Page 2 of 14

T

OTAL

P

AC

2

T

OTAL

P

AC

2 Integrated Fire Protection System

Air Supply

FM-086G-0-43E

1.2 Connecting the Air Compressor to AC power

The motor must be protected against short circuit, overload

and excessive temperature rise. Fuses, motor protective

switches and thermal protective switches provide the

necessary protection in these circumstances.

Fuses only serve as a short circuit protection of the motor

(wiring fault), not as protection against overload. Those are

provided and wired by the electrical contractor. An isolation

switch (for location detail, refer to Figure 2 in CONTROLS

Section) is also provided in the T

OTAL

P

AC

2 Cabinet and is

factory wired, allowing powering off the air compressor while

some maintenance work on the unit is done, without

disturbing the rest of the system.

Connect non-energized AC power to the air compressor.

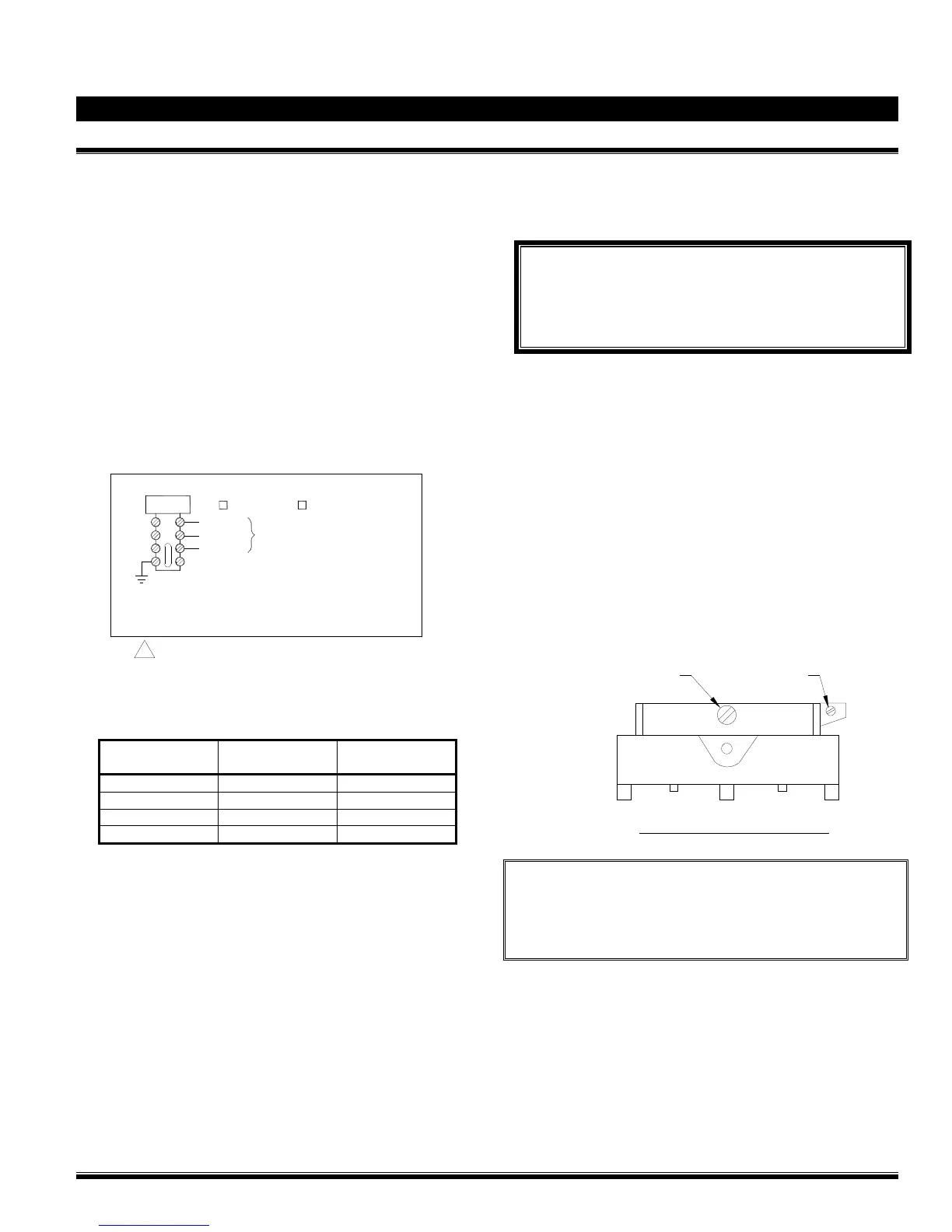

Refer to figure below and FIELD WIRING DIAGRAM.

4

2

1

TBB

NEUTRAL

GROUND

L1

AIR COMPRESSOR

1 HP Maximum

120Vac, 60Hz 220Vac, 50 Hz

Wiring size: Minimum 14 AWG with 600V Insulation.

Wiring of 120/220Vac Air Compressor

Power Source

INPUT POWER SOURCE

Branch circuit for air compressor shall not be the same

as the control panel power source

!

3

COMPRESSOR Amp rating

Compressor Size

(HP)

Amp. Rating at

120Vac – 60Hz

Amp. Rating at

220Vac – 50Hz

1/6 6.8 A 2.8 A

1/3 6.5 A 3.5 A

1/2 8 A 4.8 A

1 12.4 A 7.6 A

1.3 Operation

Air Supply Style "A":

1.3.1 To Apply Air Supply:

Establish AC power for the air compressor by activating the

correspondent circuit breaker at the electrical distribution

panel. Start compressor by activating the

compressor

isolating switch (E15) located in the control section of the unit

(refer to CONTROL SECTION, Fig. 2 for exact location of the

isolating switch).

If the air compressor motor fails to start or slows down under

load, shut the compressor off. Check that the supply voltage

agrees with the motor nameplate.

A Float Check Valve (E9) is provided with Air Option "A".

The Float Check Valve allows sensing of air pressure in the

system during supervisory times of the system.

1.3.2 To close air supply:

Turn off the compressor isolating switch (E15).

1.3.3 To adjust system air pressure (Furnas switch):

WARNING ! The cut-out/cut-in differential switch

adjustment screw (small screw to the right) is factory set.

DO NOT CHANGE ITS SETTING. Any unauthorised

modification of this setscrew adjustment will void the

system warranty and may also prevent the system from

operating normally.

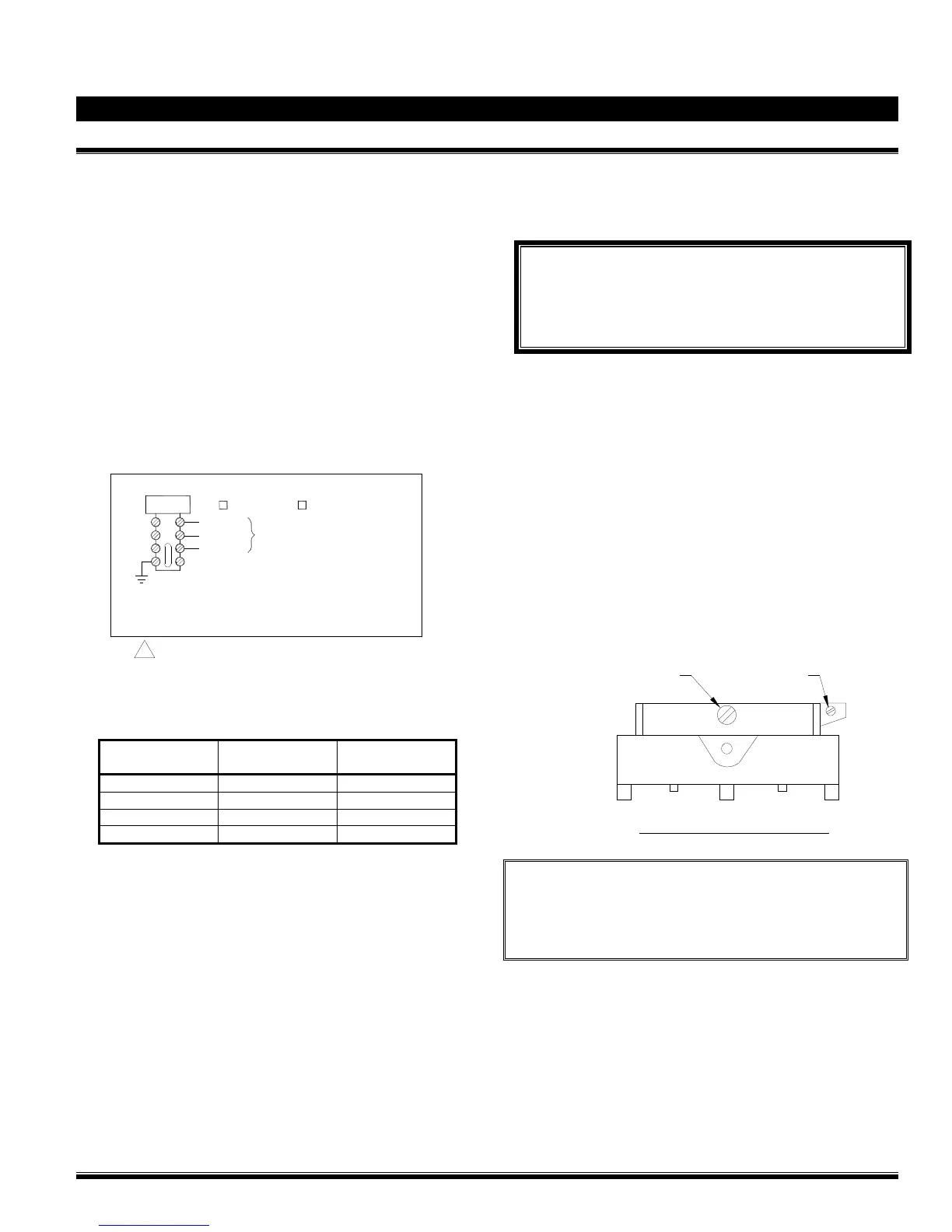

The air compressor cut-off pressure switch (E2) (shown

below with its metal cover removed) has its air compressor

cut-out adjustment switch (middle screw) factory set. This

switch should not need any adjustment but if necessary,

follow the instructions below:

a) Remove the metal cover of the compressor air

pressure switch (E2).

b) To raise the cut-out pressure of the air compressor,

turn the cut-out adjustment screw (middle) half a

turn CLOCKWISE.

c) Open the system main drain valve (D3) and let the

pressure drop until the air compressor (E1) restarts.

Check pressure reading on the system pressure

gauge (E3) when the air compressor stops again.

Repeat until the desired pressure is reached. Once

all done, replace the metal cover on the switch (E2).

Turn clockwise to increase

both cut-out and cut-in

pressure adjustment.

Factory set.

DO NOT CHANGE !

Front view of the Furnass Switch

(Part # 69HA3)

FM-072Q-0-109 A

Note: Do not turn the cut-out adjustment screw (middle)

all the way down in one shot. Proceed by steps.

Use the same method turning the cut-out

adjustment screw COUNTER-CLOCKWISE to

lower the air compressor cut-out pressure.

Loading...

Loading...