Functional characteristics

MIG/MAG welding

46 Item No.: 099-005073-EWM01

5.2.7 Main program A mode

Different welding tasks or positions on a workpiece demand various welding performances (operating

points) or welding programs. The following parameters are stored in each of the up to 16 programs:

• Operating mode

• Welding type

• Superpulses (ON/OFF)

• Wire feed speed (DV2)

• Voltage correction (U2)

• Dynamics (DYN2)

P

START

, P

B

, and P

END

are factory set as “relative programs”, i.e. they are dependent on a percentage

of the WF value of main program P

A

(switching between relative and absolute wire feed values,

see chapter “WF Speed Switching (absolute / relative)”.

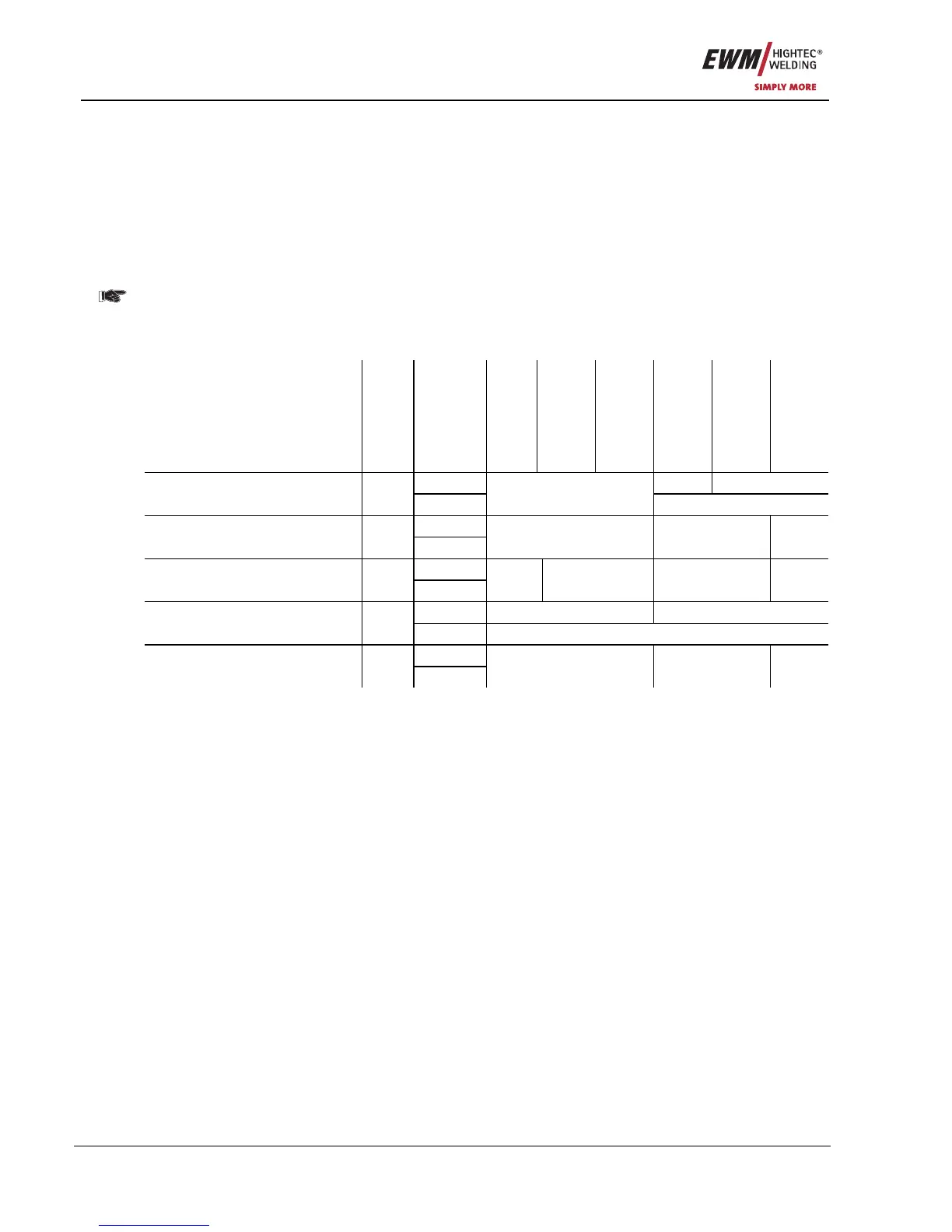

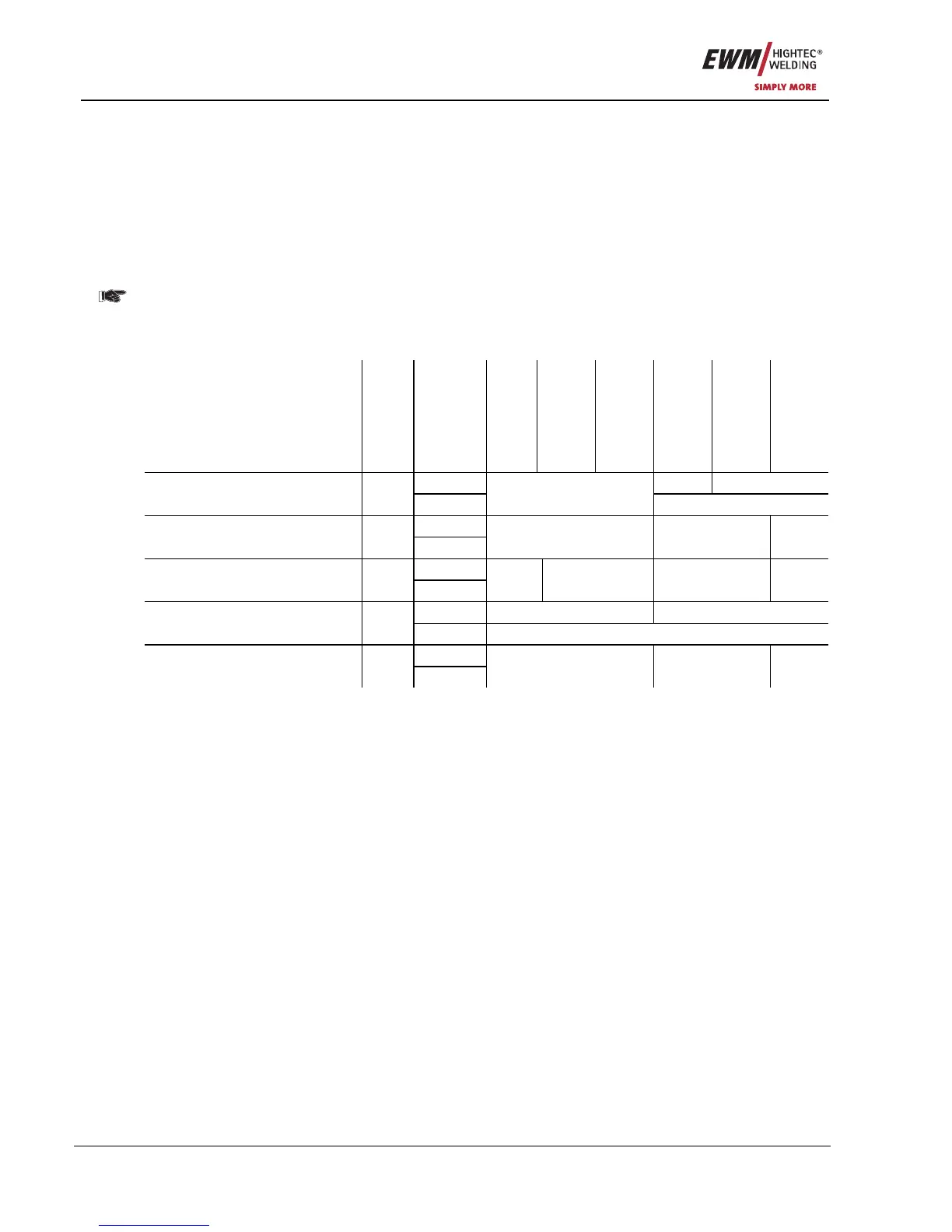

The user can change the welding parameters for the main programs using the following components.

Program

changeover

Program

Operating

mode

Welding

process

Superpulse

Wire speed

Voltage

correction

Dynamics

P0 Yes

1)

Yes

2)

M3.71

Wire feed control

Yes

P1...15

Yes

Yes

P0 R20

Remote control

Yes

3)

P1...9

No Yes

1)

No

P0 R40

Remote control

Yes

3)

P1...15

No Yes Yes

2)

No

P0 Yes No PC 300.NET

Software

No

P1...15 Yes

P0 PowerControl 2

Welding torch

Yes

P1...15

No Yes No

1) Setting carried out using rotary dial

2) Internal memory

3) Powercontrol torch not connected

Loading...

Loading...