Functional characteristics

MIG/MAG welding

44 Item No.: 099-005073-EWM01

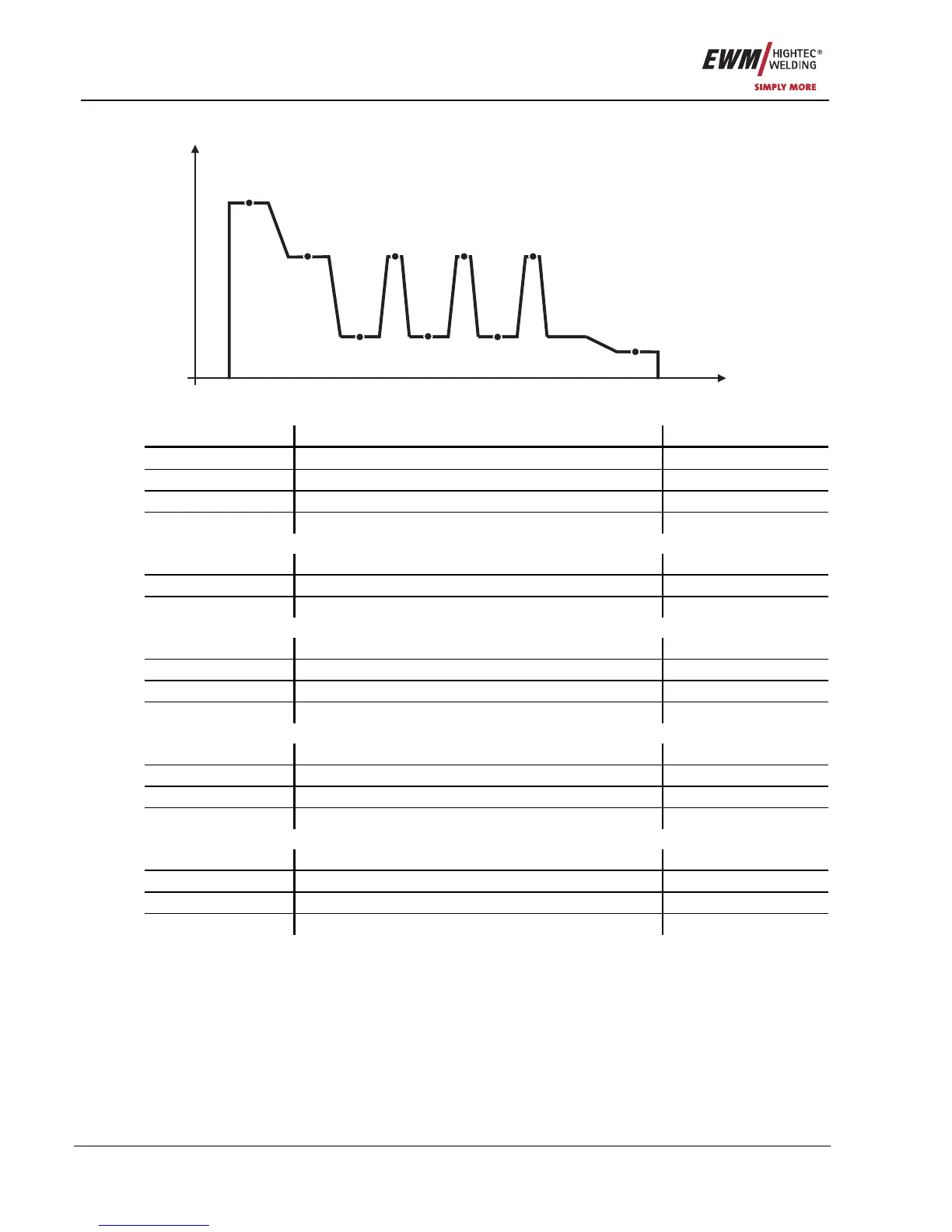

5.2.6.6 Example, visible seams (latched super pulse)

t

I

P

A

P

A

P

A

P

A

P

B

P

B

P

B

P

END

P

START

Basic parameters

Welding parameter Meaning / explanation Setting range

GASstr Gas pre-flow time 0.0s to 20.0s

GASend: Gas post-flow time 0.0s to 20.0s

RUECK Wire burn-back length 2 to 500

PROC.SP. Travel speed to determine the a-measurement* 10cm to 200cm

"P

START

" start program

DVstart Wire speed 0% to 200%

ustart Arc length correction -9.9V to +9.9V

tstart Duration 0.0s to 20s

"P

A

" main program

tS1 Slope duration from P

START

to P

A

0.0s to 20s

Setting the wire speed

t2 Duration 0.1s to 20s

tS3 Slope duration from P

B

to P

A

0.0s to 20s

"P

B

" reduced main program

tS2 Slope duration from P

A

to P

B

0.0s to 20s

DV3 Wire speed 0% to 200%

U3 Arc length correction -9.9V to +9.9V

t3 Duration 0.1s to 20s

"P

END

" end-crater program

tSend Slope duration from P

A

or P

B

to P

END

0.0s to 20s

DVend Wire speed 0% to 200%

Uend Arc length correction -9.9V to +9.9V

tend Duration 0.0s to 20s

Loading...

Loading...