Fröling Heizkessel- und Behälterbau Ges.m.b.H, Industriestrasse 12, A-4710 Grieskirchen Page 17

Tel +43 (0) 7248 606-0 Fax +43 (0) 7248 606-600 info@froeling.com www.froeling.com B0430207

2.3.5 Combination with storage tank

We recommend that you use the pellet boiler with a storage tank, as this

allows you to achieve a reduction in start-up and shut downs within the ideal

performance range of the boiler.

Please contact your installer or a Fröling technician directly for the right

measurements of the storage tank.

If your P4 Pellet boiler has been installed with a Thermal Storage

System, this system may require periodic maintenance. Please review

the periodic maintenance requirements of your thermal storage system

with your installer.

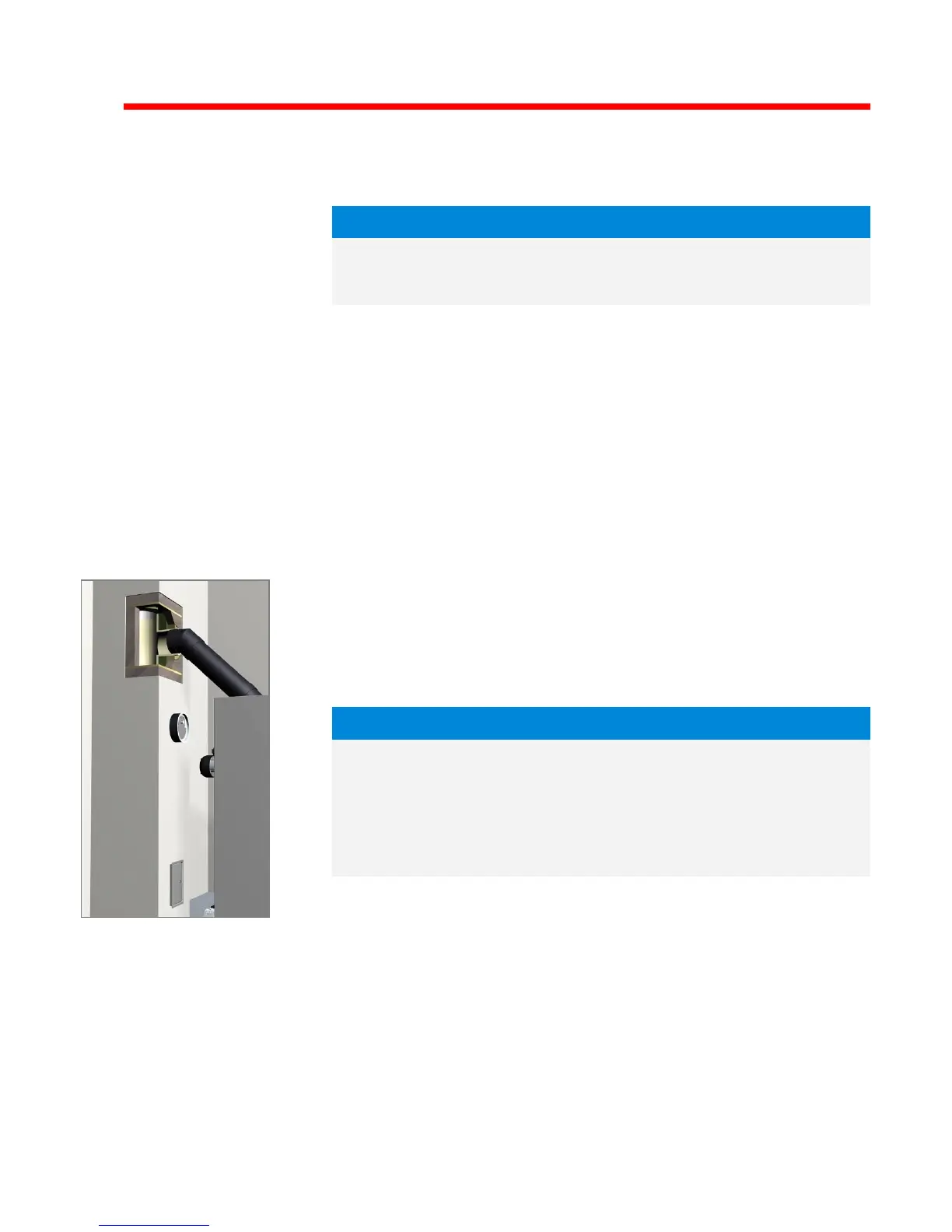

2.3.6 Chimney connection / chimney system

The chimney is one of the most critical factors in the successful

operation of any solid fuel heater, including the Fröling P4 boiler. A good

chimney will provide a continuous and dependable draft to pull the

exhaust gasses out of the building. The entire flue gas system must be

designed to prevent, wherever possible, damage caused by seepage,

insufficient feed pressure and condensation. Follow manufacturer’s

installation instructions for installing and supporting any specific

chimney product.

The boiler must be connected to a tile-lined masonry chimney or to a factory-

built Type UL 103 HT (ULC S629 in Canada) approved chimney. The chimney

must be in good condition. If the boiler is connected to a dirty or inadequate

chimney, it can present a serious fire hazard. All chimneys and connections

must conform to NFPA standard #211. No other appliance should be

connected to this flue unless allowed by the local code authority. Consult your

local inspector for chimney requirements and install the boiler in accordance

with all applicable codes.

Flue gas exhaust temperatures can be low enough to cause

condensation in chimneys. Condensation will, over time, damage a

masonry chimney. Accordingly, installation of a stainless chimney liner

(made with 304, 316, or 321) inside the chimney flue is strongly

recommended.

The flue gas temperatures (when cleaned) and the additional flue gas

values can be found in the technical specification sheets (See chart

below “see chart below “Boiler data for constructing the flue gas

system”.

The smoke pipe connecting the boiler to the chimney flue must be black

or stainless, have a minimum thickness of 24 gauge, and rise a

Loading...

Loading...