VYPER

™

VARIABLE SPEED DRIVE

INSTALLATION

100-210 IOM (JUL 09)

Page 17

Installation

RIGGING AND HANDLING

Each Vyper

™

Variable Speed Drive unit is shipped mounted

on a wooden skid or mounted to the refrigeration package. All

shipping materials must be removed prior to unit installation.

The Vyper

™

cabinet unit is best moved via lifting lugs on the

top sides of the cabinet. Caution must be used to not damage

the pump or peripheral equipment on the rear of the cabinet.

Never move the unit by pushing against the Vyper

™

cabinet

with a forklift or other machinery.

UNIT (WITH FILTER) WEIGHTS (lb)

MODEL UNIT UNIT AS SHIPPED

700/572 1,890 2,319

912/752 2,026 2,455

VYPER

™

MOUNTING CONFIGURATIONS

NOTE: When mounting the Vyper

™

unit, allow space for

servicing both sides of the unit cabinet.

The Frick Vyper

™

is offered in two mounting configurations,

package mounted and remote mounted.

PACKAGE MOUNTED UNITS

One advantage of the package mounted version is that all

electrical connections have been prewired and tested at

the factory which ensures proper installation of control and

power lines. Package mounting is available for all horsepower

ratings of the Vyper

™

. Both water or glycol cooling connec-

tions are also available as well as the optional IEEE 519

harmonic filter. In addition, the package-mounted Vyper

™

does not require an additional dV/dt filter between the VFD

cabinet and the motor.

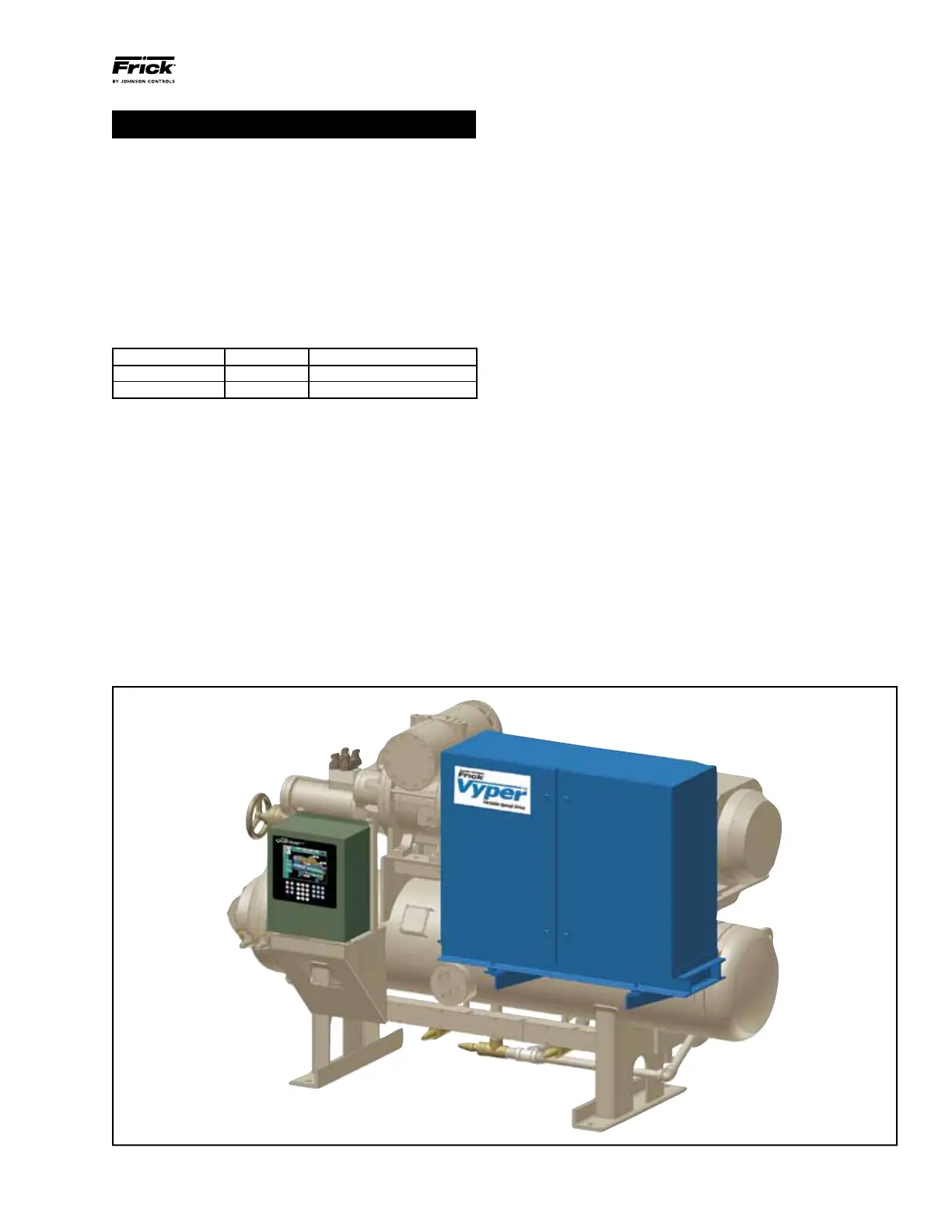

Figure 6 shows Vyper

™

cabinet mounted on a Frick RWF II

refrigeration package. Individual systems configurations will

vary according to model and horsepower sizes selected.

On package mounted units, the Vyper

™

cabinet is mounted

on a rectangular welded steel channel, which provides both

an attachment point for the cabinet’s side brackets and also

helps to maintain the rigidity of the cabinet during service.

The channel assembly / VSD cabinet is mounted on two

extension brackets welded to pads on the system’s oil separa-

tor. All package-mounted units are assembled with vibration

isolators located between the Vyper

™

channel frame and the

extension mounting brackets. The isolators help to minimize

the exposure of internal components and connections to

cyclic vibrations during unit shipping and operation.

Power supply to the Vyper

™

is from the top. Power supply to

the motor is made via a conduit exit from a rear panel in the

Vyper

™

Cabinet. Control wiring in/out is located at the lower

left side of the cabinet.

Please consult standard compressor package installation

procedures for this mounting method.

Drive Disconnect Height – covered under Exception 2,

section 8 of article 404 of the NEC, which states, Switches

and Circuit Breakers installed adjacent to motors, applianc-

es, or other equipment that they supply shall be permitted

to be located higher than 2.0 M (6 ft 7in) and to be acces-

sible by portable means.

Figure 6 - Vyper

™

Package Mounted on Frick RWF II. Diagram is for orientation purposes only and is not to scale.

Loading...

Loading...