Page 2 of 12 TOTALPAC2

TOTALPAC2 Integrated Fire Protection Systems

Mechanical Section - Deluge System

FM-086G-0-24D

1.3 Placing the system in service:

(Refer to MECHANICAL TRIM DESCRIPTION and TRIM

SCHEMATIC)

1. Verify the following:

a) The system Main Water Supply Control Valve (D1) is

CLOSED.

b) The system has been properly drained.

c) Flow Test Valve (B6) is OPEN.

d) The Emergency Release Valve (B10) is CLOSED.

e) The system water supply piping is pressurized up to

the CLOSED Main Water Supply Valve (D1) and the

priming line is pressurized up to the CLOSED

Priming Valve (B1).

2. Verify that all releasing devices are set and that any

Inspector's test Valve and/or auxiliary drain valves are

CLOSED.

a) OPEN Priming Valve (B1).

3. OPEN Main Drain Valve (D3).

4. PARTIALLY OPEN Main Water Supply Control Valve

(D1).

5. When full flow develops from the Flow Test Valve (B6),

CLOSE the Flow Test Valve.

a) Verify that there is no flow from the open Main Drain

Valve (D3).

6. CLOSE Main Drain Valve (D3).

7. FULLY OPEN and secure the Main Water Supply

Control Valve (D1).

8. Verify that the Alarm Test Valve (B5) is CLOSED and

that all other valves are in their "normal" operating

position (Refer to TRIM SCHEMATIC for details).

9. Depress the plunger of the Drip Check Valve (B7). No

water should flow from the Drip Check when the plunger

is pushed.

10. Check and repair any leaks.

11. On new installations, systems that have been placed out

of service, or where new equipment has been installed,

trip test system to verify that all equipment functions

properly. Refer to MAINTENANCE – ANNUALLY for

instructions.

CAUTION ! Performing a trip test results in operation of the

Deluge/Flow Control Valve. Water will flow into the

sprinkler piping. Take necessary precautions to prevent

damage.

12. After completing the trip test, perform MAINTENANCE –

SEMI-ANNUALLY.

Note: When a valve has been removed from service and is

subject to freezing or will be out of service for an extended

period of time, all water must be removed from the priming

chamber, trim piping, water supply piping and any other

trapped areas.

13. Notify the Authority Having Jurisdiction, remote station

alarm monitors, and those in the affected area that the

system is in service.

Important Settings

Release Piping Pressures.

f Deluge Systems with Pneumatic Release

(also refer to Table 1 below):

.a Provide a minimum 30 PSI (207 kPA) pneumatic

pressure to the pneumatic release system and

Pneumatic Actuator (F3) for system water pressures of

175 psi (1 207 kPa) or less.

.b For system water pressures above 175 psi (1 207 kPa)

and up to 250 psi (1 724 kPa), provide a minimum of 50

psi (345 kPa) pneumatic pressure to the pneumatic

release system and Pneumatic Actuator (F3).

.c Set release system Air Pressure Supervisory Switch

(E3) to activate at 25 psi (172 kPa) on pressure drop for

system water pressures of 175 psi (1 207 kPa) or less.

For system water pressure above 175 psi up to a

maximum of 250 psi (1 724 kPa), set the Air Pressure

Supervisory Switch (E4) to activate at 45 psi (310 kPa)

on pressure drop. Air Pressure Supervisory Switch

(E4) is factory wired to activate an alarm to signal a low

air pressure condition (see AIR OPTION SECTION for

additional details).

Note: The air supply for the pneumatic release piping

system must be provided by the contractor and installed

outside the TOTALPAC2 unit. The air supply must be

restricted to ensure that the automatic air supply cannot

replace air as fast as it escapes when a releasing device or

sprinkler operates. It is also recommended to provide

Inspectors Test Connections on the release system.

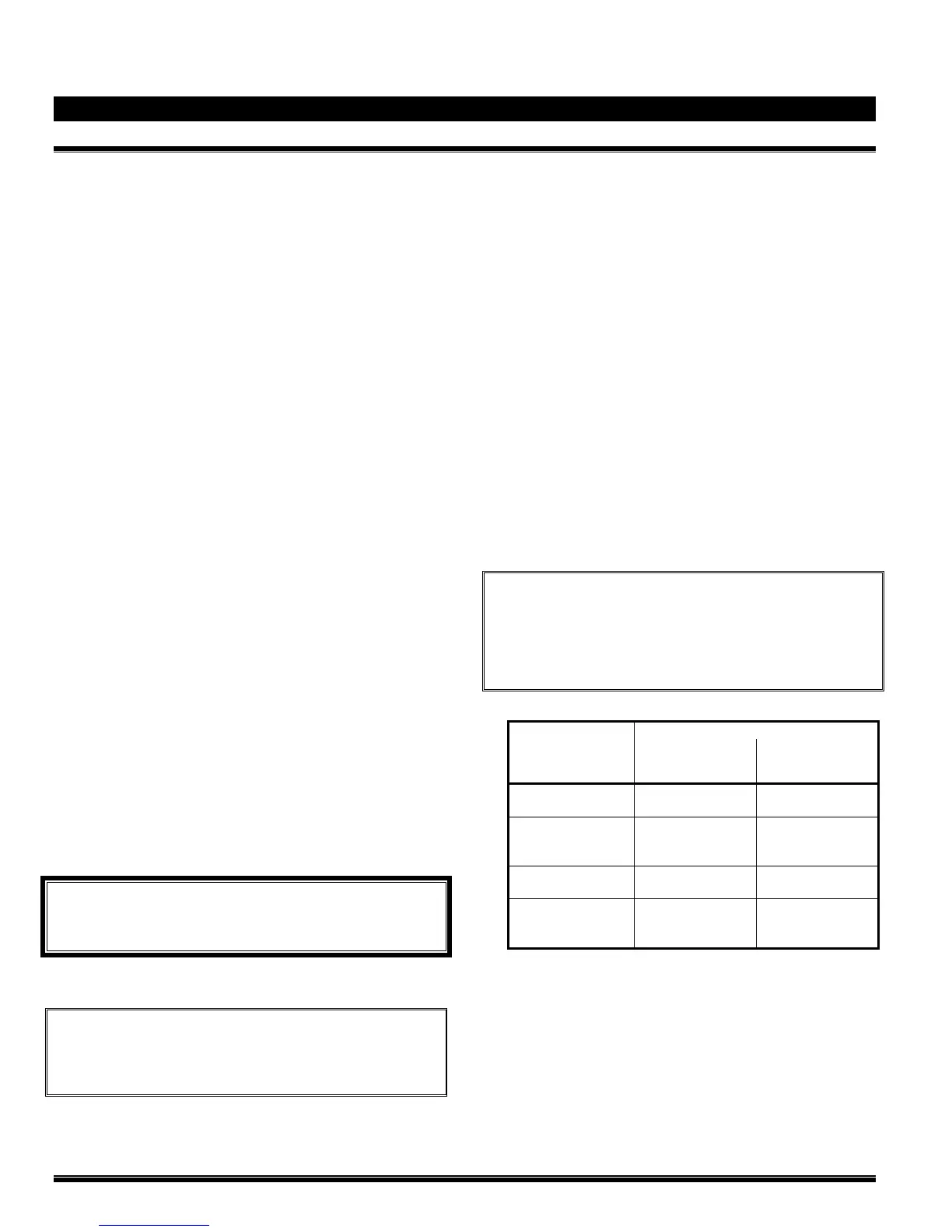

Table 1: Settings for Pneumatic Release Systems.

WATER SUPPLY PRESSURES

DEVICE

Up to 175 psi

(1 207 kPa)

SET TO MAINTAIN

175 psi (1 207 kPa)

to 250 psi (1724 kPa)

SET TO MAINTAIN

Air Maintenance

Device (E5)

30 PSI (207 kPa) 50 PSI (345 kPa)

Release System

Pressure Supervisory

Switch (E4)

25 PSI (172 kPa)

On Pressure Drop

45 PSI (310 kPa)

On Pressure Drop

Nitrogen Supply

Regulator

35 PSI (242 kPa) 55 PSI (379 kPa)

Nitrogen Back-Up

Pressure Supervisory

Switch (E4)

30 PSI (207 kPa)

On Pressure Drop

50 PSI (345 kPa)

On Pressure Drop

.d Alarm Pressure Switch (C1) should activate when

pressurized to 4 to 8 psi (27 to 55 kPa) on pressure

rise. Alarm Pressure Switch (C1) is factory wired to

activate the water flow alarm.

Loading...

Loading...