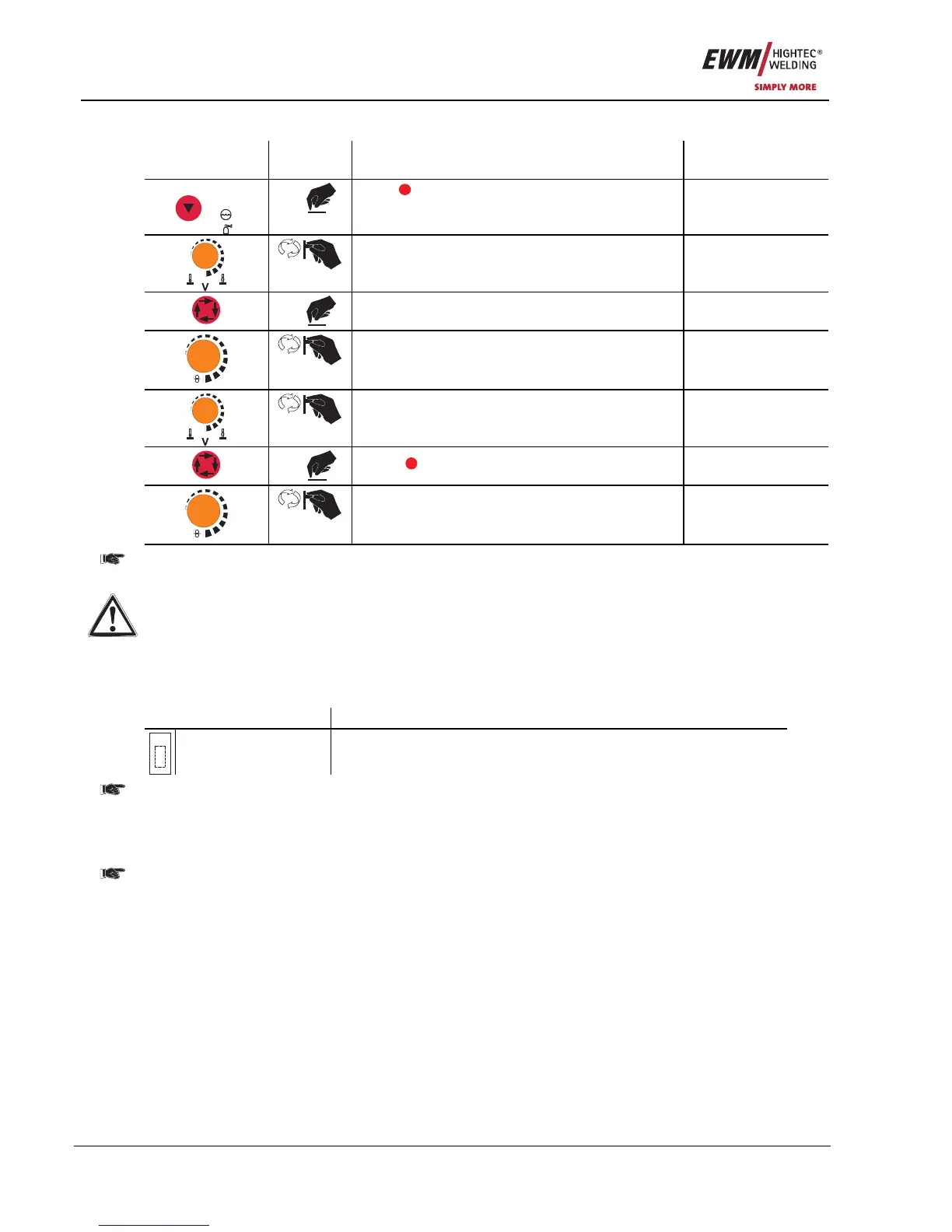

5.2.7.1 Selecting parameters (program A) using wire feed unit control M3.70

Operating

Element

Action Result Display

VOLT

PROG

x x

Press

PROG

(program number)

Select program number

x x

Select parameter LED “Main program (P

A

)”

m/min

Set wire speed

Set voltage correction

1 x

Select

DYN

Dynamics parameter

m/min

Set dynamics

Changes to the welding parameters can only be made when the key switch is in position "1".

5.2.8 MIG/MAG automatic cut-out

If pressing the torch trigger does not ignite the arc or if the arc is interrupted by the torch being

removed during the welding process, automatic cut-out occurs within 5 seconds. The welding

machine ends the welding process immediately (open circuit voltage or welding current, wire

feed and shielding gas are shut off).

5.2.9 Standard MIG/MAG torch

The MIG welding torch trigger is essentially used to start and stop the welding process.

Operating elements Functions

Torch trigger • Start/stop welding

It is also possible to change over between welding programs by tapping the torch trigger,

depending on the machine control configuration.

(see "Program changeover with standard torches (P8)" chapter)

5.2.10 MIG/MAG special-torches

Function specifications and more indepth information can be found in the operating manual for

the relevant welding torch!

The following special torches can be used together with this welding machine:

• Up/down welding torch with one rocker

− for setting the wire speed

• PowerControl welding torch with one rocker and single-digit digital display

− for calling up and displaying up to 10 welding programs, or

− for infinite, percentage-based operating point setting and display

• PowerControl 2 welding torch with four triggers and three-digit digital display

− for setting and displaying the welding performance and voltage correction, or

− for calling up programs and JOBs, as well as for displaying the corresponding parameters

• Push/pull welding torch with integrated wire feed unit

− for even wire feeding with extra long tube packages

− and potentiometer to control the wire-feed speed, where necessary

Loading...

Loading...