58

5 Damage prevention

5.3 Corrosion protection measures

MITSUBISHI FUSO body/equipment mounting directives for FE Issue date: 20. 10. 2020

! Only print out complete sections from the current version

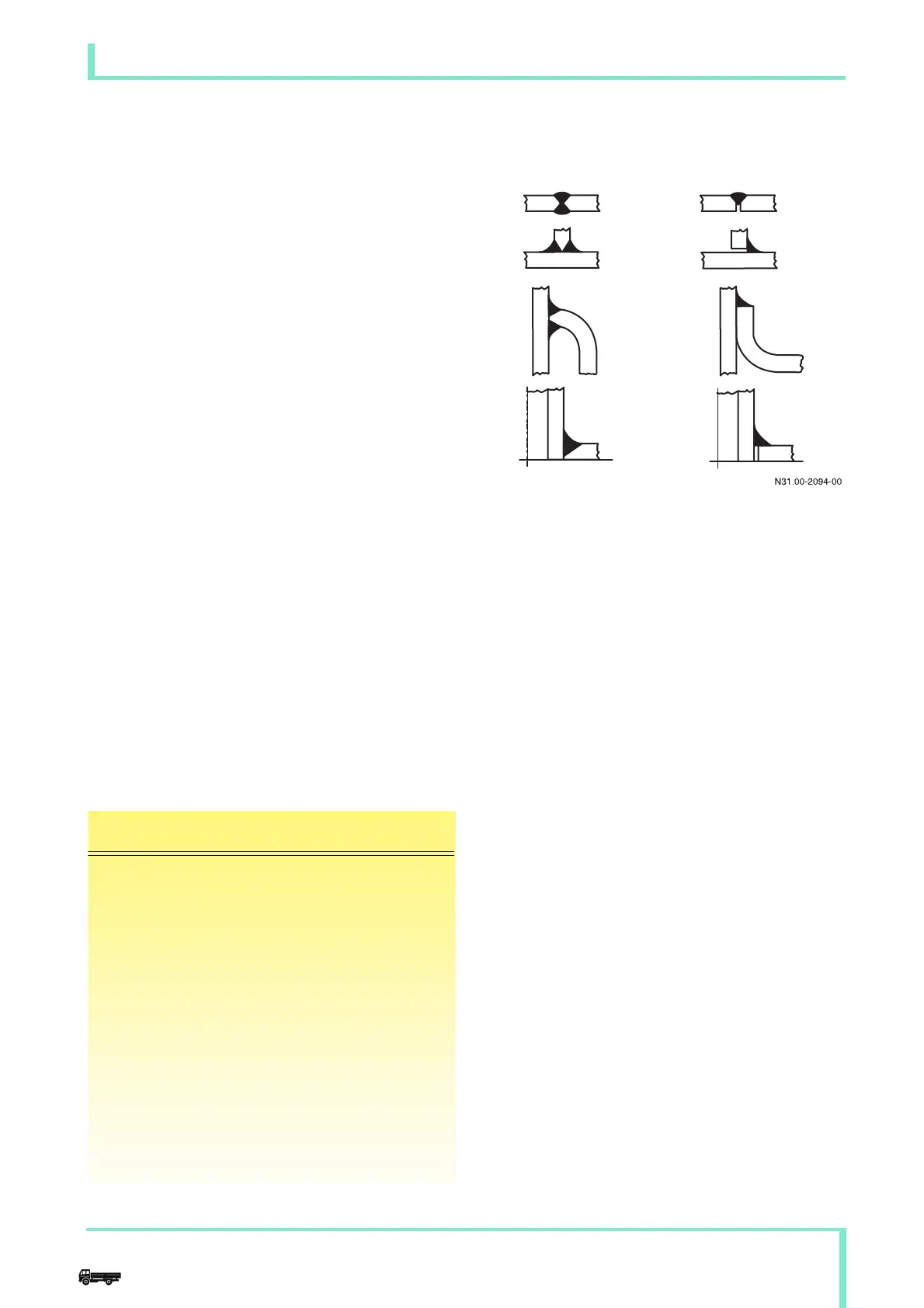

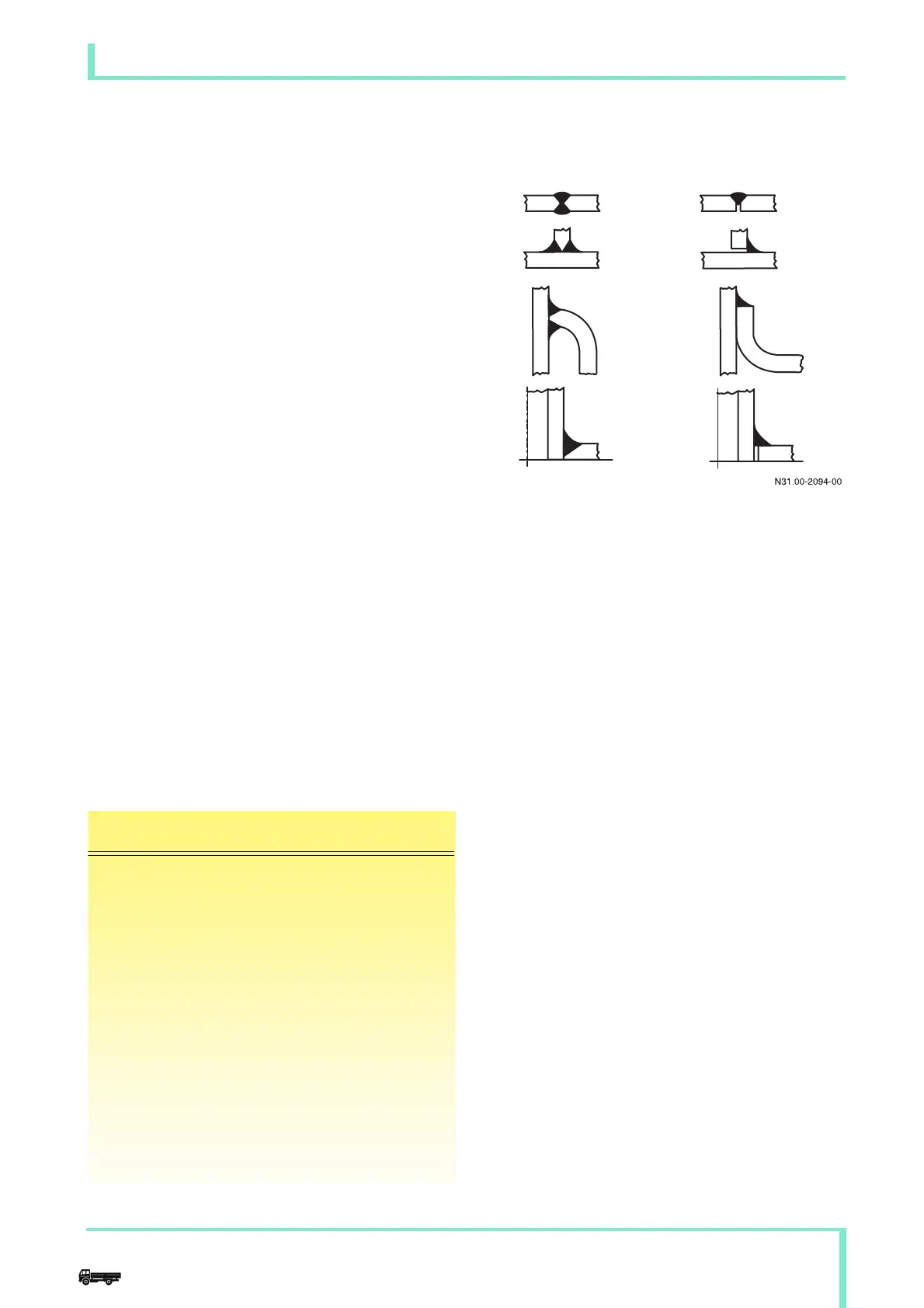

Corrosion prevention in welding work

In order to avoid crevice corrosion at weld seams, the

welds should be made in accordance with the

examples shown.

Preparation

The welding area must be free from corrosion, grease,

dirt or similar contamination. If painted surfaces are to

be welded, the paint coat must first be removed by

grinding or chemical stripping. If this is not done, the

paint will burn and the residues can impair corrosion

resistance.

After welding work

• Remove drilling shavings.

• Deburr sharp edges.

• Remove any burned paint and thoroughly prepare

surfaces for painting.

• Prime and paint all unprotected parts.

• Preserve cavities with wax preservative.

• Carry out corrosion protection measures on the

underbody and frame parts.

i Additional information

Plug and slot welds, particularly on horizontal

surfaces, should be avoided due to the risk of corro-

sion. If they are unavoidable, these welds must

receive additional preservation. Furthermore, avoid

designs which allow moisture to accumulate. These

must be fitted with additional drainage holes or

gaps in the weld seam.

Example: Weld seams

A – Suitable

B – Unsuitable

Loading...

Loading...