Functional characteristics

MIG/MAG welding

Item No.: 099-005073-EWM01 47

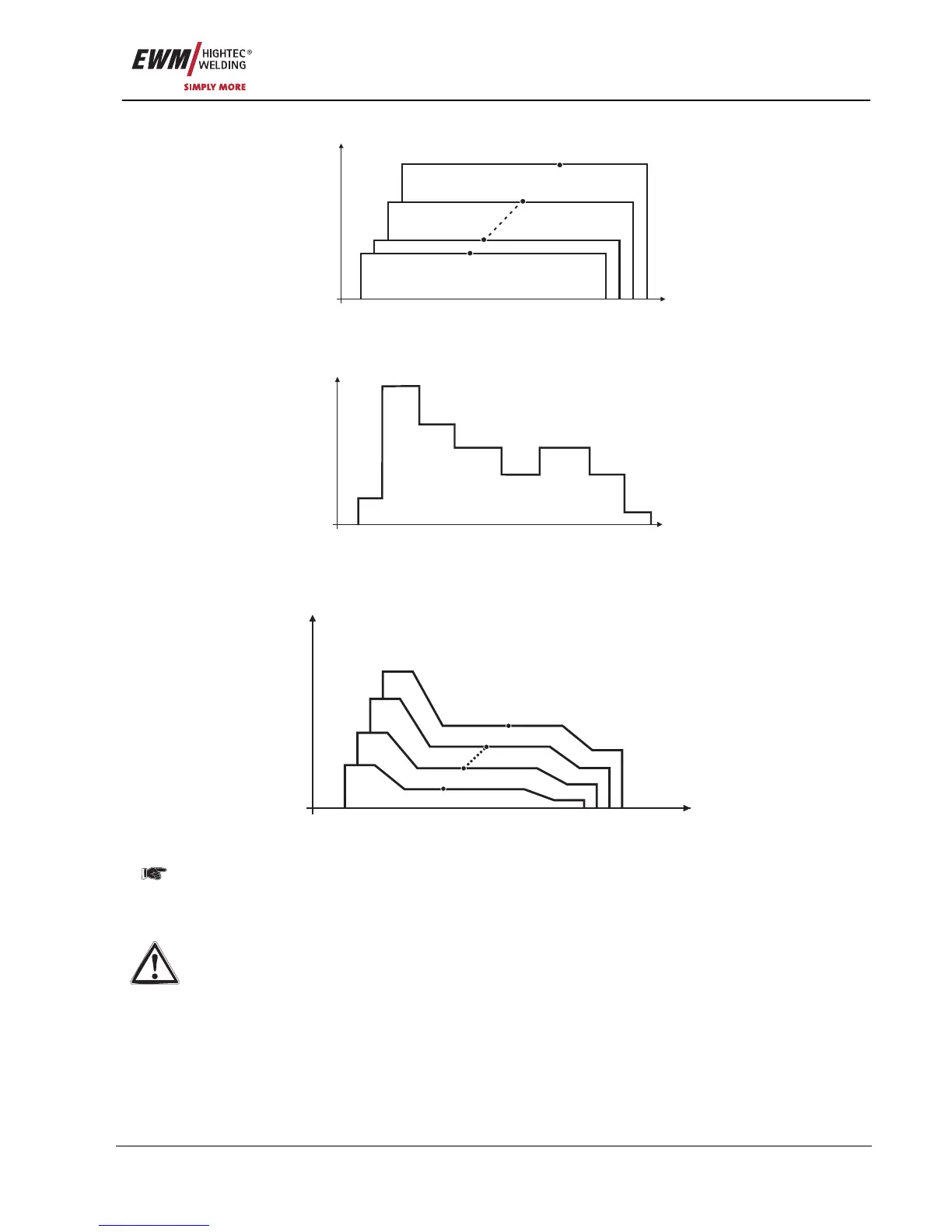

Example 1: Welding workpieces with different sheet metal thicknesses (non-latched)

t

I

P

A0

P

A1

P

A8

P

A9

Figure 5-23

Example 2: Welding different positions on a workpiece (latched)

t

I

P

A0

P

A1

P

A2

P

A4

P

A3

P

A3

P

A4

P

A5

Figure 5-24

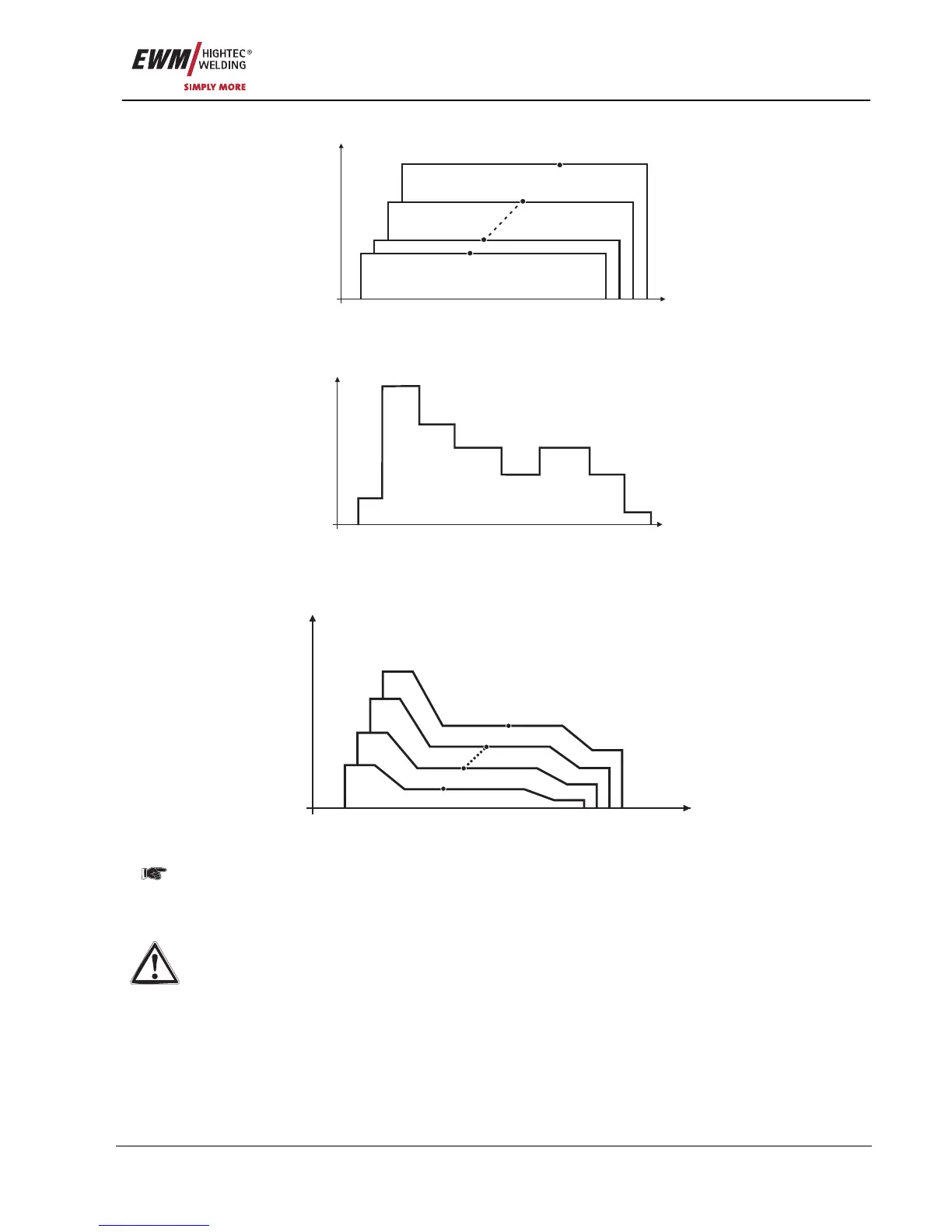

Example 3: Aluminium welding of different sheet metal thicknesses (non-latched or latched

special)

P

A0

P

A1

P

A8

P

A9

t

I

Figure 5-25

This mode can be used to define 16 different programs (P

A0

to P

A15

) for one program sequence. The

wire speed, arc length correction and dynamics/choke effect can be set for each operating point.

The following applies to program P0: The wire speed, arc length correction and dynamics/choke

effect are set using the buttons on the M3.70 wire feed controller.

Changes to the welding parameters are saved immediately!

Loading...

Loading...