VYPER

™

VARIABLE SPEED DRIVE

OPERATION

100-210 IOM (JUL 09)

Page 53

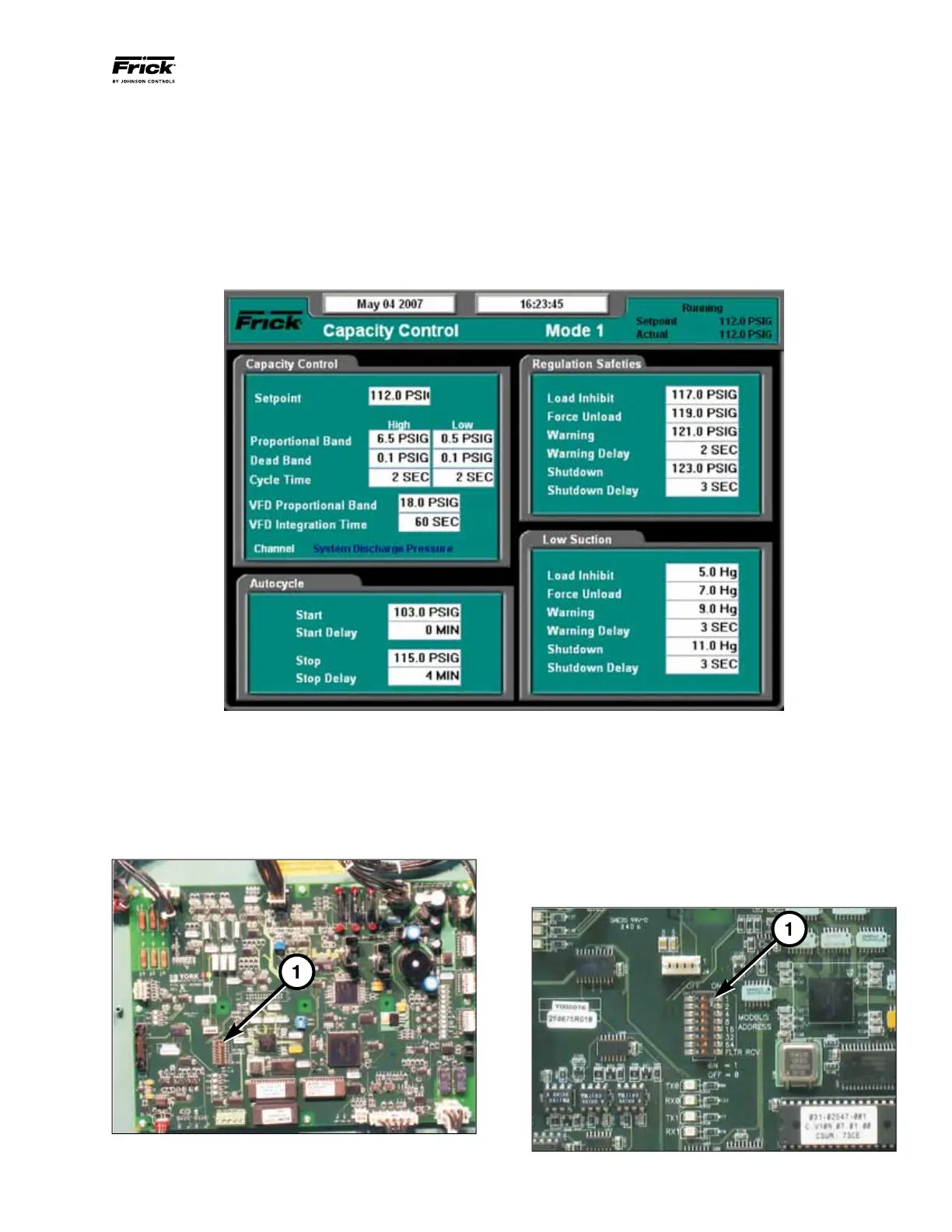

VSD LOGIC BOARD SETUP

The VSD logic board is equipped with a set of eight (8) DIP

switches (SW3), 1, that configure the RS-485 communication

between the logic board and Quantum

™

LX Panel as well as

the optional harmonic filter board. The logic board is mounted

inside the Vyper

™

cabinet. Refer to Figure 65.

Figure 65 - Vyper Logic Board

The first seven switches in SW3 configure MODBUS com-

munication address with the Quantum

™

LX Panel. To config-

ure the switches for proper communication, set switches 1

through 6 to the “OFF” position. Place switch 7 in the “ON”

position. The resulting MODBUS address is “0x40”. Refer

to Figure 65.

Switch 8 on SW3 allows harmonic filter communication.

Verify switch 8 is in the “ON” position to allow proper com-

munication. Refer to Figure 66.

Figure 66 - Logic Board SW3

With the actual pressure at 21psig the proportional com-

ponent would be 20%. The Proportional Component is

calculated as:

[(Actual Value – Setpoint) / PB] x (Maximum output – Mini-

mum Output).

[(21 – 20) / 4] x (100 – 20) = 20%

When this proportional component is added to the minimum

outpoint setpoint, the total output is 40% proportionally at

an actual value of 21 psig. It is the Integration Time setpoint

which will increase the output over time without an increase

in the actual value.

As long as the actual value (21 psig) does not change, the

Integration Time setpoint, in this case [30 sec], will increase

the output by the proportional component over every 30 sec-

onds to drive the actual value back to the Capacity Control

setpoint. If the actual value remains 21 psig, the Integration

Time Setpoint would increase the drive output to 100% over

1.5 minutes. (See Figure 64)

Figure 64 - Capacity Control Setpoints Screen

Loading...

Loading...