VYPER

™

VARIABLE SPEED DRIVE

INSTALLATION

100-210 IOM (JUL 09)

Page 34

ADDING AND REPLACING COOLANT

Irritant! Coolant is an irritant.

Always wear eye protection when

servicing the Vyper

™

cooling

system. Failure to do so may result in serious personal

injury.

The shipping fluid must sabe drained

from the

Vyper

™

cooling system

at

installation of drive and replaced with

new system running coolant. Failure to do so may result in

damage to the

Vyper

™

cooling system.

NOTE: Follow all Environmental Protection Agency (EPA)

and local guidelines for disposal of the

Vyper

™

shipping

fluid and coolant.

NOTE:

As part of preventative maintenance and for

proper operation, replace the coolant in the cooling

system once per year. The Frick part number for a one

gallon container of coolant is 013-02987-000.

The Vyper

™

is shipped from the factory with a premixed

shipping fluid containing a rust inhibitor that prevents corro-

sion of the internal cooling passages. The shipping fluid also

helps to keep the internal passages free from contaminants.

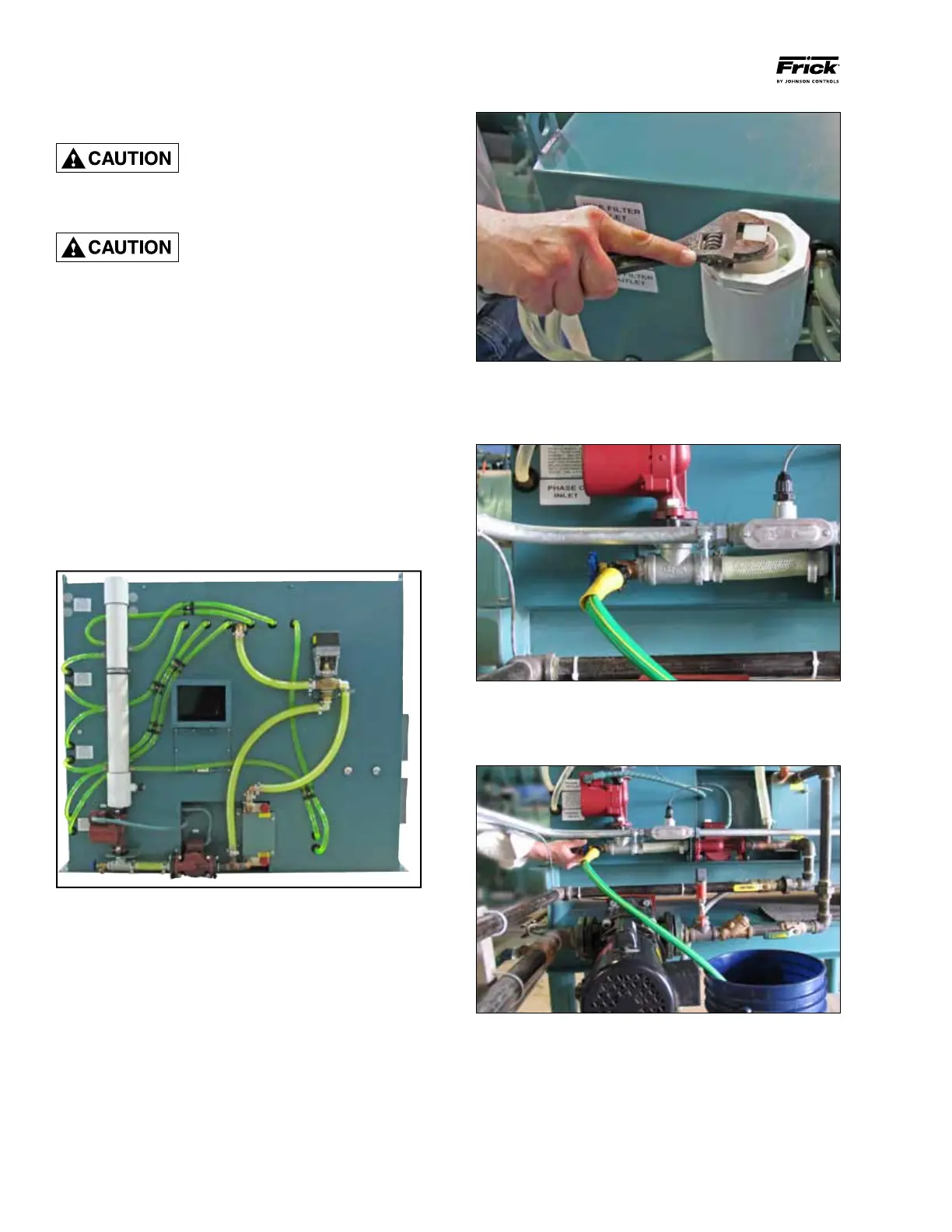

The illustration in Figure 26 shows the cooling circuit of a

remote-mounted water-cooled Vyper

™

. The cooling circuit for

the glycol-cooled version is identical.

Figure 26 - Coolant Circulation System

Prior to starting the Vyper

™

for the first time, drain and replace

the shipping fluid from the Vyper

™

cooling system with new

running coolant appropriate for the type of system the Vyper

™

is equipped with. Perform the steps in the following procedure

to replace or add coolant to the system.

Step 1: (See Figure 27) Disconnect power from the VSD.

Remove the pipe plug from the top of the exit manifold with

an adjustable wrench. This allows air to enter the system

and displace the fluid during draining.

Figure 27 - Removing the Cooling System Pipe Plug

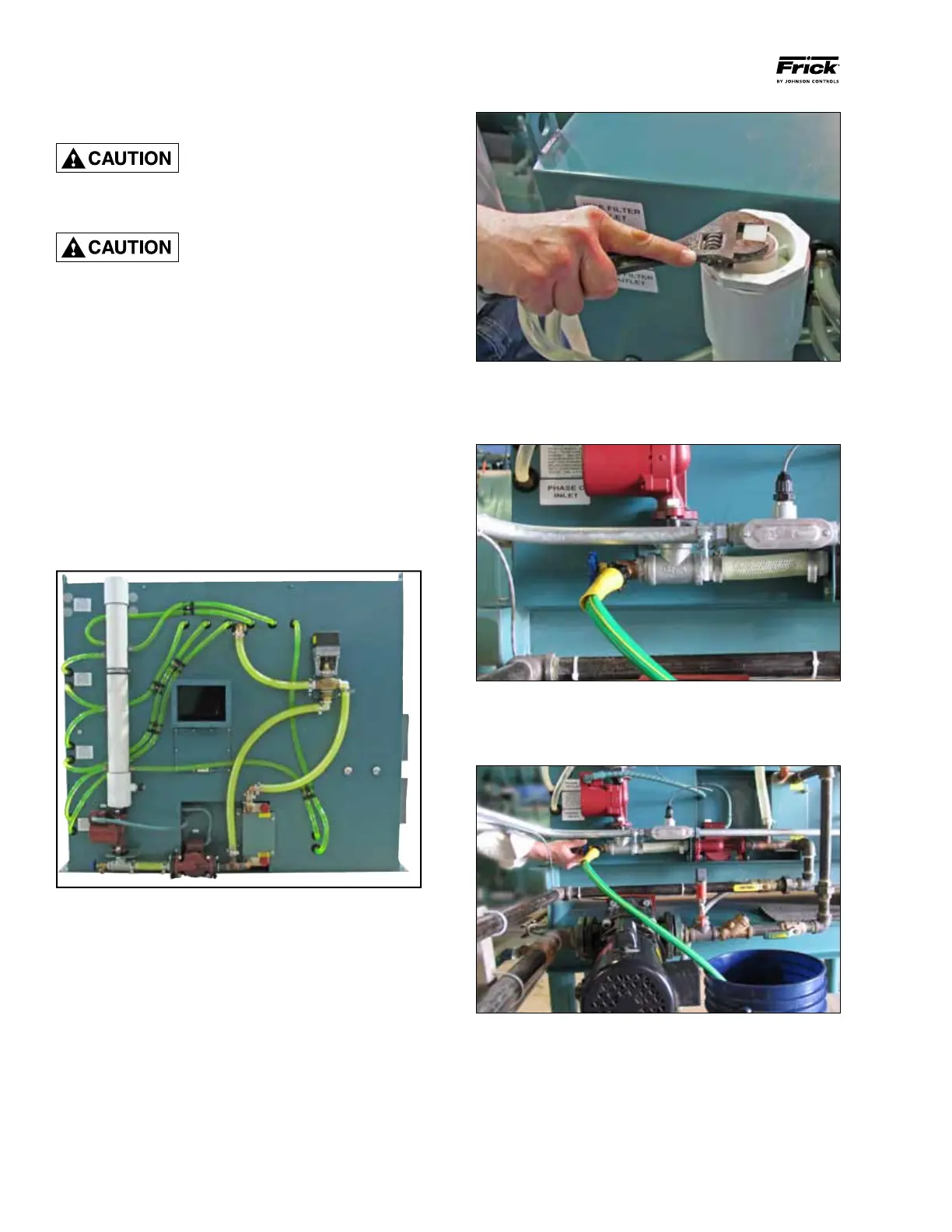

Step 2: (See Figure 28) Connect a hose fitting to the drain

of the heat exchanger. Be sure that the hose is connected

tightly to the drain fitting so no fluid is spilled.

Figure 28 - Hose connected to the Heat Exchanger Drain

Step 3: (See Figure 29) Open the drain valve and allow the

fluid to drain from the loop. Catch buckets should be able to

hold approximately 4 gallons of liquid.

Figure 29 - Draining Coolant

Loading...

Loading...