172

8.5 Electric circuit continuity check

8 Electrics/electronics

MITSUBISHI FUSO body/equipment mounting directives for FE Issue date: 20. 10. 2020

! Only print out complete sections from the current version

8.5 Electric circuit continuity check

8.5.1 Check procedures

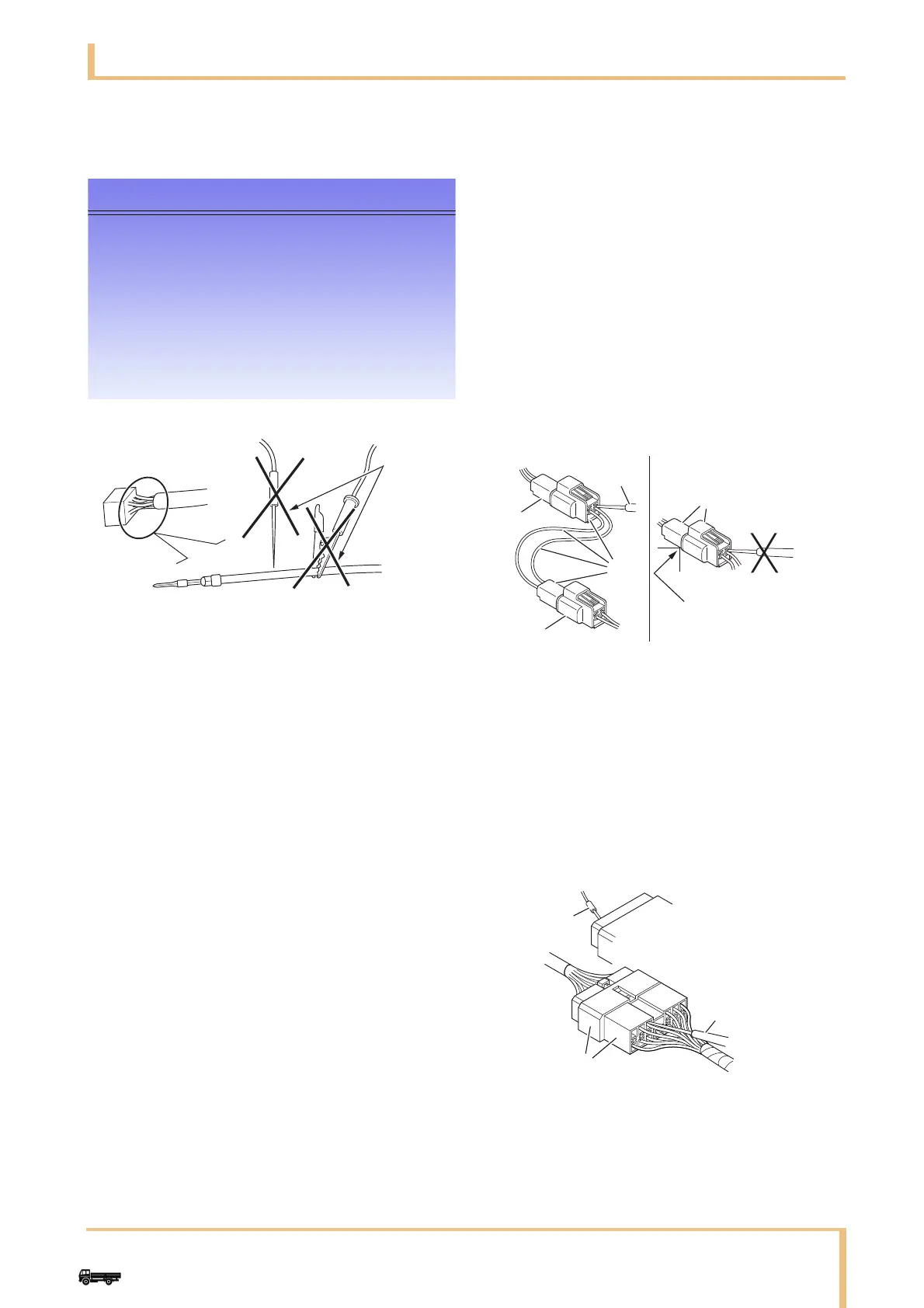

Continuity check with mating connectors joined

(with continuity established in circuit)

Waterproof connector

• Connect check harness A between joined circuit

connectors B.

• Perform the check with the test bar applied to the

check harness A connector

• Do not put in the test bar from connector B-side

harness. The connector would lose waterproofing

performance to result in harness corrosion.

Non-waterproof connector

• Insert the test bar from the harness side.

• If joined connectors are so small that test bar

cannot be inserted, such as control unit

connectors, do not push in the test bar by force but

use a superfine pointed test bar.

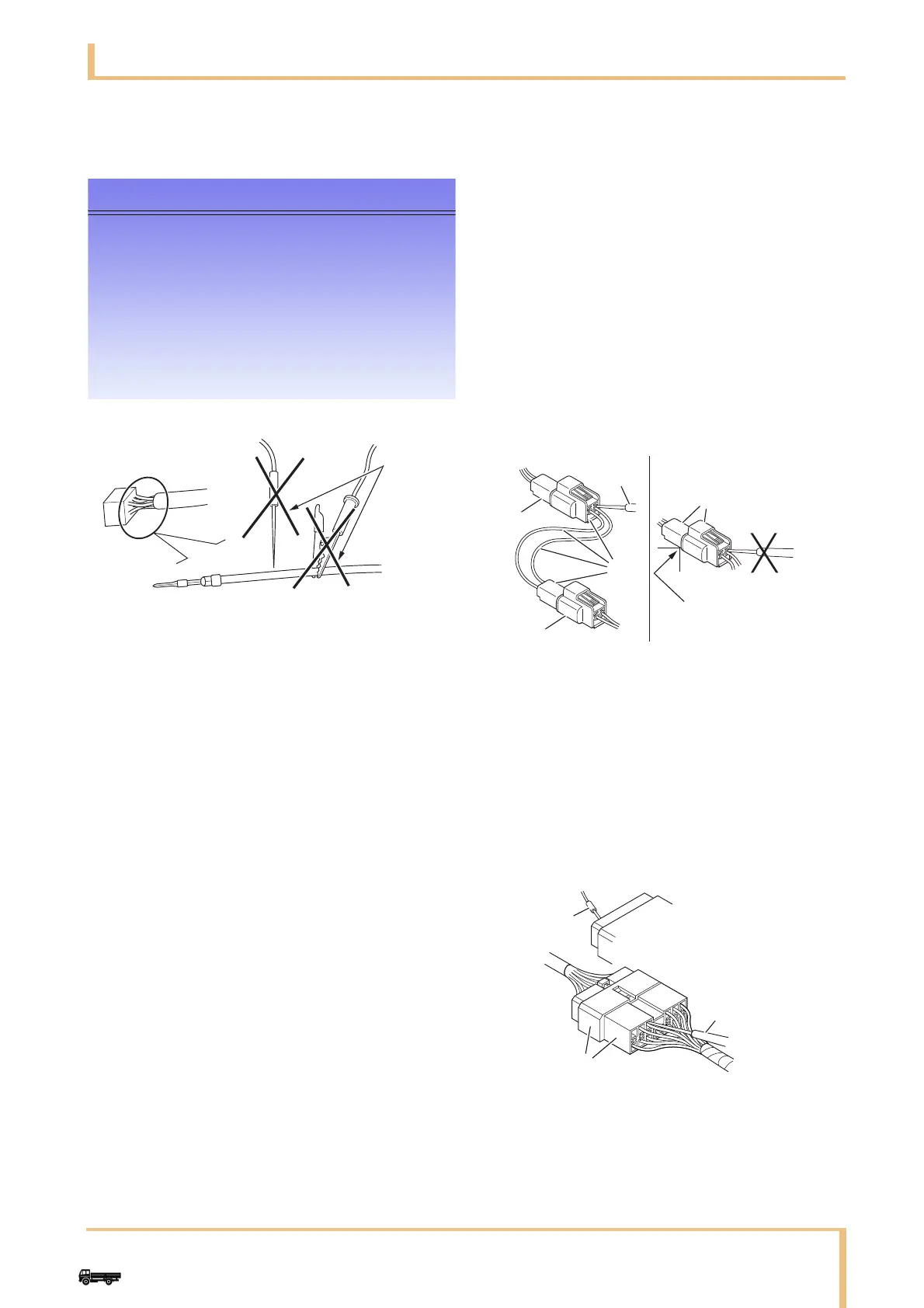

! Property damage

Needling check is prohibitive.

Damage to cable insulation by test bar or electric

circuit check lamp needle can result in premature

corrosion of chassis harness.

1 Sticking of test bar or electric circuit check lamp

needle into cable insulation is prohibitive.

1 Connect A between B here.

1Test bar

2 Connector

3Test bar

Loading...

Loading...