13 SEP 12

/ Battery Charging Systems / Welding Technology / Solar Electronics

Quality (

Quality (Quality (

Quality (

standard or high

⁄

⁄⁄

⁄

This trait refers to the tolerance of

the wire diameter the tip is designed

for. Standard

StandardStandard

Standard quality tips have a

much looser tolerance than High

High High

High

Quality

QualityQuality

Quality tips. High Quality

High QualityHigh Quality

High Quality tips wear

at a slower rate than Standard

StandardStandard

Standard

quality tips.

Thread Size (

Thread Size (Thread Size (

Thread Size (

M6, M8, and M10

⁄

⁄⁄

⁄

This trait refers to the size of the

threads the contact tip will screw

into. M8 and M10 are typical sizes

for most MIG applications.

Wire Size (

Wire Size (Wire Size (

Wire Size (

see below

⁄

⁄⁄

⁄

The wire size refers to the diameter

of the wire the tip is designed for.

This size can be either standard

(US⁄ or metric (EU⁄. Basic sizes

used in the US are

Fraction

FractionFraction

Fraction Standard

StandardStandard

Standard Metric

MetricMetric

Metric

- - - .035 .9

3/64 .045 1.2

1/16 .062 1.6

Bore Size (

Bore Size (Bore Size (

Bore Size (

none, Center-Bore

⁄

⁄⁄

⁄

This trait refers to how the inner

linger fits into the contact tip. This

is critical with Aluminum wire

especially.

None

NoneNone

None: There is no center bore,

the contact tip end is cone

shaped to guide the wire through

the tip.

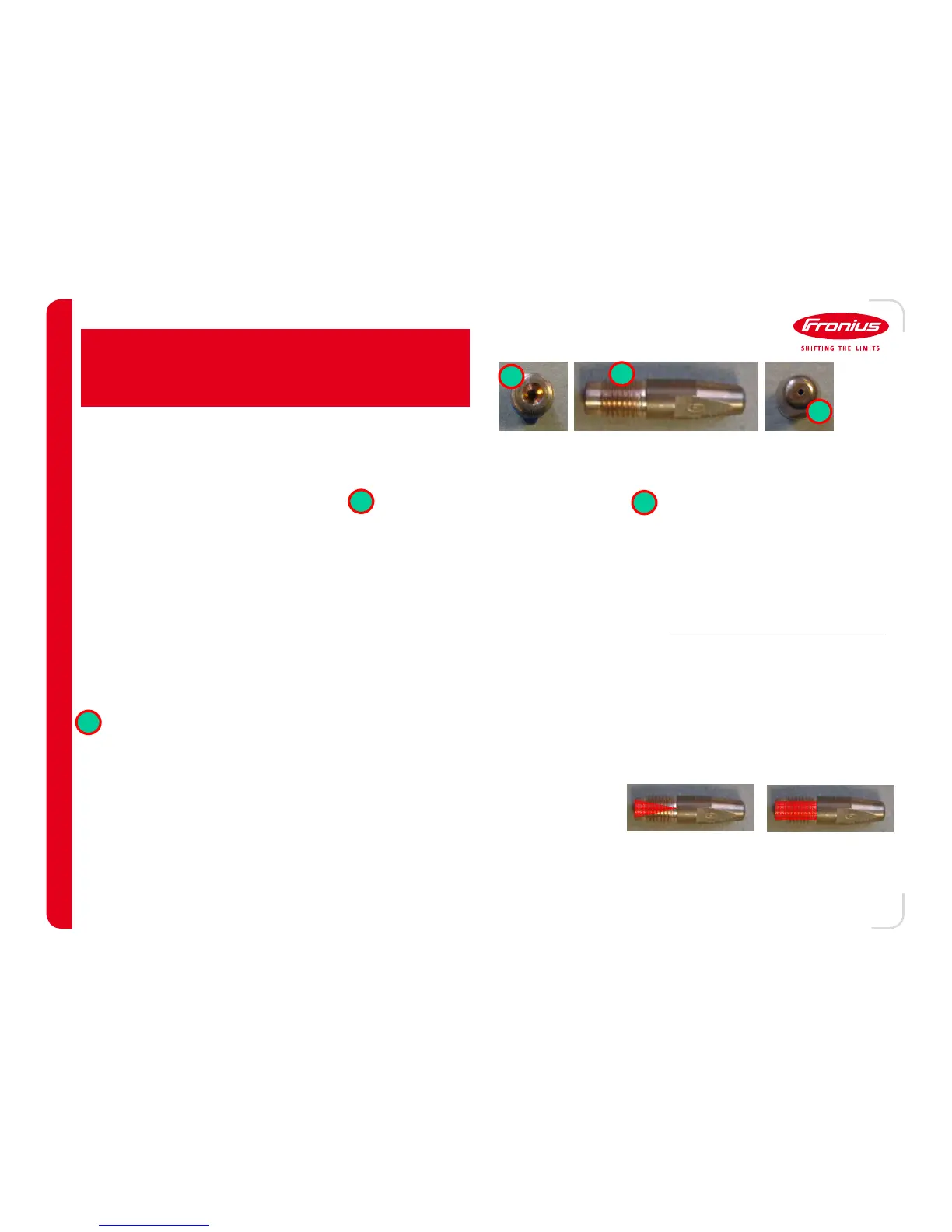

Center Bore (

Center Bore (Center Bore (

Center Bore (

CB

⁄

⁄⁄

⁄: The contact tip

is squared off internally (see

figure 2⁄ and will come in one of

two sizes (4.1mm or 4.8mm⁄

depending on the size of the

inner liner.

CB tips are required for aluminum

welding. This type of tip allows

the liner to be exactly centered in

the tip.

Figure 2: no bore versus center-bore

1

11

1

2

22

2

3

33

3

1

11

1

2

22

2

3

33

3

Consumables

Contact Tips

-

--

- 63

63 63

63 -

--

-

Loading...

Loading...