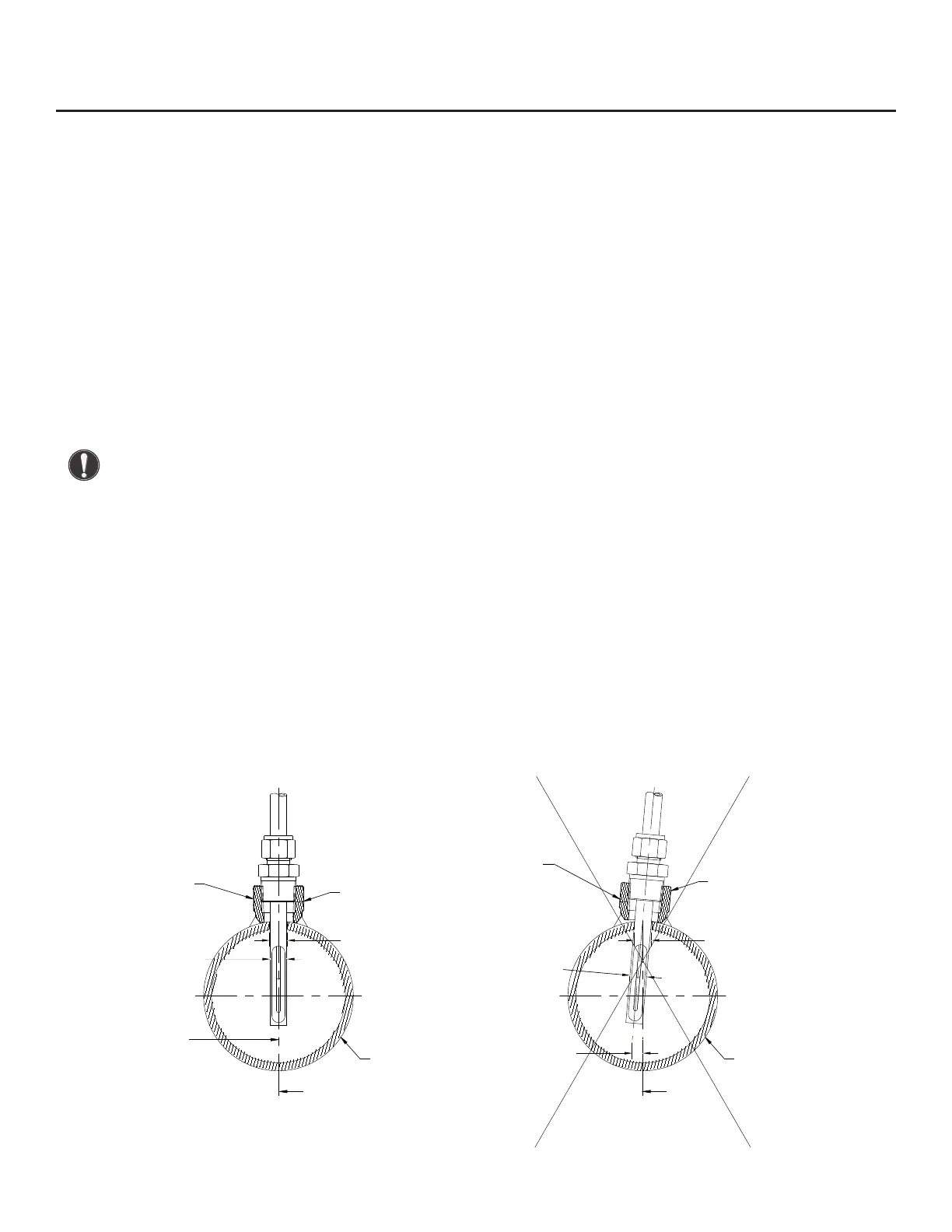

CENTERED

PIPE

CENTERLINE

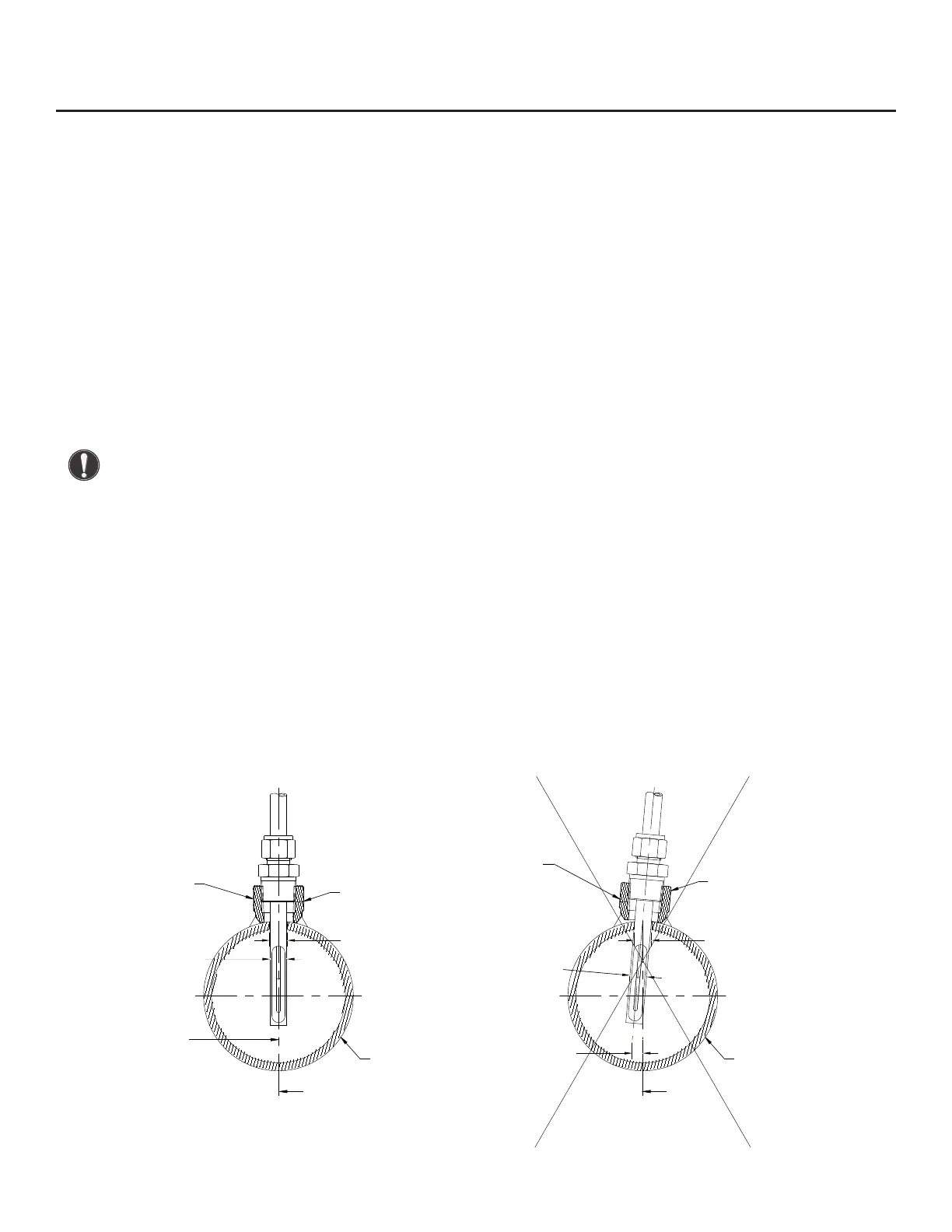

PIPE

CENTERLINE

OFF CENTER

DIA. 0.531

HOLE

DIA. 0.500

PROBE

DIA. 0.531

HOLE

DIA. 0.500

PROBE

CORRECT

INCORRECT

BRANCH, FEMALE,

3/4" NPT

BRANCH, FEMALE,

3/4" NPT

PIPE PIPE

Welding Branch Fitting to Pipe

The probe of the FT3 must be installed perpendicular in the pipe to measure ow accurately. Use the

following steps to ensure that the ¾" branch tting is correctly welded to the pipe.

Directions:

1. Drill a 0.531" (17/32") hole inside the tting through the wall of the pipe (1 wall only).

2. Assemble the compression tting and branch tting hand tight onto the probe of the FT3.

3. Insert the probe into the hole in the pipe and use the FT3 probe and compression tting to align

the branch tting with the hole and the probe perpendicular to the pipe.

4. Tack-weld the branch tting carefully onto the pipe.

• Before welding the tting completely, verify the probe is aligned to the center of the pipe and

the hole is centered in the branch tting (see Fig. 2.4).

5. To verify that the correct hole position has been achieved, carefully slide the 0.50" sensor in and

out of the branch tting and 0.531" hole.

WARNING! Do not force the 0.50" sensor through the 0.531" hole. Forcing it through the

hole can damage the probe!

6. Verify that the temporary weld of the branch tting positions the probe window on the pipe's

centerline.

• Fig. 2.4 shows an incorrect welding of the branch tting, causing the 0.50" sensor to be "o

center".

7. Once the branch tting is aligned properly, remove the 0.50" sensor from the branch tting and

nish welding. Then verify the probe is still aligned with the center of the pipe.

8. Set the depth of the ow meter (see "Fig. 2.5: Insertion Sensor Depth in Pipe" on page 24).

• Do not tighten compression tting until proper depth of ow meter is determined.

Fig. 2.4: Alignment of Branch Fitting

Installation | 23

Model FT3

Installation

Loading...

Loading...