A. Technical appendix

A-8

Festo P.BE-CB-COMP-EN en 1102d

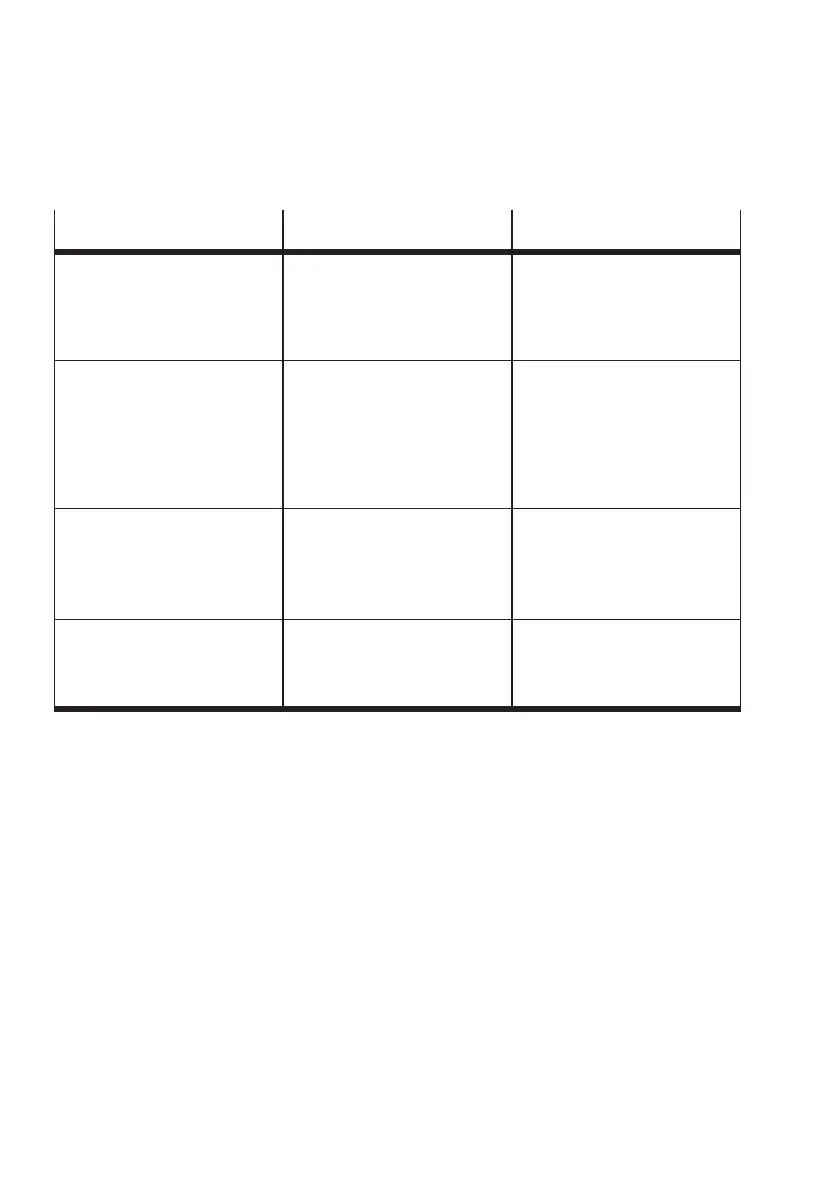

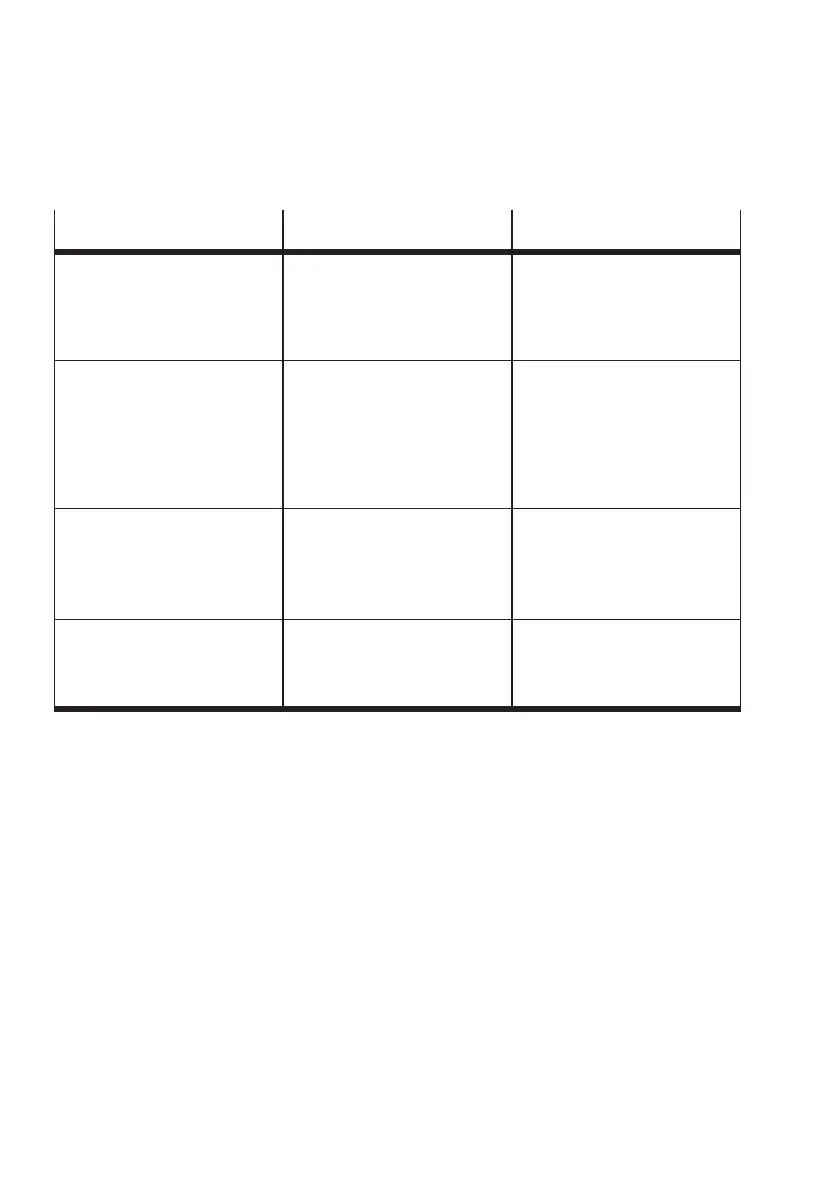

Error status Cause Action

...Full, although the buffer zone

is not full.

Good parts in all orientations

are blown back into the small

parts conveyor .

– Control line is defective or

incorrect pin assignment at

the BUFFER/FEEDER

connection.

– Incorrect sensor type is set.

– Make sure that circuitry is

correct at the

BUFFER/FEEDER connection.

–WithCheckKon:Change

sensor type.

...E 02, although conveyed par t

length is shorter than maximum

length permitted.

– Conveyed part has a lot of

holes or semi-transparent

conveyed par t

– Conveyor speed has been

changed.

With CheckKon:

– Increase conveyor speed.

– Increase exposure time,

division factor

– Vary the grey-value threshold

– Limit field of vision of camera

– Activate filter function.

...E 02 appears in the morning

although the Checkbox

functioned faultlessly the day

before.

– High fluctuations in

temperature e.g. between

day and night

– Conveyor device has been

replaced.

– With CheckKon: Set the

picture limits.

...E 04, although only a low

number of bad parts has

passed the test procedure.

Moveable dirt particles on the

conveyor device.

– Clean the conveyor device

with compressed air.

– Install a separator device in

front of the c onveyor device.

Tab. A/3: Other fault states

Loading...

Loading...