73

© Ferno s.r.l. Rel.05042024

XT Series Extrication Devices

WARNING

The following instructions should only be followed

if the textile ring (EN 795/B) is the one supplied by

Ferno. If a device from another manufacturer is

used, the manufacturer's instructions must be used

(EN 365).

- When it becomes obsolete (new laws, standards, techniques

or incompatibility with other devices).

Avoid any contact with chemical substances, especially

acids that can destroy bres.

7.1.3 XT Floating Maintenance

INSPECTION BEFORE USE

To ensure optimal use of the device, it is important to keep

all the components in good conditions and to remove all

traces of dirt, debris and body uids. The XT Floating must

be inspected before and after each use, and must be cleaned

after use. When not in use, it must be stored in a dry, indoor

environment and inspected at least once a month. If the

inspection reveals cracks on the board, deep scratches or

wear signs on textile components, place the device out of

service and contact Ferno's technical support.

PREVENTIVE INSPECTION

The XT Floating is a medical device requiring regular

maintenance. Preventive inspections are the responsibility

of the user. It is recommended to use the checklist in this

manual and to report the check in the appropriate registration

table.

PERIODIC MAINTENANCE

It is recommended that the XT undergo a complete product

overhaul and certication by Ferno personnel once a year

from the 10th year after purchase.

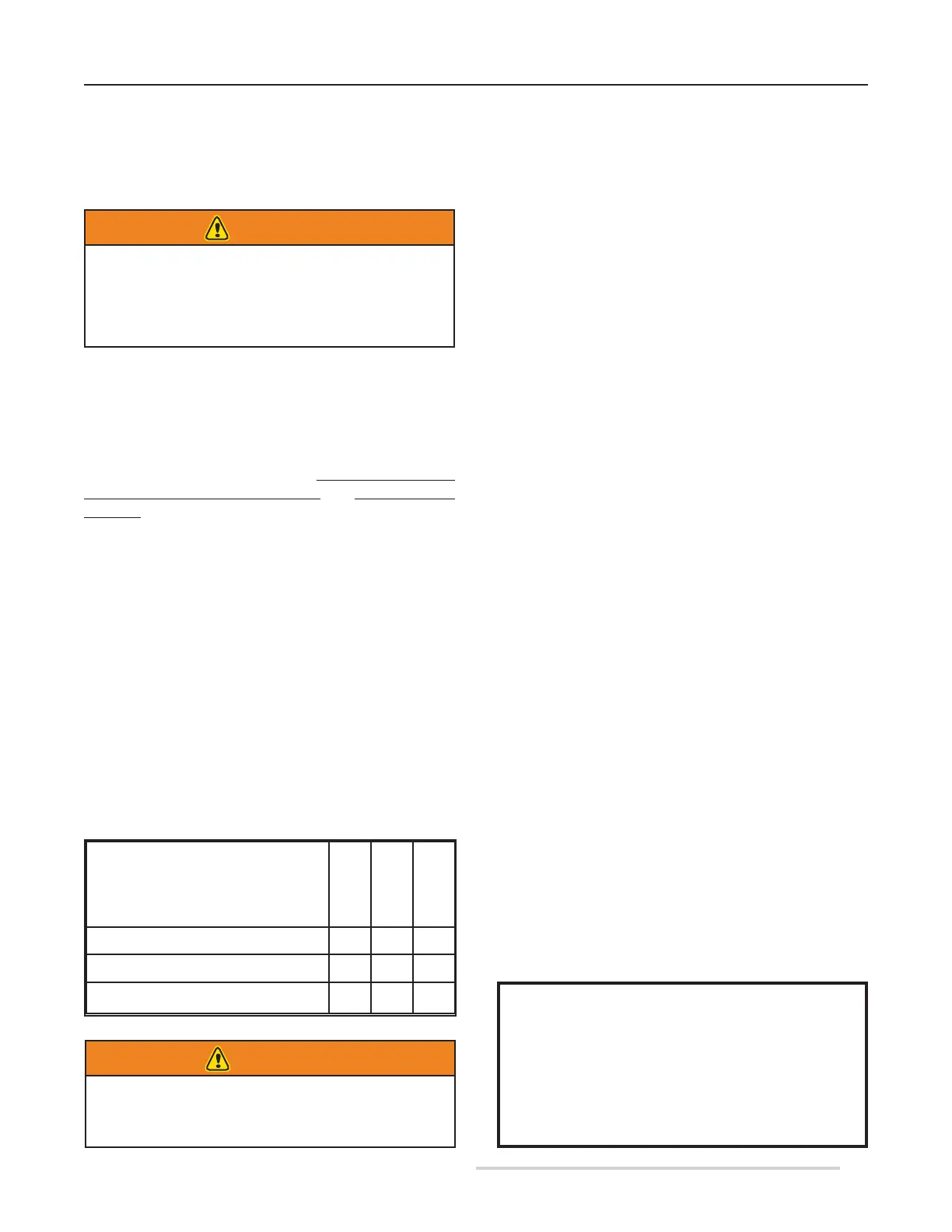

Preventive maintenance

intervals

After each

use

Whenever

necessary

Every

month

Disinfection

• •

Cleaning

• •

Inspection

• • •

EXTRAORDINARY MAINTENANCE

Whenever, during the inspection, user nds cracks on the

board, deep scratches or obvious signs of wear on the textile

material, it is recommended to contact Ferno's Technical

Support Department to have the XT completely overhauled

and certied by Ferno's authorised personnel. See chapter

Technical Support.

If the XT undergoes particularly heavy use, if it is used

in an environment contaminated by hazardous chemical

substances or for carrying heavy loads, maintenance and

overhaul should preferably be carried out on a more frequent

basis.

Important

Ferno directly carries out repair maintenance

operations, without the need of dealers, mechanics

or external service centres (if not recommended by

the manufacturer). You are thus invited to be wary of

those who present themselves as Ferno's authorised

technician without providing further information.

WARNING

Improper maintenance may cause serious accidents

and/or damage. Perform maintenance as instructed

in this user manual.

TEXTILE MATERIAL RESTRAINTS AND FLOATS

Check along the entire length of the device that:

- All textile parts and stitching on the device are free from

cuts, abrasion, frayed borders, wear, corrosion, burns and

signs of chemical substances; also check that the stitching is

not cut, frayed or loose.

- Check, by feeling the entire length of the devices made of

textile material with your ngers.

- Ensure the integrity of the stitching protective cover (no

movements or detachments from its terminal).

- Before use, also check that the maintenance sheets of each

device are correctly updated.

During each use:

- Regularly check the proper functioning of the product and

the optimal connection and arrangement of the other system

components.

- Pay attention to the effects of moisture and frost, as these

could compromise the tightness of the device.

- Beware of contact with sharp edges and, if necessary,

recheck the device after use.

As far as the textile material is concerned, the

MAXIMUM useful life is considered to be equal to 10

years from its rst use, so it must be replaced after this

period of time.

The product must be disposed of:

- After 10 years, if it includes plastic or textile components.

- After a strong effort.

- If the result of the product checks is not satisfactory and

one has doubts about its reliability.

Loading...

Loading...